How to Choose the Best Rotary Dryer Manufacturer for Your Industry

In the industrial sector, the efficiency of drying operations can significantly affect both product quality and operational costs. The Rotary Dryer has become a cornerstone in industries that handle minerals, chemicals, fertilizers, food products, and other bulk solids. Selecting a competent rotary dryer manufacturer is crucial to ensure the machine performs reliably, maintains consistent output, and operates efficiently over long periods.

India is home to a number of experienced rotary dryer manufacturers in India, particularly in Gujarat and Ahmedabad. These manufacturers offer machines tailored for diverse industrial requirements, combining advanced engineering, durable construction, and energy-efficient designs. Partnering with a reputable Rotary Dryer Manufacturer in Ahmedabad ensures that your equipment meets the demands of modern industrial operations, offering consistent drying performance while reducing operational challenges.

Understanding the Industrial Rotary Dryer

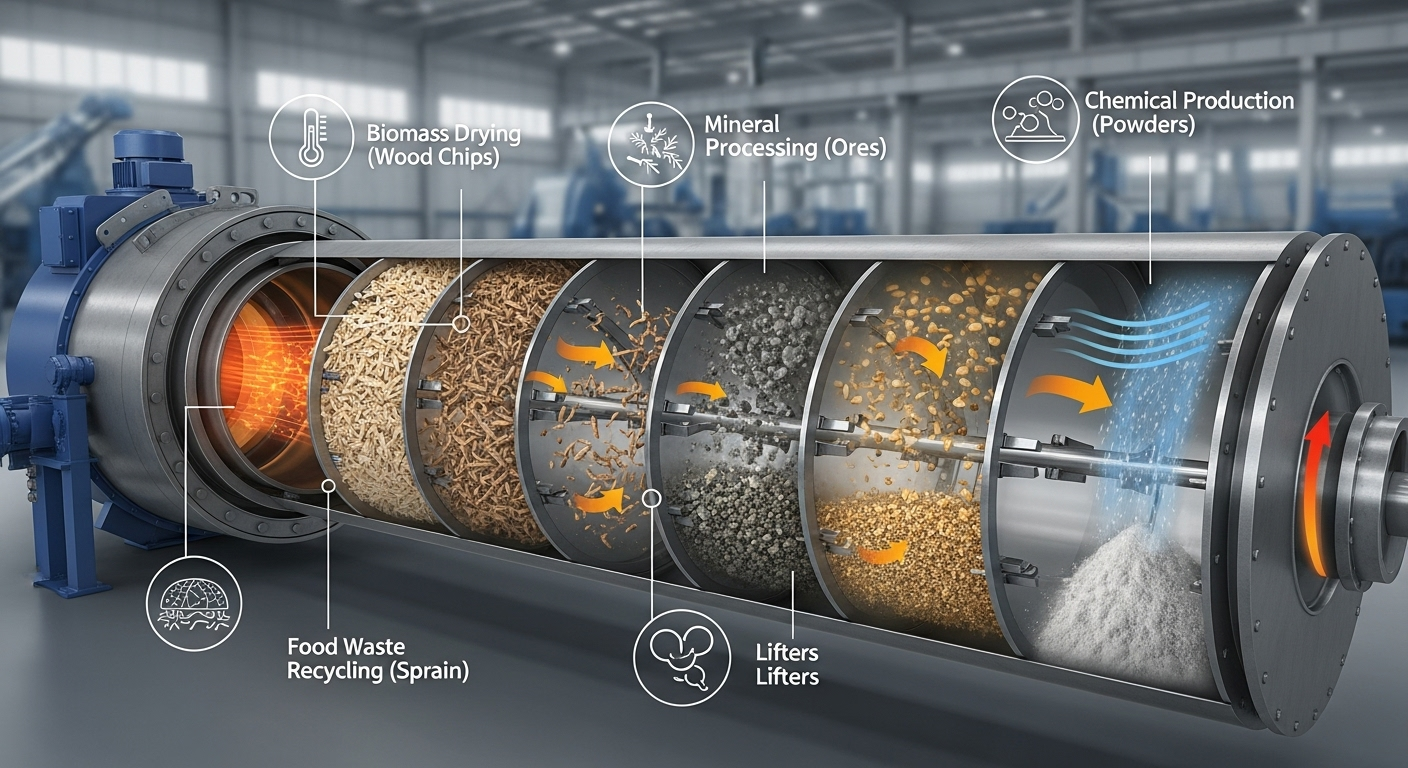

A Rotary Dryer is a rotating cylindrical machine that facilitates moisture reduction in bulk solids. The material enters the drum, where it is exposed to a flow of heated air or gases. The rotating motion ensures even exposure of the material to heat, promoting uniform drying. This process is essential for industries where precise moisture content directly impacts product quality, storage life, or subsequent processing steps.

Industrial sectors such as mineral processing, fertilizers, chemicals, and food benefit from Industrial Rotary Dryers because they provide controlled drying while maintaining product integrity. The efficiency of a dryer largely depends on its design, construction quality, and the expertise of the Rotary Dryer Manufacturer, which makes selecting the right supplier a key decision for operational success.

Why Choosing the Right Manufacturer Matters

Selecting an appropriate rotary dryer manufacturer goes beyond comparing prices. The quality of engineering, materials, and technical support directly impacts the machine’s efficiency, durability, and safety. Experienced manufacturers understand the challenges of industrial drying, such as handling different material properties, maintaining uniform moisture levels, and minimizing energy consumption.

A reliable Rotary Dryer Manufacturer in Ahmedabad can provide machines tailored to the specific requirements of your industry. Whether your operations demand high-volume continuous drying or precise batch processing, the manufacturer’s expertise ensures the equipment delivers consistent performance. Companies such as Shalimar Engineering are known for providing high-quality dryers designed to optimize industrial processes and meet stringent operational standards.

Material Quality and Construction

The durability and efficiency of a Rotary Dryer depend on the quality of materials used in its construction. Leading Rotary Dryer Manufacturers in Gujarat use high-grade steel for drums, wear-resistant liners, and robust bearings to withstand continuous operation and high temperatures. The design of the drum, including its length, diameter, and internal flighting, plays a critical role in ensuring even drying and reducing material degradation.

Manufacturers also emphasize precision in welding, alignment, and assembly, which helps prevent vibration, reduces maintenance requirements, and prolongs the machine’s operational life. By prioritizing material quality and engineering standards, trusted Rotary Dryer Suppliers deliver machines that maintain optimal performance even under challenging industrial conditions.

Efficiency and Performance Considerations

Industrial operations rely on drying equipment that balances speed, energy consumption, and product quality. Advanced Rotary Dryers incorporate features that enhance efficiency, such as optimized airflow patterns, precise rotational control, and uniform heat distribution. These elements allow industries to achieve consistent moisture levels in the final product, improving quality and reducing losses.

Energy efficiency is another critical factor. Manufacturers who design dryers with improved insulation, better heat transfer, and controlled exhaust systems help industries minimize operational costs. Selecting a reliable rotary dryer manufacturer ensures that your machine meets energy efficiency expectations without compromising performance, a factor particularly important for large-scale industrial operations.

Industrial Applications of Rotary Dryers

Rotary Dryers are versatile machines, used across multiple industrial sectors. In mineral processing, they prepare ores and industrial minerals for further processing, ensuring consistent particle size and moisture content. Fertilizer industries use these dryers to process chemical and organic fertilizers, achieving uniform moisture levels for storage and packaging.

In the food processing sector, Rotary Dryers handle grains, powders, and feed ingredients while maintaining product integrity. Similarly, chemical industries depend on these machines for drying heat-sensitive compounds without degradation. Even waste management and biomass processing industries rely on rotary dryers to reduce moisture content for easier handling, disposal, or reuse. Partnering with established Rotary Dryer Exporters ensures that your industrial requirements are met with machines capable of handling diverse materials efficiently.

Customization and Technical Support

One of the key factors in choosing a rotary dryer manufacturer in India is their ability to provide customized solutions. Industrial processes vary widely in terms of material characteristics, volume, and drying requirements. Manufacturers who offer tailored drum dimensions, flighting designs, and heating systems help optimize performance for specific industrial needs.

Equally important is the availability of technical support. Reputable Rotary Dryer Manufacturers in Ahmedabad provide guidance during installation, operation, and maintenance. Access to trained technicians, spare parts, and maintenance advice ensures minimal downtime and maximizes operational efficiency. Manufacturers such as Shalimar Engineering combine advanced technology with responsive support, ensuring that industrial operations run smoothly and efficiently.

Durability and Long-Term Reliability

The demanding nature of industrial drying requires equipment that can withstand continuous operation, abrasive materials, and varying temperatures. Trusted Rotary Dryer Suppliers focus on durability by using heavy-duty construction, wear-resistant liners, and high-quality mechanical components.

The reliability of a dryer also depends on proper engineering and assembly. Precision alignment of the drum, sturdy support structures, and high-grade bearings contribute to long-term stability and performance. Choosing an experienced rotary dryer manufacturer guarantees that the machine not only performs efficiently from day one but also maintains consistent output over years of operation.

Compliance and Industry Standards

Compliance with industrial standards is another important consideration. Leading Rotary Dryer Manufacturers in India ensure that their machines meet ISO and other relevant quality certifications. Compliance guarantees safety, operational efficiency, and consistent product quality. It also ensures that the dryer can be deployed in international projects without regulatory concerns, making trusted Rotary Dryer Exporters a preferred choice for global industrial clients.

Evaluating Manufacturer Reputation

Before selecting a rotary dryer manufacturer, it is important to evaluate their reputation and track record. Reviewing past projects, client testimonials, and case studies helps assess reliability, product quality, and service standards. Manufacturers with proven experience in delivering industrial rotary dryers across various sectors are more likely to provide machines that meet performance expectations.

Reputable Indian manufacturers, particularly those in Ahmedabad and Gujarat, are recognized for their technical expertise, adherence to quality standards, and responsive customer support. Working with such manufacturers ensures that industries receive durable, efficient, and high-performing Rotary Dryers.

Technological Advancements in Rotary Dryers

The industry is witnessing significant technological advancements in rotary drying. Manufacturers are integrating automated monitoring, real-time temperature control, and energy optimization systems into modern dryers. These features improve process control, reduce operational costs, and enhance safety.

Additionally, improvements in drum design, flighting configuration, and heat transfer efficiency allow dryers to handle a wider variety of materials, including heat-sensitive or abrasive substances. By partnering with forward-looking Rotary Dryer Manufacturers in India, industries can benefit from these innovations while ensuring their operations remain efficient and competitive.

Conclusion

Selecting the right rotary dryer manufacturer is essential for any industry seeking efficient, reliable, and durable drying solutions. With experienced Rotary Dryer Manufacturers in Gujarat and across India, industrial clients can access machines designed to meet specific operational requirements, maintain product quality, and optimize energy usage.

A trusted manufacturer not only provides a high-quality Industrial Rotary Dryer but also offers technical support, customization options, and long-term reliability. Companies such as Shalimar Engineering have established themselves as leading Rotary Dryer Suppliers, delivering machines that combine engineering excellence with operational efficiency.

Investing in a high-quality rotary dryer from a reputable manufacturer ensures that industrial drying operations are consistent, cost-effective, and sustainable. With the right partnership, industries can achieve optimal performance, reduce downtime, and maintain high standards in their production processes.

For more information or to get a quote, visit our Enquiry Page