Rotary Dryer Manufacturer in India – Shalimar Engineering

Shalimar Engineering is a recognized rotary dryer manufacturer in India, delivering industrial drying solutions designed for continuous and heavy‑duty operations. With strong expertise in mechanical design and fabrication, the company manufactures rotary dryers that are suitable for demanding industrial environments where reliability and consistent performance are essential.

A rotary dryer is a critical piece of equipment used across multiple industries to reduce moisture content from bulk materials. Shalimar Engineering focuses on designing rotary dryer systems that meet specific process requirements while maintaining mechanical stability, thermal efficiency, and long operational life.

Importance of Rotary Dryer in Industrial Processing

In industrial manufacturing, moisture content plays a significant role in material handling, storage, and product quality. Excess moisture can lead to material agglomeration, reduced flowability, and processing inefficiencies. An industrial rotary dryer helps overcome these challenges by providing uniform and controlled drying of materials.

Rotary dryers are widely preferred in industrial operations because they can handle large capacities, variable feed rates, and different material sizes. Shalimar Engineering designs rotary dryers that operate reliably even under fluctuating production conditions, making them suitable for continuous processing plants.

Engineering Expertise of Shalimar Engineering

As an experienced rotary dryer manufacturer, Shalimar Engineering follows a process‑oriented engineering approach. Each rotary dryer is designed after detailed analysis of material properties such as bulk density, abrasiveness, moisture content, and drying temperature requirements.

Key parameters including drum diameter, drum length, rotational speed, and internal flight configuration are carefully selected. This ensures effective heat transfer and uniform drying while minimizing wear on mechanical components. Such engineering precision helps industries achieve stable output quality and reduced downtime.

Heavy‑Duty Construction of Industrial Rotary Dryer

The industrial rotary dryer manufactured by Shalimar Engineering is built using high‑quality raw materials suitable for long‑term industrial use. The dryer shell is fabricated using robust steel plates that provide strength and resistance to thermal and mechanical stress.

The rotating drum is supported on heavy‑duty trunnion rollers designed to carry high loads smoothly. Proper alignment and balanced construction help reduce vibration during operation, which improves bearing life and overall equipment reliability.

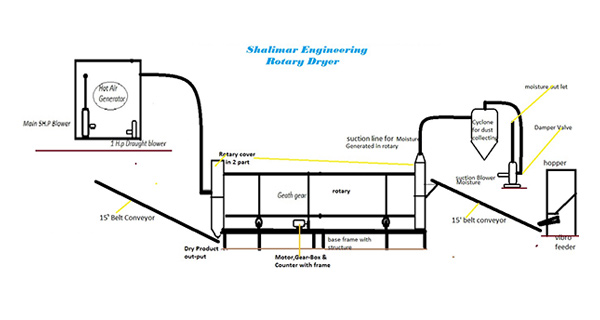

Working Principle of Rotary Dryer

The working principle of a rotary dryer is based on continuous rotation and controlled heat exposure. Wet material is fed into the dryer through the inlet section. As the drum rotates, internal lifting flights lift the material and allow it to cascade through the hot gas stream.

This cascading action ensures maximum contact between material and heat, resulting in uniform moisture evaporation. As the material progresses through the length of the drum, it gradually reaches the desired moisture level before being discharged at the outlet. Exhaust gases are handled through dust collection systems to maintain a clean working environment.

Types of Rotary Dryers Offered

Shalimar Engineering manufactures different types of rotary dryers based on application requirements. As a reliable rotary dryer manufacturer, the company supplies both direct‑fired and indirect‑fired rotary dryers.

Direct‑fired rotary dryers are suitable for materials that can safely come into contact with hot gases. Indirect‑fired rotary dryers are used for heat‑sensitive or contamination‑sensitive materials where the heating medium does not directly contact the product. Co‑current and counter‑current flow designs are also provided depending on thermal efficiency and material behavior.

Industrial Applications of Rotary Dryer Systems

Shalimar Engineering supplies rotary dryer systems for a wide range of industries. These include mineral processing plants, cement manufacturing units, fertilizer plants, chemical industries, and sand processing facilities.

Common materials dried using rotary dryers include limestone, gypsum, bentonite, bauxite, fertilizers, industrial salts, and aggregates. This wide range of applications has positioned Shalimar Engineering among dependable rotary dryer suppliers serving diverse industrial sectors.

Customized Rotary Dryer Manufacturing

Every industrial process has unique drying requirements. Shalimar Engineering understands this and offers customized rotary dryer solutions tailored to specific material and capacity needs.

Customization options include drum size, shell thickness, material of construction, internal flight design, burner selection, and drive mechanism. This flexibility ensures that the rotary dryer delivers consistent drying performance while operating efficiently within the customer’s production setup.

Energy Efficiency and Thermal Performance

Energy efficiency is a critical consideration in industrial drying operations. Shalimar Engineering designs industrial rotary dryers with optimized airflow patterns and controlled heat utilization to achieve effective moisture removal.

Proper insulation, suitable heating systems, and well‑designed exhaust arrangements help maintain stable operating temperatures. These design features support controlled energy consumption and reliable drying performance during continuous operation.

Technical Specifications of Rotary Dryer

The rotary dryer manufactured by Shalimar Engineering is available in various configurations depending on application and capacity. Typical technical specifications are outlined below.

| Parameter | Specification |

|---|---|

| Equipment Type | Industrial Rotary Dryer |

| Application | Minerals, Chemicals, Fertilizers, Sand, Bulk Materials |

| Drum Diameter | 800 mm to 4000 mm |

| Drum Length | 6 meters to 30 meters |

| Shell Material | Mild Steel / Carbon Steel / Stainless Steel |

| Shell Thickness | 8 mm to 25 mm |

| Capacity Range | 1 TPH to 50 TPH |

| Operating Temperature | Up to 800°C (Material Dependent) |

| Heating System | Direct Fired / Indirect Fired |

| Burner Type | Oil, Gas, Coal, Hot Air Generator |

| Drive System | Geared Motor with Chain / Girth Gear |

| Drum Speed | 1 to 6 RPM |

| Internal Flights | Lifting and Cascading Type |

| Support System | Heavy-Duty Trunnion Rollers |

| Dust Collection | Cyclone Separator / Bag Filter (Optional) |

| Power Supply | 415 V, 50 Hz |

| Control System | Manual / PLC Based |

Specifications may vary based on process requirements.

Manufacturing Quality and Inspection

Shalimar Engineering follows strict quality control procedures throughout the manufacturing process. Raw materials are inspected before fabrication, and all critical welding joints are checked for strength and durability.

Each rotary dryer undergoes dimensional verification, alignment inspection, and trial rotation before dispatch. These checks help ensure that the equipment performs reliably under actual operating conditions.

Installation and Commissioning Support

Proper installation plays a key role in the performance of an industrial rotary dryer. Shalimar Engineering provides technical assistance during installation and commissioning to ensure correct alignment and smooth startup.

The support team assists with trial runs and operational guidance, helping industries achieve stable production from the initial stage of operation.

Maintenance and Long‑Term Reliability

Shalimar Engineering designs rotary dryers with accessibility in mind, allowing easy inspection and routine maintenance. Critical components such as rollers, bearings, and seals are positioned for convenient servicing.

Availability of spare parts and technical support further strengthens the company’s reputation among reliable rotary dryer suppliers serving long‑term industrial projects.

Position Among Rotary Dryer Manufacturers in India

Among rotary dryer manufacturers in India, Shalimar Engineering is known for delivering equipment that balances performance, durability, and cost efficiency. The company follows proven industrial design practices aligned with global standards while keeping Indian operating conditions in focus.

This approach makes Shalimar Engineering a preferred rotary dryer manufacturer for both domestic and export‑oriented projects.

Trusted Industrial Rotary Dryer Supplier

Shalimar Engineering continues to support industries with dependable industrial rotary dryer solutions backed by engineering expertise and quality manufacturing. The company’s commitment to reliable performance and technical support has built long‑term relationships with clients across multiple sectors.

Industries seeking stable drying operations and durable equipment rely on Shalimar Engineering as one of the trusted rotary dryer suppliers in the market.

Rotary dryers can process a wide range of materials including minerals, ores, chemicals, agricultural products, biomass, sludge, and industrial by-products. Material testing helps determine the optimal dryer configuration.

Direct dryers allow material to contact hot gases directly, offering higher efficiency. Indirect dryers heat the drum externally, suitable for heat-sensitive or contamination-prone materials.

Residence time varies from 15 minutes to several hours depending on material properties, initial moisture content, desired final moisture, and dryer specifications.

With proper maintenance, industrial rotary dryers can operate reliably for 20-30 years. Regular inspections and timely component replacement ensure long service life.

Yes, we offer comprehensive after-sales services including spare parts, maintenance support, troubleshooting assistance, and performance optimization consultations.

Contact the Trusted Rotary Dryer Supplier Today

If you are looking for a reliable Rotary Dryer Manufacturer in India, Shalimar Engineering is your trusted partner. With years of expertise, state-of-the-art manufacturing, and a commitment to customer success, we deliver solutions that combine quality, efficiency, and durability.

Contact Us Today to discuss your requirements with our team and get a customized quote from the leading Rotary Dryer Manufacturer in Ahmedabad, Gujarat, India.

Tags:- Rotary Dryer Exporter in Bahrain, Rotary Dryer Exporter in Iran, Rotary Dryer Exporter in Iraq, Rotary Dryer Exporter in Kuwait, Rotary Dryer Exporter in Oman, Rotary Dryer Exporter in Qatar, Rotary Dryer Exporter in Saudi Arabia, Rotary Dryer Exporter in Yemen, Continuous Rotary Dryer Exporter in Bahrain, Continuous Rotary Dryer Exporter in Iran, Continuous Rotary Dryer Exporter in Iraq, Continuous Rotary Dryer Exporter in Kuwait, Continuous Rotary Dryer Exporter in Oman, Continuous Rotary Dryer Exporter in Qatar, Continuous Rotary Dryer Exporter in Saudi Arabia, Continuous Rotary Dryer Exporter in Yemen, Batch Type Rotary Dryer Manufacturer, Batch Type Rotary Dryer Manufacturer in Ahmedabad, Batch Type Rotary Dryer Manufacturer India, Rotary Dryer Manufacturer, Rotary Dryer Manufacturer in Ahmedabad, Rotary Dryer Manufacturer in India, Rotary Dryer Exporter in India, Rotary Dryer Exporter in Bangladesh, Rotary Dryer Exporter in Bahrain, Rotary Dryer Exporter in Hong Kong, Rotary Dryer Exporter in Indonesia, Rotary Dryer Exporter in Iran, Rotary Dryer Exporter in Iraq, Rotary Dryer Exporter in Israel, Rotary Dryer Exporter in Jordan, Rotary Dryer Exporter in Kuwait, Rotary Dryer Exporter in Lebanon, Rotary Dryer Exporter in Malaysia, Rotary Dryer Exporter in Mongolia, Rotary Dryer Exporter in Oman, Rotary Dryer Exporter in Pakistan, Rotary Dryer Exporter in Philippines, Rotary Dryer Exporter in Qatar, Rotary Dryer Exporter in Saudi Arabia, Rotary Dryer Exporter in South Korea, Rotary Dryer Exporter in Taiwan, Rotary Dryer Exporter in Turkey, Rotary Dryer Exporter in UAE, Rotary Dryer Exporter in Vietnam.