How Rotary Dryers Work: Principle, Process, and Applications

Rotary Dryer Fundamentals

In industrial processes, moisture control is one of the most crucial factors for ensuring quality and efficiency. Industries ranging from mining and minerals to chemicals, agriculture, and food processing rely on drying technologies to deliver consistent results. Among the various drying equipment available today, the Rotary Dryer is considered one of the most reliable and versatile solutions.

As a leading Rotary Dryer Manufacturer in India, Shalimar Engineering specializes in designing and supplying energy-efficient dryers tailored to meet industry-specific needs. With years of experience and innovation in engineering, Shalimar Engineering has become a trusted name not only in India but also across international markets.

In this blog, we’ll explore in detail how rotary dryers work, their principle, process, applications, and why choosing the right rotary dryer manufacturer is critical for industrial success.

What is a Rotary Dryer?

A Rotary Dryer is a large, rotating cylindrical drum used for drying bulk solids. It works on the principle of direct or indirect heating, where hot gases or air flow through the cylinder, reducing the moisture content of materials.

Rotary dryers are widely used in industries because:

- They can handle a wide variety of materials.

- They are cost-effective and energy-efficient.

- They deliver uniform and consistent drying results.

These dryers are highly flexible and can be customized in size, material of construction, and heating source, depending on the application.

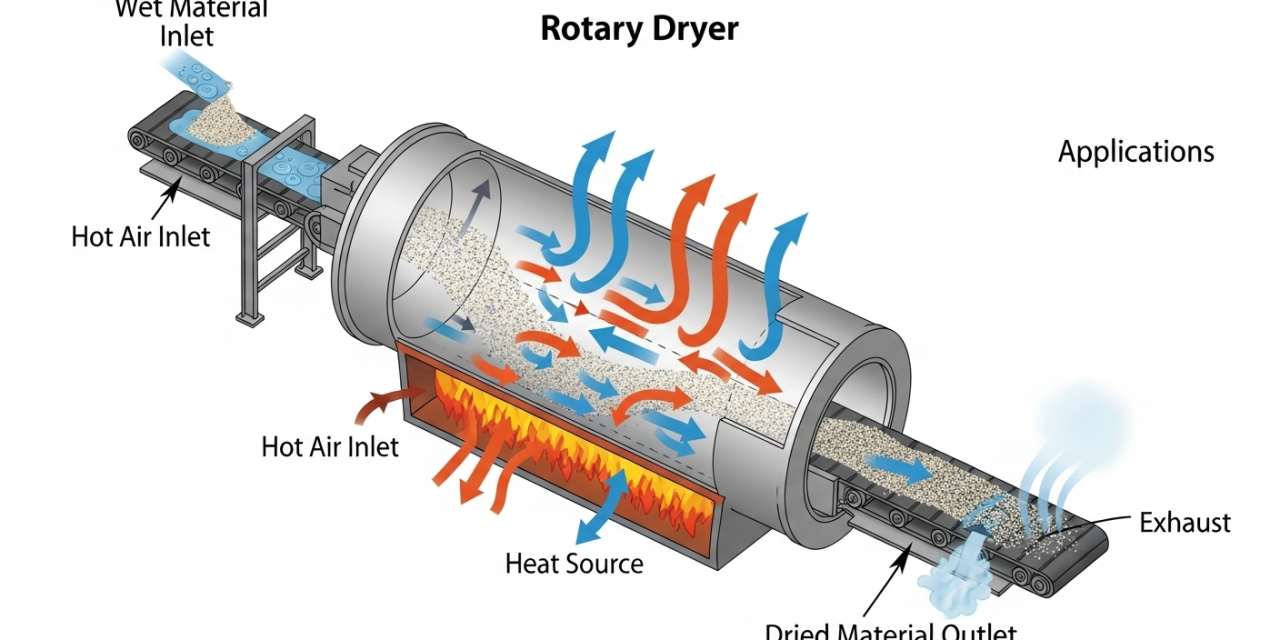

Working Principle of a Rotary Dryer

The working principle of a rotary dryer is simple yet highly effective. It combines heat transfer with material movement inside the rotating drum.

Key Steps in the Drying Process:

- Feeding the Material – Wet or moisture-laden material is fed into the rotating drum from one end using conveyors or feeders.

- Hot Gas Supply – Hot air or gas is introduced into the drum, either co-currently (same direction as material flow) or counter-currently (opposite direction).

- Material Lifting & Cascading – Inside the drum, lifters continuously lift and drop the material, ensuring maximum surface exposure to the hot gases.

- Moisture Evaporation – As the material travels through the drum, moisture evaporates gradually due to heat transfer.

- Discharge – The dried material exits from the other end of the drum, ready for further processing or packaging.

This combination of rotation, lifting, and heating ensures efficient drying even for materials with varying particle sizes and moisture levels.

Types of Rotary Dryers

Rotary dryers can be classified based on design and heating method:

- Direct Rotary Dryer – Hot gases directly contact the material. Suitable for minerals, ores, and fertilizers.

- Indirect Rotary Dryer – Heat is supplied through the dryer shell without direct contact. Best for chemicals, food, and fine powders.

- Co-Current Flow Dryers – Material and hot gases move in the same direction. Ideal for materials sensitive to overheating.

- Counter-Current Flow Dryers – Material and gases move in opposite directions, ensuring better heat transfer and lower final moisture.

Advantages of Rotary Dryers

- High Efficiency – Uniform drying due to material cascading.

- Versatility – Handles a wide range of bulk solids.

- Scalability – Available for small, medium, and large-scale operations.

- Durability – Built to withstand high temperatures and continuous operations.

- Energy Savings – Modern designs minimize energy consumption.

As a trusted Rotary Dryer Manufacturer in Ahmedabad, Shalimar Engineering ensures that each dryer is optimized for efficiency and durability.

Industrial Applications of Rotary Dryers

Rotary dryers are widely used across industries due to their adaptability. Some common applications include:

1. Mineral Industry

- Drying ores, limestone, sand, and clay.

- Prepares raw materials for further processing.

2. Chemical Industry

- Drying powders, salts, fertilizers, and catalysts.

- Ensures product consistency and quality.

3. Agriculture & Food Industry

- Drying grains, seeds, sugar, and biomass.

- Prevents spoilage and extends shelf life.

4. Cement & Construction Materials

- Used for drying cement slurry, fly ash, and aggregates.

5. Fertilizer Industry

- Efficient drying of urea, ammonium nitrate, and phosphates.

6. Energy & Biomass

- Drying wood chips, sawdust, and biofuels for energy production.

Why Choose Shalimar Engineering as Your Rotary Dryer Manufacturer?

When selecting a rotary dryer manufacturer in India, it is crucial to consider experience, engineering quality, and after-sales service. Shalimar Engineering stands out due to the following factors:

- Customized Solutions – Each rotary dryer is designed to suit the client’s specific material and capacity requirements.

- Quality Assurance – Stringent testing ensures long-lasting performance.

- Turnkey Support – From design and supply to installation and commissioning.

- Global Reach – Recognized as one of the leading rotary dryer exporters serving industries worldwide.

- Energy Efficiency – Advanced designs ensure reduced power and fuel consumption.

Whether you need an industrial rotary dryer or a specialized solution for chemical and mineral processing, Shalimar Engineering delivers reliable equipment tailored to your needs.

Key Features of Shalimar Engineering Rotary Dryers

- Robust design with high-quality steel.

- Precision-engineered lifters for efficient material movement.

- Energy-saving systems with optimized heat transfer.

- Low maintenance requirements.

- Scalable for future expansion.

These features make Shalimar Engineering one of the most trusted rotary dryer manufacturers in Gujarat and across India.

Choosing the Right Rotary Dryer Manufacturer in India

Before investing in a rotary dryer, industries should evaluate:

- Experience of the Manufacturer

- Quality of Materials Used

- Energy Efficiency of Design

- Customization Options

- After-Sales Support

Shalimar Engineering fulfills all these requirements, making it a preferred choice for industries seeking long-term drying solutions.

Future of Rotary Dryers in India

With growing industrialization, demand for efficient drying solutions is expected to rise significantly. Industries such as steel, cement, fertilizers, and biomass energy will continue to rely on rotary dryers for consistent and reliable performance.

As sustainability becomes a priority, Shalimar Engineering is also investing in eco-friendly designs and energy-efficient solutions to meet global environmental standards.

Frequently Asked Questions (FAQs)

Q1: What industries use rotary dryers the most?

A1: Rotary dryers are widely used in minerals, chemicals, fertilizers, cement, agriculture, and biomass industries.

Q2: How does a rotary dryer differ from a fluid bed dryer?

A2: Rotary dryers handle larger particle sizes and higher moisture levels, while fluid bed dryers are best for fine powders.

Q3: Can rotary dryers be customized for specific materials?

A3: Yes, Shalimar Engineering designs customized rotary dryers to suit material properties and production requirements.

Q4: What is the lifespan of a rotary dryer?

A4: With proper maintenance, a high-quality rotary dryer can last for 15–20 years or more.

Q5: Why choose Shalimar Engineering over other manufacturers?

A5: With decades of experience, advanced engineering, and turnkey project support, Shalimar Engineering is a trusted name in India and abroad.

Conclusion

Rotary dryers have become indispensable in modern industries due to their efficiency, versatility, and reliability. From minerals and fertilizers to biomass and chemicals, they provide a robust solution for drying bulk solids at scale.

As one of the leading Rotary Dryer Manufacturers in India, Shalimar Engineering offers world-class equipment backed by engineering excellence and customer-centric services. Whether you require a rotary dryer manufacturer in Ahmedabad, rotary dryer suppliers in Gujarat, or rotary dryer exporters for global projects, Shalimar Engineering is your trusted partner.

With a commitment to quality, innovation, and sustainability, Shalimar Engineering ensures that every dryer delivers long-term performance, reduced costs, and maximum efficiency.

Contact Shalimar Engineering Today to discuss your rotary dryer requirements and get a tailored solution for your industry.