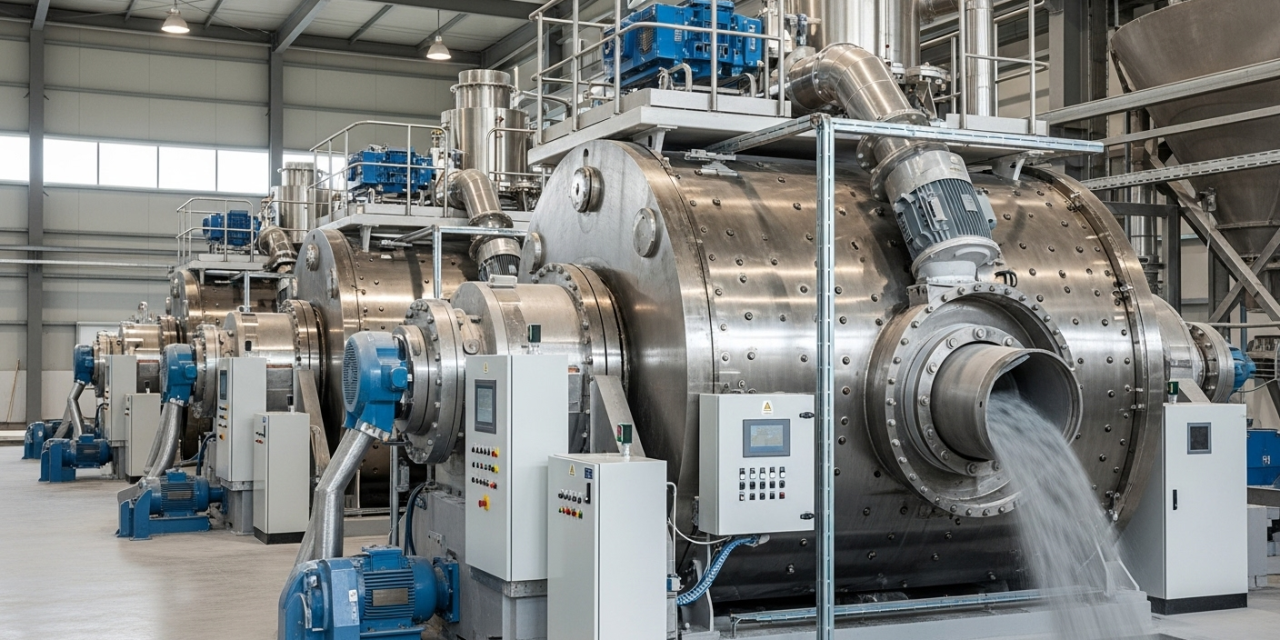

Advanced Technology Ball Mills for Mineral Applications

In the mineral processing industry, efficient and precise grinding is critical for both productivity and product quality. Grinding determines particle size, surface area, and the uniformity of materials, all of which influence downstream processes such as beneficiation, flotation, and chemical extraction. The Ball Mill Machine has emerged as one of the most essential tools for achieving these outcomes, enabling industries to process ores, minerals, and chemical compounds effectively.

India has established itself as a global hub for industrial machinery manufacturing, with specialized Ball Mill Manufacturers in India producing high-quality, durable, and technologically advanced grinding equipment. Companies like Shalimar Engineering have earned recognition as reliable Ball Mill Manufacturers and Suppliers, delivering machines that combine precision engineering with robust construction and energy efficiency.

Understanding Ball Mills and Their Importance

A Ball Mill is a cylindrical device that rotates around a horizontal axis, partially filled with grinding media such as steel, ceramic, or rubber balls. As the cylinder rotates, the balls tumble and crush the material, reducing it to a fine powder. The process is critical in industries where particle size uniformity and efficiency are key, including cement, mining, chemical, and ceramic industries.

The performance of a Ball Mill Machine depends on various factors, including the rotational speed, size and type of grinding media, mill diameter, and material properties. Selecting a reputable Ball Mill Manufacturer ensures that these factors are optimized for maximum efficiency, durability, and reliability.

Advanced Features in Modern Ball Mill Machines

Modern Ball Mill Machines incorporate cutting-edge features to improve efficiency and operational reliability. Some of the key innovations include:

- Optimized Grinding Media Movement: Advanced designs ensure uniform ball motion, increasing grinding efficiency and reducing wear.

- Variable Speed Drives: Allows fine-tuning of rotation speed based on material characteristics, improving precision and consistency.

- Automated Monitoring Systems: Digital sensors track vibration, load, and speed, ensuring optimal operation while minimizing downtime.

- High-Durability Liners and Shells: Use of manganese steel, alloy steel, or ceramic liners reduces wear and extends service life.

- Energy Efficiency: Incorporation of energy-saving motors and optimized grinding mechanisms reduces operational costs.

These features allow modern Ball Mill Machines to perform effectively under demanding industrial conditions, handling both soft and hard mineral ores with precision.

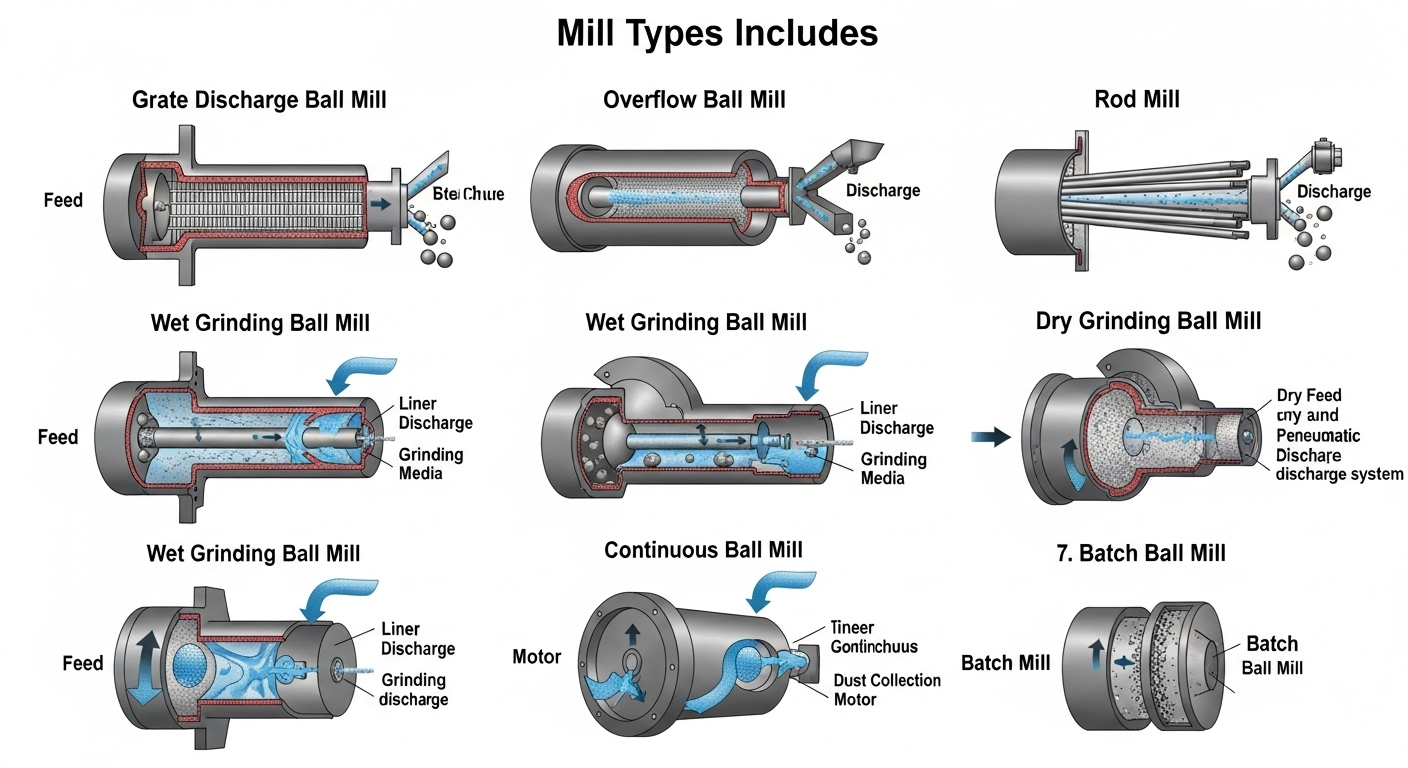

Types of Ball Mills for Mineral Applications

Indian manufacturers offer various types of Ball Mill Machines tailored for mineral applications:

- Continuous Ball Mills: Ideal for large-scale processing plants that require uninterrupted operation.

- Batch Ball Mills: Suitable for smaller operations or applications needing controlled grinding cycles.

- Wet Grinding Ball Mills: Efficient for ores that need to be processed in slurry form, improving particle size distribution.

- Dry Grinding Ball Mills: Commonly used in cement and chemical industries where moisture-free grinding is required.

- Laboratory Ball Mills: Compact mills used for testing, research, and small-batch production.

By offering such diverse options, Ball Mill Manufacturers in Ahmedabad and across India ensure that industrial clients can choose the right machine based on their specific mineral and process requirements. Shalimar Engineering, for instance, provides customized solutions to meet precise operational needs while maintaining reliability and efficiency.

Material Selection in Ball Mill Manufacturing

The materials used in a Ball Mill Machine significantly influence its performance and longevity. Leading Ball Mill Manufacturers in India prioritize material quality to produce mills capable of enduring continuous industrial operations:

- Shell Material: High-grade alloy steel or mild steel with proper heat treatment ensures resistance to wear and high mechanical stress.

- Liners: Made from manganese steel, ceramic, or rubber, liners protect the mill shell and enhance grinding efficiency.

- Grinding Media: High-quality ball mill balls with specific sizes and densities are supplied by reliable Ball Mill Balls Suppliers to ensure uniform grinding.

- Bearings and Gears: Precision-engineered components reduce friction, improve load handling, and extend machine life.

Material selection is crucial to ensuring that the Ball Mill Machine maintains optimal performance, reduces maintenance costs, and achieves consistent output even under challenging operational conditions.

Applications of Ball Mills in Mineral Industries

Advanced Ball Mill Machines are widely used in mineral processing for several applications:

- Iron Ore Grinding: Achieves fine particle size for pelletizing, beneficiation, and chemical processing.

- Copper and Zinc Processing: Ensures uniform particle distribution for flotation and extraction.

- Gold and Silver Ore Milling: Provides precise grinding for optimal recovery rates.

- Bauxite and Alumina Processing: Produces fine powders required for chemical and metallurgical applications.

- Industrial Minerals: Efficient grinding of talc, limestone, barite, and other minerals for various industrial purposes.

The ability to handle diverse mineral properties makes modern Ball Mill Machines an indispensable component in mining and mineral processing operations.

Advantages of Advanced Technology Ball Mills

Selecting high-quality Ball Mill Machines from reputed Ball Mill Manufacturers in India offers numerous benefits:

- High Grinding Efficiency: Optimized ball motion and advanced engineering reduce energy consumption.

- Precision and Consistency: Automated monitoring ensures uniform particle size and material quality.

- Durable and Long-lasting: Superior materials and construction reduce wear and maintenance requirements.

- Flexible Designs: Machines can be customized for mineral type, process scale, and grinding requirements.

- Energy Savings: Reduced power consumption through optimized motor and grinding designs.

These advantages make Indian Ball Mill Manufacturers globally competitive, providing machines that meet both domestic and international standards. Shalimar Engineering, as a leading Ball Mill Supplier, ensures that its clients receive reliable, high-performance machines optimized for mineral applications.

Quality Standards and Manufacturing Process

Quality assurance is a defining factor for Indian Ball Mill Manufacturers in Ahmedabad. Companies like Shalimar Engineering adhere to strict quality protocols at every stage of production:

- Engineering and Design: Precision calculations ensure optimal grinding and reduced energy consumption.

- Material Procurement: Use of certified high-grade steel, liners, and bearings for durability.

- Assembly and Testing: Machines are carefully assembled and tested under simulated industrial conditions to ensure performance and reliability.

- Inspection and Certification: Compliance with ISO and ASTM standards guarantees consistent quality.

Such rigorous quality control ensures that Ball Mill Machines operate efficiently for extended periods, with minimal downtime and maintenance requirements.

Role of Grinding Media

The performance of a Ball Mill Machine is closely linked to the grinding media used. The ball mill balls are designed to:

- Transfer energy efficiently during grinding

- Minimize wear on liners and shells

- Ensure uniform particle size

- Improve throughput and process efficiency

Reliable Ball Mill Balls Suppliers provide media tailored to the specific mineral type, hardness, and desired output. Collaboration between the Ball Mill Manufacturer and media suppliers is essential for achieving optimal results and maintaining consistent product quality.

Energy Efficiency and Environmental Considerations

Modern Ball Mill Machines are designed not only for performance but also for energy efficiency. By reducing power consumption and improving grinding efficiency, these mills help mineral processing plants reduce operational costs while minimizing environmental impact.

- Optimized Designs: Reduce friction and improve ball motion for lower energy use.

- Variable Speed Drives: Allow mills to operate at optimal speeds depending on material type.

- Sustainable Materials: Use of wear-resistant liners and eco-friendly grinding media reduces material wastage.

These features position Indian Ball Mill Manufacturers as environmentally responsible suppliers, aligning with global sustainability goals.

Future Trends in Ball Mill Technology

The next generation of Ball Mill Machines will integrate advanced automation, digital monitoring, and modular design:

- Smart Mills: Real-time monitoring of load, vibration, and temperature for precise control.

- Automation: Reduced manual intervention, improving safety and operational efficiency.

- Energy-efficient Designs: Further reductions in power consumption through optimized engineering.

- Modular Construction: Simplifies maintenance, repair, and installation.

Manufacturers like Shalimar Engineering are leading the way, providing technologically advanced solutions for mineral processing plants that meet modern industry standards and sustainability requirements.

Conclusion

Advanced Ball Mill Machines have become indispensable in mineral processing, offering precise grinding, consistent performance, and energy efficiency. Choosing a reputable Ball Mill Manufacturer and Ball Mill Supplier, such as Shalimar Engineering, ensures access to durable, high-performance equipment tailored to specific industrial requirements.

With Indian manufacturers leading in engineering innovation, quality, and cost-effectiveness, industries benefit from reliable machines that support high productivity, reduce operational costs, and maintain product quality. For mineral processing operations, investing in an advanced Ball Mill Machine is a strategic step toward efficiency, precision, and sustainable growth.

For more information or to get a quote, visit our Enquiry Page