Iron & Other Ore Pelletizing Plant - Manufacturer & Supplier

Shalimar Engineering stands as a trusted manufacturer and supplier of complete pellet plant solutions, delivering advanced equipment and technology for iron ore agglomeration. Our comprehensive iron ore pelletizing plant systems transform fine ore concentrates into high-quality, uniform pellets that meet the stringent requirements of blast furnace and direct reduction operations worldwide.

The pellet process has revolutionized the iron and steel industry by converting iron ore fines previously considered waste material into valuable feedstock. A well-designed pellet plant combines multiple equipment systems working in harmony to produce pellets with consistent size, strength, and metallurgical properties. As an experienced manufacturer and supplier, we provide end-to-end solutions from initial engineering through commissioning and ongoing support.

Technical Specifications of Our Pelletizing Plant Systems

Iron Ore Pelletizing Plant - Standard Specifications

| PARAMETER | SPECIFICATION | DETAILS |

|---|---|---|

| Plant Capacity | 0.5 MTPA to 10 MTPA | Customizable based on requirements |

| Pellet Size | 8–16 mm | Standard range, adjustable |

| Green Pellet Strength | 800–1200 gm/pellet | Drop number: 4–6 times |

| Fired Pellet Strength | >250 kg/pellet | Compression strength |

| Moisture Content | 8–10% | In green pellets |

| Basicity Range | 0.5 to 2.5 | CaO/SiO₂ ratio |

| Iron Content | 62–67% Fe | In finished pellets |

| Balling Drum Diameter | 3.0 m to 4.5 m | Based on capacity |

| Balling Drum Length | 8 m to 14 m | Optimized for retention time |

| Induration Temperature | 1250–1350°C | Peak firing temperature |

| Fuel Options | Coal, Natural Gas, LPG | Multiple fuel flexibility |

| Power Consumption | 35–45 kWh/ton | Of finished pellets |

| Automation Level | PLC / DCS Based | Fully automated systems |

| Material Handling | Complete Integration | From raw material to finished product |

Disc Pelletizer Specifications (Alternative System)

| PARAMETER | SPECIFICATION |

|---|---|

| Disc Diameter | 3000 mm to 5000 mm |

| Disc Inclination | 45° to 52° (adjustable) |

| Rotational Speed | 8–12 RPM (variable) |

| Motor Power | 30 HP to 75 HP |

| Capacity | 20–150 TPH |

| Scraper System | Automatic cleaning |

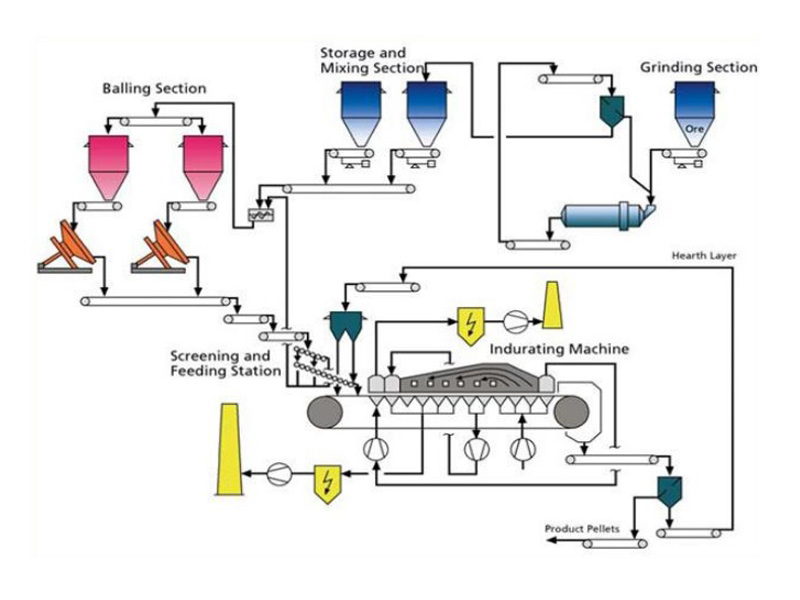

Complete Iron Ore Pelletizing Process Explained

The iron ore pelletizing process represents a sophisticated metallurgical operation that converts fine iron ore particles into spherical, hardened pellets. Understanding each stage helps operators optimize production and maintain consistent product quality throughout the pellet processing cycle.

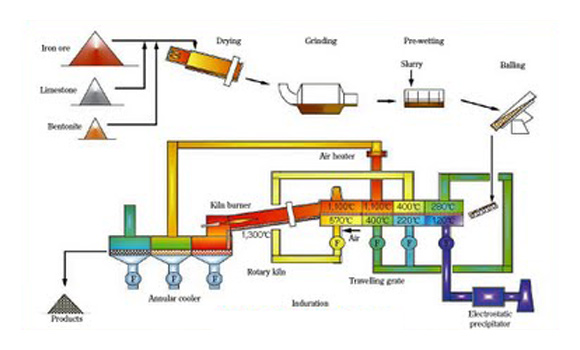

Stage 1: Raw Material Preparation

Iron ore concentrates entering the pellet plant typically contain 65-72% iron with varying amounts of silica, alumina, and other gangue minerals. The preparation stage ensures optimal particle size distribution usually 80% passing through 325 mesh (45 microns).

Grinding equipment reduces larger particles while maintaining the fine fraction needed for proper pellet formation. Ball mills and rod mills handle this size reduction efficiently, with classification systems ensuring consistent output particle sizes.

Moisture control begins at this stage. Raw materials may arrive too wet or too dry for optimal pellet processing. Drying equipment removes excess moisture, while controlled water addition brings material to target levels when needed.

Stage 2: Mixing and Conditioning

Uniform mixing represents a critical step in the iron pellet plant process. Bentonite clay, the primary binder, is added at 0.5-1.0% by weight. This natural clay mineral creates the adhesive forces needed for green pellet formation. Additional materials may include:

- Limestone or dolomite for basicity adjustment

- Coal dust or coke breeze as internal fuel

- Organic binders for improved green strength

- Flux materials for specific metallurgical requirements

High-intensity mixers ensure thorough blending within 2-3 minutes. Water sprays introduce moisture uniformly, bringing the mixture to 8-10% moisture content—the optimal range for pelletization. Insufficient mixing creates pellet quality variations, while over-mixing can break down the particle structure.

Stage 3: Pelletization – The Heart of the Pellet Process

The pellet process converts the prepared mixture into spherical green pellets through mechanical agglomeration using balling drum systems or disc pelletizer systems.

Balling Drum Systems use rotating cylindrical drums (8–12 RPM) with slight inclination to form pellets through tumbling action. They feature variable speed drives, automatic water spray systems, and adjustable slope for retention time control. Balling drums are ideal for high-capacity operations and produce uniform pellets with good size distribution.

Disc Pelletizer Systems use inclined rotating discs (45–52 degrees) where pellets grow through cascading action. They allow direct observation, quick parameter adjustment, lower capital investment, and compact installation, making them suitable for smaller capacities.

Both systems deliver quality pellets, with selection based on capacity requirements, space availability, and operational preferences.

Stage 4: Green Pellet Classification

Screening equipment separates green pellets by size immediately after formation. Multi-deck vibrating screens classify material into three fractions:

- Oversize pellets (>16mm): Crushed and recycled to balling equipment

- On-size pellets (8-16mm): Proceed to induration

- Undersize material (<8mm): Returns directly to balling equipment

This classification ensures uniform pellet sizes enter the induration system. Size consistency is crucial because smaller pellets heat faster than larger ones. Mixed sizes result in uneven thermal treatment some pellets over-fire while others remain inadequately processed.

Stage 5: Induration - Thermal Hardening in the Iron Ore Pelletizing Process

Induration represents the most technically demanding stage of the iron ore pelletizing process. Green pellets containing only binder-based strength undergo controlled high-temperature treatment that creates ceramic bonds, transforming them into hard, durable products.

Grate-Kiln Technology

This configuration combines traveling grate preheating with rotary kiln firing:

Zone 1 – Updraft Drying: Hot air (300-400°C) flows upward through the pellet bed on the traveling grate. Moisture evaporates gradually, preventing thermal shock that would crack pellets.

Zone 2 – Downdraft Preheating: Air flow reverses, heating pellets to 800-1000°C. Organic binders burn out, and magnetite begins oxidizing to hematite.

Zone 3 – Rotary Kiln Firing: Pellets transfer to a rotary kiln where temperatures reach 1250-1350°C. At these temperatures, solid-state reactions create ceramic bonds between particles. Hematite formation completes, and flux materials react with iron oxides.

Zone 4 – Controlled Cooling: Pellets return to the traveling grate for controlled cooling. Cooling equipment reduces temperature gradually, preventing thermal stress while recovering heat for process use.

Grate-kiln systems offer superior thermal efficiency through extensive heat recovery. Hot cooling air preheats combustion air, while exhaust gases dry incoming green pellets. This regenerative approach minimizes fuel consumption a major operating cost factor.

Straight Grate Technology

All induration stages occur on a single traveling grate system divided into functional zones:

- Updraft drying section

- Downdraft drying section

- Preheating with increasing temperature

- Firing zone with high-intensity burners

- Multiple stage cooling

Straight grate systems require higher fuel consumption compared to grate-kiln designs but offer lower capital investment and operational simplicity. They suit medium-capacity operations (1-3 MTPA) where simplicity outweighs energy efficiency concerns.

Stage 6: Product Cooling and Heat Recovery

Pellets leave the firing zone at 900–1100°C and are cooled to 100–150°C using cooling equipment with controlled air flow. The two main objectives are temperature reduction for safe handling and heat recovery for process reuse. Cooling air at 600–800°C is reused for combustion air preheating or steam generation, improving plant thermal efficiency. Controlled cooling increases compressive strength and reduces pellet damage.

Stage 7: Final Product Handling

Final screening systems remove damaged pellets. Material handling equipment such as belt conveyors, bucket elevators, and transfer chutes transport pellets with minimal breakage. Covered storage facilities prevent moisture absorption, and reclaim systems prepare pellets for dispatch.

Key Equipment Components of Our Pellet Plant

Primary Processing Equipment

- Balling Drums/Disc Pelletizers: Core pellet formation equipment

- Traveling Grate Systems: Multi-zone induration platform

- Rotary Kiln: High-temperature firing vessel

- Vibrating Screens: Size classification systems

Support Equipment Systems

- Mixing Equipment: High-intensity blenders for uniform preparation

- Crushing Systems: Oversize recycle processing

- Dust Collection: Bag house filters for environmental compliance

- Burner Systems: Multi-fuel firing capability

- Fan Systems: Induced draft and forced draft air handling

Automation and Control

- PLC/DCS Systems: Centralized process control

- Temperature Monitoring: Multiple zone temperature tracking

- Material Flow Control: Automated feed rate management

- Quality Monitoring: Automated sampling and testing

- Data Logging: Production tracking and analysis

Quality Parameters for Pellet Production

Successful pellet processing requires maintaining strict quality standards:

Green Pellet Properties

- Size distribution: 90% within 8-16mm range

- Drop number: 4-6 drops from 450mm height

- Compression strength: 800-1200 gm/pellet

- Moisture content: 8-10%

- Shape: Spherical with smooth surface

Fired Pellet Properties

- Compression strength: >250 kg/pellet

- Abrasion index: <5%

- Porosity: 18-25%

- Iron content: 62-67% Fe

- Chemical composition meeting customer specifications

- Reducibility index: >60%

- Tumble index: >90%

Laboratory testing equipment and automated sampling systems monitor these parameters continuously, ensuring consistent product quality.

Applications Beyond Iron Ore

While iron ore dominates pelletization applications, the technology extends to other materials:

Chrome Ore: Ferrochrome production feedstock requiring pelletization for improved furnace efficiency

Manganese Ore: Ferromanganese manufacturing benefits from pelletized material with better gas permeability

Nickel Laterite: RKEF process operations use laterite pellets for improved handling and reduction

Zinc/Lead Concentrates: Non-ferrous smelting operations agglomerate fines before pyrometallurgical treatment

Shalimar Engineering customizes equipment parameters to suit different material characteristics, addressing the unique challenges of each application.

Why Choose Shalimar Engineering as Your Manufacturer & Supplier

Comprehensive Manufacturing Capabilities

As a complete manufacturer and supplier, Shalimar Engineering ensures full control over pellet plant equipment production through:

- In-house design and engineering

- Advanced fabrication facilities

- ISO-certified quality management systems

- Factory testing, inspection, and complete documentation

Proven Technology and Experience

Our iron ore pelletizing plant solutions are backed by decades of industry experience and operate successfully across India and international markets, handling:

- Different ore mineralogy and chemistry

- Multiple capacity requirements

- Various fuel types and climate conditions

- Flexible automation levels

Turnkey Project Execution

We offer complete turnkey pellet plant solutions, including:

- Feasibility studies and process design

- Engineering and equipment supply

- Installation supervision and commissioning

- Performance testing, operator training, and after-sales support

- Spare parts supply and technical service

Energy-Efficient Design Philosophy

To reduce pellet plant operating costs, our designs integrate:

- Multi-stage heat recovery systems

- High-efficiency burners and optimized refractory design

- Variable speed drives for lower power consumption

- Advanced process control systems and waste heat utilization

Environmental Compliance

Our pelletizing plant designs meet strict environmental regulations with:

- High-efficiency dust collection systems (>99%)

- Continuous emission monitoring

- Water recycling and noise control systems

- Integrated waste handling solutions

Investment Considerations for Iron Ore Pelletizing Plant

We help clients optimize both capital investment and operating cost factors, including:

- Process and auxiliary equipment

- Civil works, electrical systems, and automation

- Fuel, power, maintenance, and labor costs

- Environmental compliance and quality control

Our engineering team ensures economical, reliable, and high-performance pellet plant solutions without compromising quality.

Get Started with Your Pelletizing Project

Whether planning a new pellet plant, expanding existing capacity, or modernizing aging equipment, Shalimar Engineering provides the expertise and equipment you need. Our manufacturer and supplier capabilities ensure quality, reliability, and performance throughout your project lifecycle.

Contact our technical team to discuss your specific requirements for an iron ore pelletizing plant. We’ll develop customized solutions matching your production goals, site conditions, and budget parameters.

Shalimar Engineering – Your Trusted Manufacturer & Supplier for Complete Pellet Plant Solutions

Frequently Asked Questions (FAQs)

A pellet plant converts iron ore fines into hard, spherical pellets through mixing, balling, screening, and high-temperature induration, making them suitable for blast furnaces.

Pellet plants typically range from 0.5 to 10 MTPA, with most medium-scale plants operating at 2–5 MTPA, depending on equipment size and process design.

Standard pellets have 8–16 mm size, >250 kg/pellet strength, 62–67% Fe, high tumble index, controlled basicity, and good reducibility.

Grate-kiln systems offer higher efficiency for large capacities, while straight grate systems are simpler and cost-effective for medium-scale plants.

Major costs include fuel, power, raw materials, and maintenance. Energy-efficient designs can reduce operating costs by 15–20%.

Enquiry and Purchase

Enquire now to receive a personalized proposal and optimize your pellet production.

Tags:- Iron Ore Pelletizing Plant Exporter in Bahrain, Iron Ore Pelletizing Plant Exporter in Iran, Iron Ore Pelletizing Plant Exporter in Iraq, Iron Ore Pelletizing Plant Exporter in Kuwait, Iron Ore Pelletizing Plant Exporter in Oman, Iron Ore Pelletizing Plant Exporter in Qatar, Iron Ore Pelletizing Plant Exporter in Saudi Arabia, Iron Ore Pelletizing Plant Exporter in Yemen, Continuous Iron Ore Pelletizing Plant Exporter in Bahrain, Continuous Iron Ore Pelletizing Plant Exporter in Iran, Continuous Iron Ore Pelletizing Plant Exporter in Iraq, Continuous Iron Ore Pelletizing Plant Exporter in Kuwait, Continuous Iron Ore Pelletizing Plant Exporter in Oman, Continuous Iron Ore Pelletizing Plant Exporter in Qatar, Continuous Iron Ore Pelletizing Plant Exporter in Saudi Arabia, Continuous Iron Ore Pelletizing Plant Exporter in Yemen, Batch Type Iron Ore Pelletizing Plant Manufacturer, Iron Ore Pelletizing Plant Manufacturer, Iron Ore Pelletizing Plant Manufacturer in Ahmedabad, Iron Ore Pelletizing Plant Manufacturer in India, Iron Ore Pelletizing Plant Exporter in India, Iron Ore Pelletizing Plant Exporter in Bangladesh, Iron Ore Pelletizing Plant Exporter in Bahrain, Iron Ore Pelletizing Plant Exporter in Hong Kong, Iron Ore Pelletizing Plant Exporter in Indonesia, Iron Ore Pelletizing Plant Exporter in Iran, Iron Ore Pelletizing Plant Exporter in Iraq, Iron Ore Pelletizing Plant Exporter in Israel, Iron Ore Pelletizing Plant Exporter in Jordan, Iron Ore Pelletizing Plant Exporter in Kuwait, Iron Ore Pelletizing Plant Exporter in Lebanon, Iron Ore Pelletizing Plant Exporter in Malaysia, Iron Ore Pelletizing Plant Exporter in Mongolia, Iron Ore Pelletizing Plant Exporter in Oman, Iron Ore Pelletizing Plant Exporter in Pakistan, Iron Ore Pelletizing Plant Exporter in Philippines, Iron Ore Pelletizing Plant Exporter in Qatar, Rotary Dryer Exporter in Saudi Arabia, Rotary Dryer Exporter in South Korea, Iron Ore Pelletizing Plant Exporter in Taiwan, Iron Ore Pelletizing Plant Exporter in Turkey, Iron Ore Pelletizing Plant Exporter in UAE, Iron Ore Pelletizing Plant Exporter in Vietnam.