Importance of Roller Crushers in Industrial Applications

In the world of industrial machinery, productivity, efficiency, and reliability depend heavily on the quality of the equipment being used. Among the wide range of machines employed for material processing, the roll crusher machine has established itself as an essential solution for industries like mining, cement, metallurgy, power generation, and recycling. These crushers simplify bulk material handling by reducing raw materials into manageable sizes, ensuring uniformity in production processes.

A roll crusher machine works by compressing material between two rotating cylinders, breaking it into smaller pieces. Though its mechanism appears simple, the performance of a roller crusher depends greatly on its design, material composition, and manufacturing quality. This is why choosing the right roller crusher manufacturer is critical. A trusted manufacturer does not merely provide equipment they deliver reliability, innovation, and long-term value to your industrial operations.

This article offers a comprehensive look into the factors you should evaluate when selecting a roller crusher manufacturer in Ahmedabad or elsewhere in India, while also discussing industry trends, benefits, and strategies to ensure your investment supports sustainable business growth.

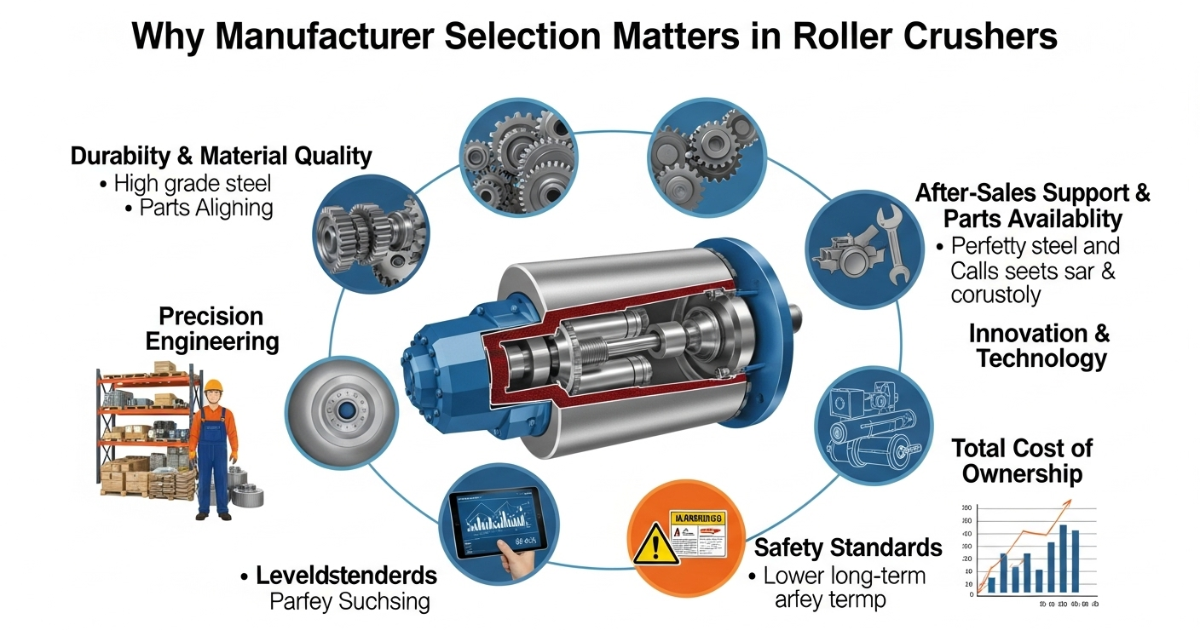

Why Manufacturer Selection Matters in Roller Crushers

The manufacturer plays a decisive role in determining the overall performance of roller crushers. A high-quality machine ensures durability, reduces operational downtime, and optimizes energy consumption. Conversely, poorly manufactured equipment from less reliable suppliers often results in frequent breakdowns, higher maintenance costs, and inconsistent product quality.

By partnering with a reputable roller crusher manufacturer, industries can benefit from:

- Enhanced durability: Machines built with high-strength alloys and precision engineering withstand demanding industrial conditions.

- Operational efficiency: Advanced roll crusher machines are designed for high throughput while minimizing energy consumption.

- Reliability: Consistent performance under heavy-duty operations ensures smoother production processes.

- Sustainability: Compliance with environmental standards and energy-efficient designs reduces operational costs.

- Comprehensive support: Access to spare parts, technical assistance, and service networks ensures minimal downtime.

Industrial Applications of Roller Crushers

The versatility of roll crusher machines makes them suitable for a wide range of industries:

- Mining and Minerals: Used to crush ores, stones, and metallic minerals before further processing.

- Cement Industry: Essential in breaking down limestone and clinker for cement production.

- Coal Industry: Applied in coal preparation plants to size coal for power generation.

- Recycling: Useful in reducing construction waste, broken glass, and other recyclable materials.

- Chemical Processing: Applied in crushing chemicals and raw minerals for further production.

Their ability to handle hard, abrasive, and brittle materials makes roll crusher machines indispensable in sectors where bulk raw material processing is essential.

Core Factors in Choosing a Roller Crusher Manufacturer

Industry Experience and Reputation

A manufacturer’s credibility is built over years of consistent service. Leading crusher manufacturers in India understand the complexities of different industrial sectors and produce machines designed to meet these challenges. Companies with long-standing experience reflect trust, technical expertise, and reliability in delivery.

Product Quality and Engineering Standards

The strength and life expectancy of a roll crusher machine depend on the quality of materials and engineering practices used by the manufacturer. Top roller crusher manufacturers in Ahmedabad and other industrial hubs use advanced metallurgy, including wear-resistant alloys and surface-hardened rollers, ensuring long-term durability. High engineering standards guarantee smooth operation, uniform output, and reduced maintenance costs.

Customization Capabilities

Every industry has unique material characteristics and production requirements. Reputable roller crusher manufacturers provide customized solutions, including variations in roller diameter, adjustable gap settings, or integration with automated systems. This customization ensures the roll crusher machine performs optimally and meets industry-specific operational needs.

Technological Advancements

Modern crusher manufacturers in India are adopting Industry 4.0 technologies to enhance machine performance. Features such as automation, smart sensors, predictive maintenance, and energy-efficient designs help industries reduce costs while maintaining consistent output. The integration of digital monitoring systems allows manufacturers to deliver roll crusher machines optimized for modern industrial workflows.

After-Sales Service and Support

Even high-quality equipment requires regular maintenance. A reliable roller crusher manufacturer in Ahmedabad provides timely technical assistance, spare parts availability, and maintenance support. Manufacturers with robust service networks ensure that industrial operations continue smoothly, minimizing downtime and production losses.

Cost and Value Balance

While upfront cost is important, industries should evaluate the total cost of ownership (TCO). Investing in a durable roll crusher machine from a reputable roller crusher manufacturer can save significant costs over the machine’s lifecycle, thanks to lower energy consumption, reduced maintenance, and longer operational life.

Safety and Environmental Compliance

Industrial processes face increasing scrutiny for safety and sustainability. Leading crusher manufacturers in India ensure their machines comply with international safety and environmental standards. Features such as dust suppression, noise reduction, and energy-efficient designs make modern roll crusher machines suitable for eco-conscious and future-focused operations.

Local vs. International Manufacturers

Industries often weigh the benefits of local versus international suppliers.

Local roller crusher manufacturers, especially in Ahmedabad, provide competitive pricing, faster customization, quicker delivery, and strong after-sales support. International suppliers may offer cutting-edge technologies but often come with higher costs, longer lead times, and potential delays in service.

For businesses operating in India, working with trusted crusher manufacturers in India ensures affordable machines, proximity for support, and faster access to spare parts. Gujarat, Maharashtra, and Tamil Nadu are key industrial hubs providing world-class roll crusher machines.

Strength of Indian Roller Crusher Manufacturers

India is emerging as a global leader in industrial machinery manufacturing. Roller crusher manufacturers in India are increasingly incorporating advanced designs, automation, and IoT-enabled solutions to meet global standards. Their strengths include:

- Competitive pricing that reduces capital investment

- Extensive spare parts availability and technical support

- Adoption of smart, energy-efficient roll crusher machines

- Compliance with international quality and safety standards

- Flexible and customized solutions for diverse industrial needs

These factors make Indian manufacturers highly attractive for both domestic and international buyers.

Common Mistakes Industries Make While Selecting Manufacturers

Poor decision-making in equipment selection can lead to setbacks. Common mistakes include:

- Focusing only on the lowest price instead of quality and durability

- Neglecting after-sales support and service networks

- Overlooking customization for specific operational requirements

- Ignoring safety and environmental compliance

- Failing to verify the manufacturer’s track record

By avoiding these errors, industries ensure that their investment in a roll crusher machine delivers consistent performance and long-term value.

Practical Approach to Selecting the Right Manufacturer

Industries should define operational requirements including material type, output size, and production capacity. Evaluation should then consider engineering quality, technology, customization, after-sales support, and TCO.

Site visits, case study reviews, and technical discussions with engineers from roller crusher manufacturers in Ahmedabad or other regions provide clarity. The final selection should prioritize long-term reliability and performance over initial cost.

Future Trends in Roller Crusher Manufacturing

Global trends are shaping the future of roll crusher machines:

- IoT-enabled monitoring systems for real-time operational analysis

- Predictive maintenance using AI to prevent downtime

- Multi-fuel compatibility for eco-friendly operations

- Advanced wear-resistant materials to extend machine lifespan

- Energy-efficient designs to reduce operating costs and carbon footprints

These innovations are positioning crusher manufacturers in India as leaders in global industrial machinery markets.

Conclusion

Selecting the right roller crusher manufacturer is a strategic decision impacting industrial efficiency, sustainability, and profitability. By focusing on quality engineering, customization, technological advancement, and robust after-sales support, industries can benefit from high-performance roll crusher machines that reduce costs and improve productivity.

With Indian manufacturers, particularly those in Ahmedabad, meeting global standards and offering competitive pricing, industries have access to world-class equipment that supports long-term growth and operational success.