Rotary Kiln Technology Trends and Innovations in Indian Manufacturing

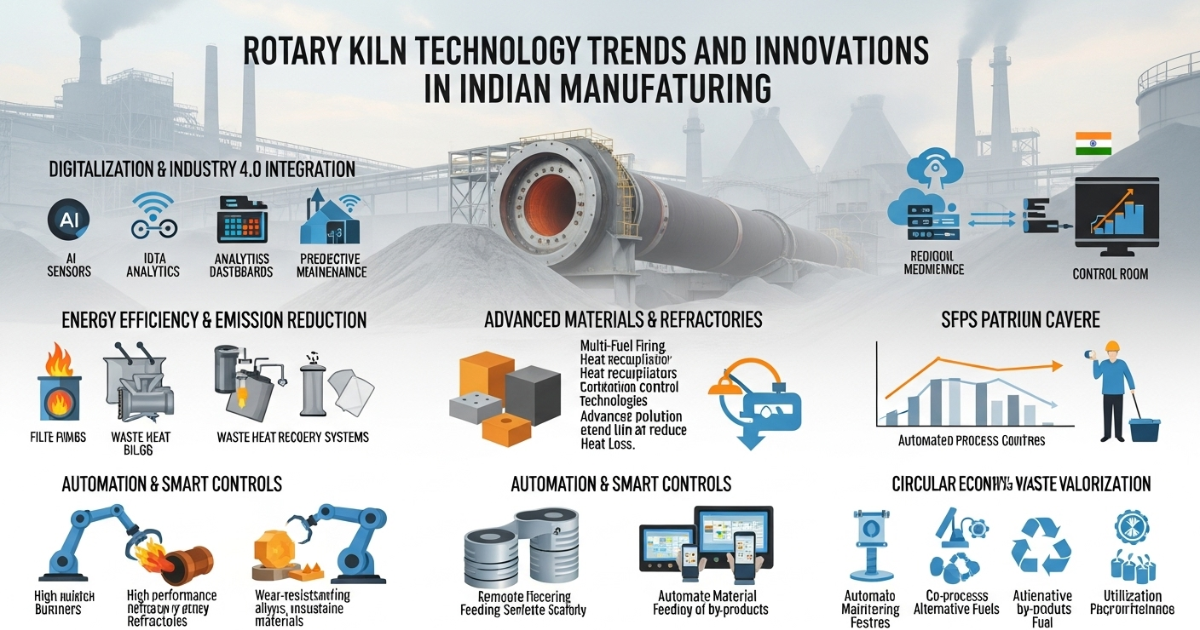

The Indian manufacturing landscape is witnessing a remarkable transformation, with rotary kiln technology at the forefront of industrial innovation. As the country emerges as a global manufacturing hub, rotary kiln manufacturers in India are pioneering cutting-edge technologies that revolutionize thermal processing across multiple industries. This evolution reflects India’s commitment to sustainable manufacturing and technological advancement.

The Digital Revolution in Rotary Kiln Operations

The integration of Industry 4.0 technologies has fundamentally changed how industrial rotary kilns operate in modern manufacturing facilities. Smart sensors, artificial intelligence, and machine learning algorithms are transforming traditional thermal processing into highly efficient, automated systems.

Advanced Process Control Systems

Modern rotary kiln manufacturers are incorporating sophisticated control systems that utilize real-time data analytics to optimize performance. These systems continuously monitor temperature profiles, gas composition, material flow rates, and energy consumption patterns. By analyzing this data, the control systems can automatically adjust operating parameters to maintain optimal conditions while minimizing energy consumption and emissions.

The implementation of predictive analytics enables operators to anticipate potential issues before they impact production. This proactive approach significantly reduces unplanned downtime and extends equipment life, making rotary kilns in India more reliable and cost-effective than ever before.

Internet of Things (IoT) Integration

IoT-enabled rotary kilns provide unprecedented visibility into operations through remote monitoring capabilities. Sensors throughout the kiln system collect data on vibration, temperature, pressure, and other critical parameters. This information is transmitted to centralized control rooms where engineers can monitor multiple installations simultaneously.

Rotary kiln suppliers in Gujarat are leading this technological adoption, offering IoT-integrated solutions that enable manufacturers to optimize operations across multiple facilities. This connectivity allows for centralized expertise and faster response times to operational challenges.

Energy Efficiency Innovations

Energy efficiency remains a critical focus for rotary kiln manufacturers in Gujarat, driven by both environmental concerns and operational cost considerations. Recent innovations in this area are delivering substantial improvements in fuel consumption and overall thermal efficiency.

Waste Heat Recovery Systems

Advanced waste heat recovery technologies are being integrated into modern industrial rotary kiln designs. These systems capture heat from exhaust gases and utilize it for preheating combustion air, raw materials, or generating steam for other processes. Some installations achieve energy recovery rates exceeding 80%, dramatically reducing overall fuel consumption.

Rotary kiln manufacturers in Ahmedabad have developed sophisticated heat exchanger designs that maximize recovery efficiency while minimizing maintenance requirements. These innovations are particularly valuable in energy-intensive industries like cement and steel production.

Alternative Fuel Technologies

The shift toward alternative fuels represents a significant trend in rotary kiln operations. Modern kilns are being designed to handle diverse fuel sources including biomass, waste-derived fuels, and hydrogen. This flexibility enables manufacturers to optimize fuel costs while reducing carbon footprints.

Multi-fuel burner systems developed by leading rotary kiln suppliers in India can seamlessly switch between different fuel types based on availability and cost considerations. This adaptability provides operational flexibility while supporting sustainability objectives.

Enhanced Insulation and Refractory Systems

Breakthrough developments in refractory materials and insulation systems are delivering significant energy savings. Advanced ceramic materials with superior thermal properties reduce heat losses while extending refractory life. These materials withstand higher temperatures and chemical attacks, reducing maintenance frequency and costs.

Modular refractory systems allow for targeted replacement of worn sections without shutting down the entire kiln, minimizing production losses during maintenance activities.

Environmental Technology Advancements

Environmental regulations and sustainability commitments are driving significant innovations in emission control and waste management technologies for rotary kilns.

Advanced Emission Control Systems

Next-generation emission control technologies are being integrated into modern rotary kiln designs to meet increasingly stringent environmental standards. These systems combine multiple treatment technologies including selective non-catalytic reduction (SNCR), fabric filters, and activated carbon injection to achieve ultra-low emission levels.

Rotary kiln manufacturers in India are developing cost-effective solutions that deliver superior environmental performance without compromising operational efficiency. These innovations position Indian manufacturers as leaders in sustainable industrial technology.

Carbon Capture and Utilization

Emerging carbon capture technologies are being piloted in rotary kiln applications, particularly in cement manufacturing. These systems capture CO2 from kiln exhaust gases for utilization in other industrial processes or permanent storage. While still in development stages, these technologies represent the future of low-carbon industrial processing.

Circular Economy Integration

Modern industrial rotary kilns are being designed to support circular economy principles by efficiently processing waste materials and byproducts. Co-processing capabilities enable kilns to handle municipal solid waste, industrial byproducts, and recycled materials while maintaining product quality standards.

Automation and Robotics Integration

The integration of advanced automation and robotics is transforming maintenance and operational procedures for rotary kilns in Gujarat and across India.

Automated Inspection Systems

Robotic inspection systems equipped with advanced imaging technologies can assess refractory condition, detect structural issues, and identify potential problems without requiring kiln shutdown. These systems provide detailed condition assessments that enable proactive maintenance planning.

Drone-based inspection technologies are being deployed for external kiln assessments, reducing safety risks and inspection time while providing comprehensive documentation of equipment condition.

Predictive Maintenance Technologies

Machine learning algorithms analyze operational data to predict component failure and optimize maintenance schedules. These systems can identify subtle changes in performance parameters that indicate developing issues, enabling timely intervention before failures occur.

Rotary kiln suppliers in Ahmedabad are incorporating these technologies into their service offerings, providing customers with comprehensive maintenance support that maximizes equipment availability and performance.

Material Handling and Processing Innovations

Advanced material handling systems are improving efficiency and reducing operational costs in rotary kiln operations.

Smart Feed Systems

Intelligent feed systems utilize advanced sensors and control algorithms to optimize material feeding rates and composition. These systems ensure consistent material flow while adapting to variations in raw material characteristics.

Real-time analysis of feed material enables automatic adjustments to maintain optimal kiln conditions, improving product quality and reducing energy consumption.

Advanced Clinker Cooling Technology

Innovative clinker cooling systems recover more waste heat while providing better temperature control. These systems utilize advanced heat transfer technologies to maximize energy recovery while ensuring proper clinker cooling for optimal cement quality.

Regional Innovation Hubs

India’s manufacturing regions are developing specialized expertise in rotary kiln technology, creating innovation ecosystems that drive continuous advancement.

Gujarat’s Technology Leadership

Gujarat has emerged as a leading center for rotary kiln innovation, with manufacturers in Ahmedabad and other industrial cities developing cutting-edge technologies. The state’s supportive industrial policies and infrastructure investments create an environment conducive to technological advancement.

Rotary kiln manufacturers in Gujarat benefit from proximity to research institutions, component suppliers, and skilled engineering talent. This ecosystem enables rapid innovation and technology transfer across the industry.

Collaborative Research and Development

Partnerships between rotary kiln manufacturers, research institutions, and end-users are accelerating technology development. These collaborations focus on addressing specific industry challenges while developing scalable solutions for broader market adoption.

Government initiatives supporting manufacturing innovation provide funding and incentives for technology development projects, further accelerating the pace of innovation in the sector.

Digitization of Manufacturing Processes

The digitization of manufacturing processes is revolutionizing how rotary kiln suppliers in India design, manufacture, and service their equipment.

Digital Twin Technology

Digital twin implementations create virtual replicas of physical kilns, enabling advanced simulation and optimization studies. These digital models help optimize operations, predict maintenance needs, and test operational changes before implementation.

Industrial rotary kiln operators can use digital twins to train personnel, optimize process parameters, and troubleshoot issues without impacting actual production operations.

Augmented Reality Applications

Augmented reality (AR) technologies are being deployed for maintenance training, troubleshooting, and remote assistance applications. Technicians can access detailed equipment information, maintenance procedures, and expert guidance through AR interfaces, improving efficiency and safety.

Quality Control and Testing Innovations

Advanced quality control technologies ensure consistent product quality while optimizing operational parameters.

Real-Time Process Monitoring

Continuous monitoring systems track product quality parameters in real-time, enabling immediate adjustments to maintain specifications. These systems utilize advanced analytical techniques including X-ray fluorescence, near-infrared spectroscopy, and particle size analysis.

Laboratory Automation

Automated laboratory systems reduce testing time and improve accuracy while providing comprehensive quality data for process optimization. These systems integrate with kiln control systems to enable closed-loop quality control.

Future Outlook and Emerging Technologies

The future of rotary kiln technology in Indian manufacturing promises continued innovation and advancement.

Artificial Intelligence Integration

AI applications are expanding beyond process control to include predictive maintenance, quality optimization, and energy management. Machine learning algorithms continue improving as they process larger datasets and gain operational experience.

Sustainable Technology Development

Ongoing research focuses on developing technologies that further reduce environmental impact while improving operational efficiency. This includes advanced materials, alternative energy sources, and innovative process configurations.

Modular and Flexible Designs

Future rotary kiln designs will emphasize modularity and flexibility, enabling rapid adaptation to changing market conditions and raw material characteristics. These designs will facilitate easier upgrades and modifications throughout the equipment lifecycle.

Implementation Strategies for Manufacturers

Successfully implementing these technological innovations requires strategic planning and systematic approaches.

Technology Assessment and Planning

Manufacturers should conduct comprehensive assessments of current operations to identify opportunities for technology implementation. This includes evaluating existing equipment capabilities, operational challenges, and improvement objectives.

Phased Implementation Approaches

Technology adoption should follow phased implementation strategies that minimize operational disruption while delivering measurable benefits. This approach enables learning and adaptation while building internal capabilities.

Training and Skill Development

Successful technology implementation requires comprehensive training programs that develop necessary skills and expertise within the organization. This includes technical training, operational procedures, and maintenance practices.

Conclusion

The technological transformation of rotary kiln manufacturing in India represents a significant leap forward in industrial capability and competitiveness. These innovations are positioning Indian manufacturers as global leaders in thermal processing technology while supporting the country’s manufacturing growth objectives.