Biggest Manufacturer and Supplier of Ball Mills in India

India has emerged as a leading center for industrial machinery production, with the Ball Mill standing as one of the most crucial machines in the grinding and material processing sector. Used across industries like cement, minerals, ceramics, paints, and chemicals, a Ball Mill Machine plays an essential role in achieving uniform grinding and mixing results.

The growing need for energy-efficient and reliable grinding systems has fueled the rise of reputed Ball Mill Manufacturers in India. Among them, Shalimar Engineering has established itself as a trusted Ball Mill Manufacturer and Supplier, offering engineered solutions that deliver consistent results across industries.

What is a Ball Mill and Why It’s Important

A Ball Mill is an industrial grinder used for fine pulverization and blending of materials. It consists of a rotating cylindrical shell partially filled with grinding media such as steel or ceramic balls. As the mill rotates, the motion of the balls crushes and grinds the raw materials into fine powder.

The design and performance of a Ball Mill Machine make it suitable for both wet and dry grinding operations. Industries prefer this equipment for its high grinding efficiency, uniform product size, and versatility across a wide range of materials including cement clinker, ores, pigments, and ceramics.

Selecting the right Ball Mill Manufacturer ensures the equipment’s longevity, energy efficiency, and consistent output. Industrial clients rely on Indian suppliers for their precision engineering, cost-effectiveness, and strong after-sales support.

Evolution of Ball Mill Manufacturing in India

The evolution of Ball Mill Manufacturing in India mirrors the nation’s industrial progress. Over the last few decades, the country has become a preferred destination for heavy equipment design, machining, and fabrication. This success is driven by technological innovation, skilled manpower, and a focus on quality control.

Today, Ball Mill Manufacturers in India produce equipment that matches global standards in terms of performance, durability, and operational efficiency. From small laboratory mills to large continuous plants, Indian companies cater to the full range of industrial requirements.

Shalimar Engineering, for instance, has been instrumental in developing cost-effective solutions for grinding and mixing applications. Its range of Ball Mill Machines is designed to meet the demanding needs of industries that require precision, reliability, and energy optimization.

Construction and Working Principle of a Ball Mill Machine

A Ball Mill Machine is designed to perform continuous or batch grinding using a rotating cylindrical shell. The shell is typically made from mild or alloy steel and is mounted on bearings for smooth operation. Grinding media commonly known as ball mill balls fill a part of the shell.

When the mill rotates, the balls impact and grind the material due to friction and centrifugal force. The rotation speed, ball size, and charge volume are carefully optimized to achieve the desired fineness.

Key components include:

- Rotating Shell: The main grinding chamber.

- Trunnions & Bearings: Support rotation and reduce friction.

- Liners: Protect the inner surface from wear.

- Gear Drive: Transfers power from the motor to the mill.

This proven design makes the Ball Mill highly efficient for crushing, mixing, and grinding solid materials under various industrial conditions.

Types of Ball Mills Manufactured in India

India’s top Ball Mill Manufacturers and Ball Mill Suppliers produce various types to serve different operational needs:

- Batch Type Ball Mill: Designed for small or controlled production volumes, allowing complete control over each grinding cycle.

- Continuous Ball Mill: Used for large-scale production where materials flow continuously through the mill for higher throughput.

- Wet Grinding Ball Mill: Preferred for materials requiring moisture or slurry consistency.

- Dry Grinding Ball Mill: Used in cement, chemical, and mineral industries for dry powder applications.

- Laboratory Ball Mill: Compact and efficient models for research and quality testing.

Each design offered by Indian Ball Mill Machine Manufacturers focuses on maximizing grinding efficiency, energy conservation, and operational safety.

Role of Material Selection in Ball Mill Manufacturing

The quality and durability of a Ball Mill Machine depend heavily on the materials used in its construction. Leading Ball Mill Manufacturers in India select components that provide strength, wear resistance, and long-term stability.

- Shell Material: Usually made of high-grade steel or alloy steel to withstand high stress and temperature.

- Liners: Fabricated from manganese steel, rubber, or ceramic materials to minimize abrasion.

- Grinding Media: The Ball Mill Balls Suppliers provide media of various densities and sizes steel, alloy, or ceramic depending on the application.

- Bearings & Gears: Heavy-duty, precision-engineered parts to ensure smooth operation and extended lifespan.

This careful material selection ensures the Ball Mill operates efficiently even under continuous industrial workloads.

Quality and Standards Maintained by Indian Ball Mill Manufacturers

One of the major strengths of Ball Mill Manufacturers in Ahmedabad and other parts of India is their commitment to quality. Companies such as Shalimar Engineering follow strict manufacturing standards and quality inspection systems.

Testing procedures typically include:

- Non-destructive testing for weld joints

- Dimensional accuracy verification

- Load and performance testing under actual conditions

- Balancing and alignment checks

Adherence to international standards like ISO and ASTM helps Indian Ball Mill Suppliers deliver globally accepted products that maintain consistent performance and reliability.

Importance of a Reliable Ball Mill Supplier

Industrial plants depend on continuous operation, and downtime can result in significant losses. Partnering with a dependable Ball Mill Supplier ensures the availability of spare parts, technical support, and timely maintenance.

A professional supplier provides:

- On-site installation and commissioning

- Operator training

- Spare part supply including liners, bearings, and ball mill balls

- Regular maintenance and service contracts

Shalimar Engineering, as a reputed Ball Mill Supplier in India, offers comprehensive support throughout the equipment’s lifecycle. Its technical service team ensures optimal performance and minimal operational interruptions, helping industries maintain steady production.

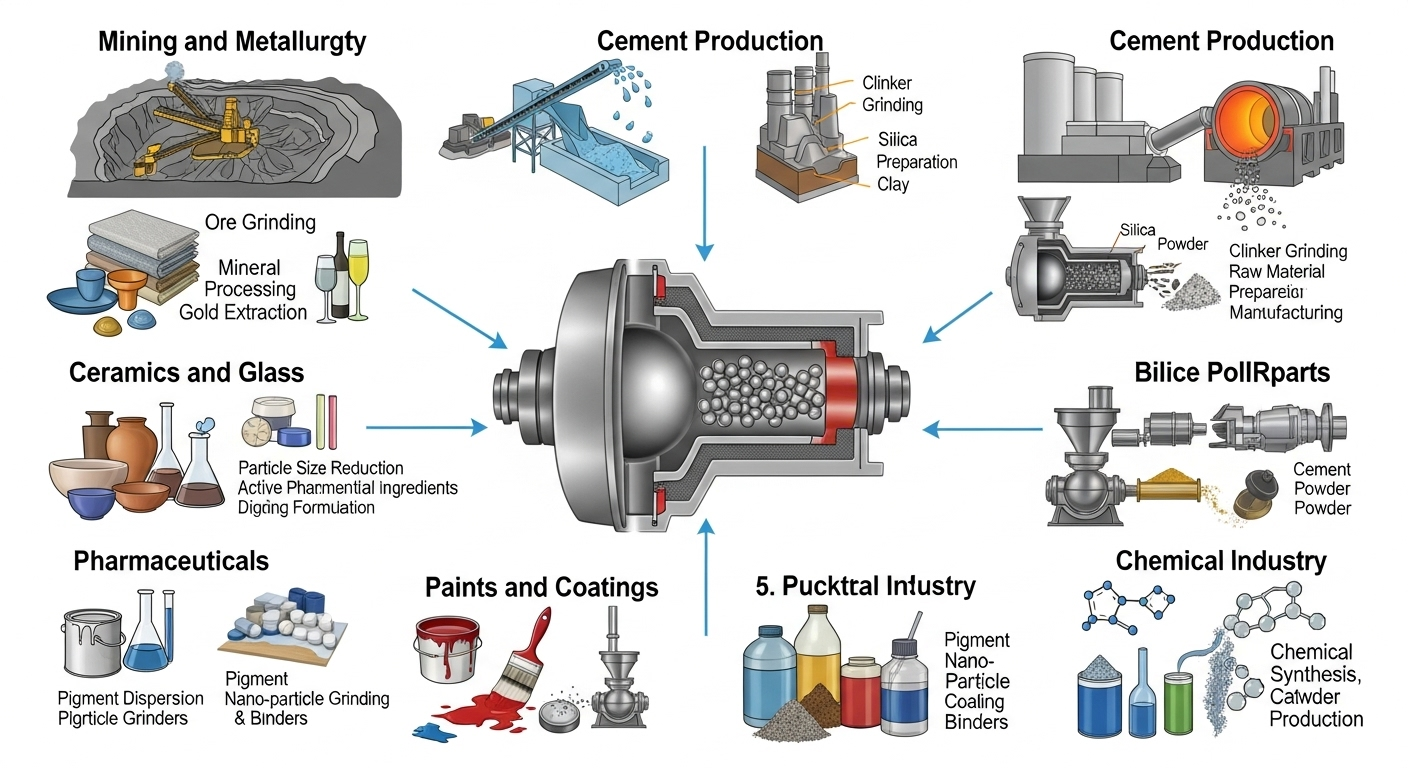

Applications of Ball Mills in Various Industries

The versatility of Ball Mill Machines makes them an essential part of numerous industries.

- Cement Industry: For grinding clinker and additives into fine cement powder.

- Mining & Mineral Processing: For crushing and refining ores.

- Ceramic Industry: For homogenizing raw clay and glaze materials.

- Chemical Industry: For processing powders, catalysts, and pigments.

- Paints & Pigments: For dispersing solid pigments into uniform suspensions.

- Pharmaceutical Industry: For blending and micronizing raw ingredients.

These applications underline the significance of choosing the right Ball Mill Manufacturer in India who understands specific industry requirements and provides tailored design and engineering solutions.

Why Indian Manufacturers Lead the Global Ball Mill Market

The competitive edge of Ball Mill Manufacturers in India lies in their combination of engineering excellence, affordability, and customization. Indian companies produce mills comparable to European or American designs at significantly lower production costs.

The reasons behind this success include:

- Modern manufacturing facilities equipped with CNC and robotic systems.

- Deep understanding of material processing industries.

- Skilled engineers with decades of experience in mill design.

- Integration of energy-saving technologies.

- Consistent after-sales support and service assurance.

Shalimar Engineering, for example, has gained global recognition as an innovative Ball Mill Manufacturer that integrates technology, craftsmanship, and reliability into every product.

The Relationship Between Ball Mill Efficiency and Grinding Media

The efficiency of a Ball Mill Machine largely depends on the properties of its grinding media. The type, size, and hardness of the ball mill balls directly influence energy consumption and final particle size.

Choosing the correct grinding media can result in:

- Reduced grinding time

- Improved fineness and uniformity

- Lower wear on liners and shell

- Better power utilization

Leading Ball Mill Balls Suppliers in India provide customized media solutions based on specific material characteristics and grinding requirements. Collaboration between the mill manufacturer and the media supplier ensures consistent performance and cost efficiency.

Advantages of Buying from Indian Ball Mill Manufacturers

Opting for an Indian Ball Mill Manufacturer offers tangible advantages for domestic and international buyers alike:

- Competitive Pricing: Lower production costs due to local sourcing and skilled labor.

- Quick Delivery: Reduced lead times compared to imported equipment.

- Custom Engineering: Design flexibility to meet unique industrial challenges.

- Robust Construction: Machines built to withstand continuous industrial use.

- After-Sales Support: Easy access to maintenance and spare parts.

These benefits make Ball Mill Manufacturers in Ahmedabad and across India a trusted choice for both local and global industries seeking dependable grinding solutions.

Future Outlook of Ball Mill Manufacturing in India

With India’s industrial growth and the “Make in India” initiative, the future of Ball Mill Manufacturing looks highly promising. Manufacturers are increasingly investing in automation, digital monitoring, and eco-friendly designs to reduce power consumption and emissions.

The next generation of Ball Mill Machines will integrate intelligent controls, real-time performance tracking, and modular configurations for easy maintenance. As industries transition toward sustainable production, energy-efficient ball mills will play a vital role in reducing operational costs.

Companies like Shalimar Engineering are at the forefront of this technological shift, consistently upgrading designs and adopting innovative manufacturing methods to meet the evolving demands of the market.

Conclusion

India stands among the world’s top destinations for high-quality industrial grinding equipment. The country’s expertise in mechanical design, metallurgy, and process engineering has positioned it as a powerhouse for Ball Mill Manufacturing.

For industries seeking reliability, precision, and long-term performance, choosing a trusted Ball Mill Manufacturer and Ball Mill Supplier ensures smooth operations and high productivity.

Brands such as Shalimar Engineering continue to represent the excellence and innovation that define India’s engineering capabilities delivering efficient, durable, and cost-effective Ball Mill Machines that power the nation’s growth in cement, mining, and chemical sectors.

For more information or to get a quote, visit our Enquiry Page