Introduction

Industrial grinding operations form the backbone of numerous manufacturing processes across India and globally. Among various grinding equipment available, a ball mill remains the most reliable and widely used machine for material size reduction. Whether you’re processing cement, minerals, pharmaceuticals, or ceramics, understanding the intricacies of grinding equipment and selecting the right ball mill manufacturer can significantly impact your production efficiency and bottom line.

This comprehensive guide provides detailed insights into ball mill technology, applications, types, selection criteria, and pricing considerations. As industries continue to demand higher precision and efficiency, partnering with an experienced ball mill supplier becomes crucial for operational success.

Understanding Ball Mill Technology

A ball mill operates on a simple yet effective principle of size reduction through impact and attrition. The cylindrical shell, partially filled with grinding media (steel, ceramic, or rubber balls), rotates around its horizontal axis. As the cylinder rotates, the grinding balls cascade and tumble, crushing the material fed into the mill.

The grinding process occurs in three distinct ways:

Impact: Grinding balls drop from the top of the mill shell, striking the material with force and breaking larger particles.

Attrition: As balls slide and roll against each other and the mill wall, they grind material trapped between them through friction.

Abrasion: The continuous tumbling action creates surface contact that gradually wears down material particles.

The rotation speed, ball charge volume, and material feed rate all influence the grinding efficiency. Optimal settings vary based on material hardness, desired fineness, and throughput requirements. Modern mills incorporate advanced control systems that maintain consistent parameters for uniform product quality.

Types of Ball Mills and Their Specifications

Selecting the appropriate ball mill configuration depends on your specific processing requirements. Here are the main types available:

Overflow Ball Mills

Overflow designs discharge ground material through the outlet trunnion when the mill is filled beyond capacity. This simple discharge mechanism makes overflow mills suitable for fine grinding applications. The material residence time is longer, producing finer particle sizes. Industries processing materials that require extreme fineness, such as paint pigments and certain mineral concentrates, prefer overflow configurations.

The overflow ball mill operates at lower rotation speeds compared to other types, typically 65-75% of critical speed. This slower rotation creates a cascading action rather than cataracting, which is ideal for achieving ultra-fine particle distribution.

Grate Discharge Ball Mills

Grate mills feature a perforated plate at the discharge end that controls particle size output. Only material ground to the desired fineness passes through the grate openings, preventing over-grinding and improving efficiency. The forced discharge mechanism reduces material retention time, increasing throughput capacity.

Mining operations processing metallic ores extensively use grate discharge mills. The design prevents accumulation of fine particles, maintaining consistent grinding conditions. Grate mills operate at higher speeds (75-80% of critical speed), creating a cataracting action that increases impact forces.

Tube Mills

Tube mills represent an elongated version of standard ball mills, with length-to-diameter ratios exceeding 3:1. The extended length provides multiple grinding zones, each potentially containing different ball sizes for progressive size reduction. This multi-stage grinding within a single unit produces very fine products efficiently.

Cement industries use tube mills extensively for clinker grinding. The compartmentalized design allows coarse grinding in the first chamber and fine grinding in subsequent chambers. Some tube mills reach lengths of 15 meters or more for large-scale production.

Vertical Ball Mills

Vertical configurations rotate around a vertical axis, utilizing gravity to assist the grinding process. The compact footprint makes vertical mills suitable for facilities with space constraints. Material feeds from the top, and ground product discharges from the bottom through a screen or classifier.

Chemical and pharmaceutical manufacturers favor vertical ball mills for batch processing. The design allows easy cleaning between batches, preventing cross-contamination. Vertical mills also offer better heat dissipation, important for temperature-sensitive materials.

Planetary Ball Mills

Laboratory-scale planetary mills feature multiple grinding jars mounted on a rotating platform. The jars rotate on their own axes while revolving around the platform center, creating high-energy impact conditions. These mills achieve extremely fine grinding and are used for research, development, and small-scale production.

Industrial Applications of Ball Mills

The versatility of grinding technology makes ball mills indispensable across diverse sectors:

Cement Manufacturing

The cement industry represents the largest consumer of industrial grinding equipment. Ball mills grind cement clinker mixed with gypsum to produce various cement types. The fineness of cement directly affects strength development and setting time, making grinding quality critical.

Modern cement plants operate continuous grinding circuits with separator systems that return coarse particles for regrinding. Shalimar Engineering designs cement ball mills that handle capacities from 50 TPH to 500 TPH, meeting diverse production scales.

Mining and Mineral Processing

Ore processing facilities use ball mills to liberate valuable minerals from host rock. Gold, copper, iron, and other metallic ore concentrators depend on efficient grinding for successful downstream separation. The grinding circuit often accounts for 50% of total processing costs, making equipment efficiency crucial.

Different ore types require specific grinding approaches. Hard, abrasive ores need robust mill construction with wear-resistant liners. Softer ores may use ceramic balls to prevent iron contamination in the final concentrate.

Pharmaceutical Industry

Pharmaceutical manufacturing requires precise particle size control for drug formulation and bioavailability. Ball mills grind active pharmaceutical ingredients (APIs) and excipients to specified fineness. The pharmaceutical sector demands equipment constructed from stainless steel or specialized alloys to meet stringent hygiene standards.

Batch processing with thorough cleaning between product changes prevents cross-contamination. Many pharmaceutical ball mills operate under controlled atmospheres (nitrogen or argon) when processing oxygen-sensitive compounds.

Ceramics Production

Ceramic manufacturing involves grinding raw materials like clay, feldspar, quartz, and kaolin into fine slurries or powders. The particle size distribution affects ceramic properties including strength, porosity, and surface finish. Wet grinding in ball mills produces uniform slurries for casting or spray drying.

Ceramic industry ball mills often use alumina or porcelain balls and liners to prevent iron contamination that would discolor white ceramics. The grinding process must achieve specific rheological properties in the slurry for proper forming.

Paints and Coatings

Paint manufacturers use ball mills to disperse pigments and additives into liquid binders. The grinding action breaks pigment agglomerates and distributes particles uniformly throughout the vehicle. Color development, gloss, and coating performance depend on proper pigment dispersion.

Horizontal media mills and basket mills (variations of ball mill technology) are common in paint production. The choice between wet and dry grinding depends on the formulation requirements.

Chemical Processing

Chemical industries grind various compounds for reactions, catalysts, and final products. Specialty chemicals often require specific particle size distributions to achieve desired reaction rates or product characteristics. Grinding under inert atmospheres prevents oxidation or unwanted reactions.

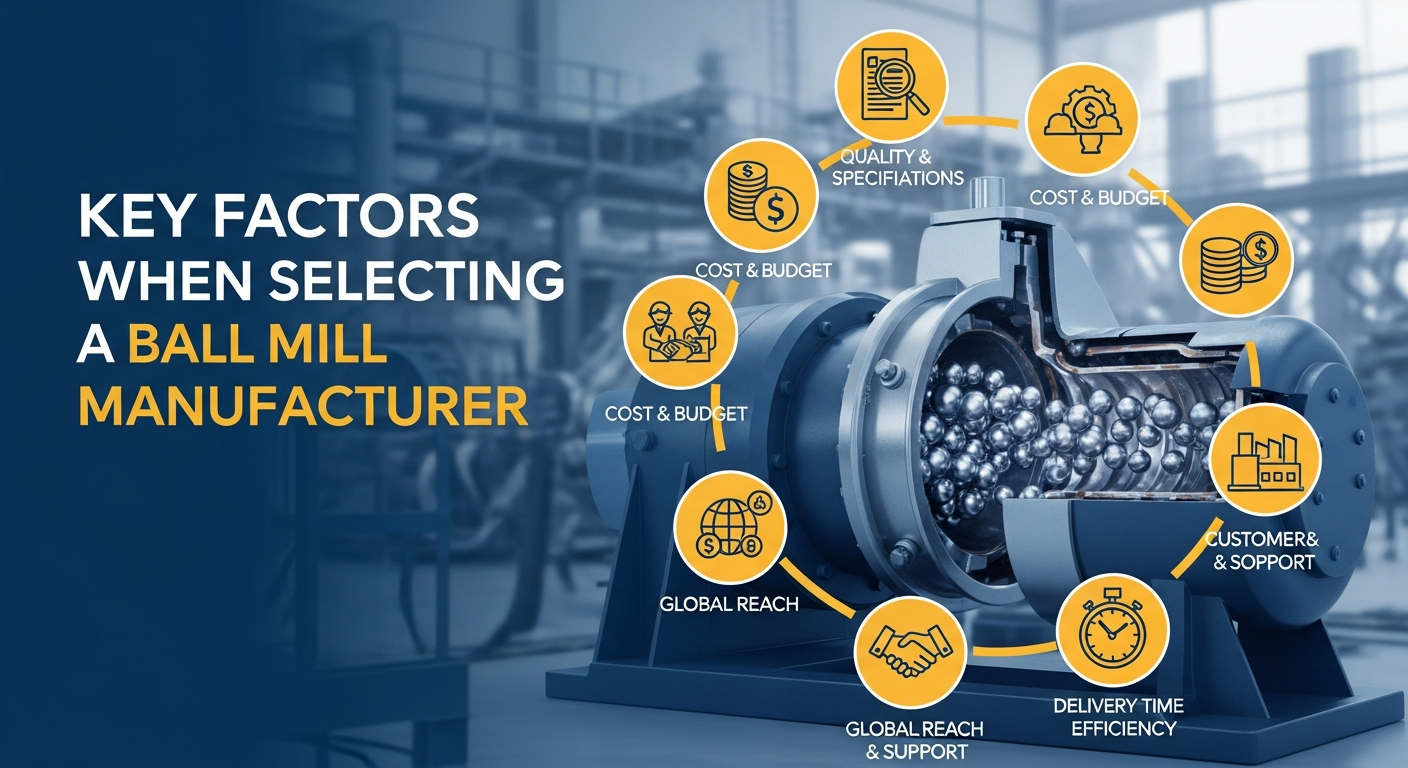

Key Factors When Selecting a Ball Mill Manufacturer

Choosing the right ball mill manufacturer influences equipment performance, reliability, and lifecycle costs:

Manufacturing Experience and Expertise

A manufacturer with substantial industry experience understands the nuances of grinding technology. Shalimar Engineering has manufactured industrial equipment for years, accumulating knowledge about material behavior, wear patterns, and operational challenges across various industries.

Experienced manufacturers anticipate potential issues during design, incorporating features that prevent common problems. They also provide valuable consultation regarding mill sizing, material selection, and process optimization.

Quality Standards and Certifications

Quality manufacturing ensures equipment longevity and consistent performance. Look for manufacturers following ISO 9001 quality management systems. Proper quality control includes material testing, dimensional verification, welding inspection, and performance testing before delivery.

Reputable ball mill manufacturers source components from certified suppliers and maintain traceability for critical parts. Documentation including material test certificates, fabrication records, and quality inspection reports accompanies equipment delivery.

Customization Capabilities

Every grinding application has unique requirements regarding capacity, material characteristics, and product specifications. The ability to customize mill dimensions, drive systems, liner materials, and discharge arrangements ensures optimal performance.

Shalimar Engineering offers customized ball mill designs tailored to client specifications. Whether you need special alloy construction for corrosive materials, explosion-proof motors for combustible products, or integrated classification systems, customization capabilities matter.

Technical Support and Service

Equipment installation, commissioning, and ongoing maintenance require technical expertise. A reliable ball mill supplier provides comprehensive support including:

- Site assessment and foundation design guidance

- Installation supervision and commissioning

- Operator training on proper operation and maintenance

- Troubleshooting support for operational issues

- Spare parts availability with quick delivery

- Periodic inspection and preventive maintenance services

Post-sale support often determines the total cost of ownership more than the initial purchase price.

Innovation and Technology Integration

Modern grinding plants incorporate automation, process control, and energy efficiency features. Manufacturers investing in research and development offer advanced solutions like:

- Variable frequency drives for optimal rotation speed control

- Automated lubrication systems reducing manual intervention

- Real-time monitoring of bearing temperature, vibration, and power consumption

- Process control integration with plant DCS/SCADA systems

- Energy-efficient designs reducing power consumption per ton of material ground

Ball Mill Pricing Factors and Considerations

Understanding pricing components helps in budgeting and comparing quotations from different ball mill manufacturers:

Size and Capacity

Mill capacity is the primary pricing determinant. Small laboratory mills (0.5-5 kg capacity) cost a few lakhs, while industrial mills (50-500 TPH) range from tens of lakhs to several crores. The cylindrical shell diameter and length determine capacity, with larger dimensions requiring more material and fabrication effort.

Materials of Construction

Standard mild steel construction offers the lowest cost but suits only non-corrosive, non-abrasive materials. Stainless steel construction costs 2-3 times more than mild steel but provides corrosion resistance for chemical and pharmaceutical applications. Specialized alloys for highly corrosive environments command premium prices.

Liner materials also affect costs. Rubber liners are economical but wear faster in highly abrasive applications. Manganese steel or chromium alloy liners cost more but last significantly longer with abrasive materials.

Drive System Components

The motor, gear reducer, and coupling system represent significant cost components. Larger mills require higher horsepower motors and heavy-duty reducers. Variable frequency drives add cost but provide operational flexibility and energy savings.

Premium manufacturers use reputable brands for drive components, ensuring reliability. Lower-priced quotations sometimes include inferior motors or gears that fail prematurely.

Accessories and Auxiliary Equipment

Complete grinding systems include more than just the ball mill:

- Feed conveyors or feeders

- Discharge systems (elevators, conveyors, air slides)

- Classifiers or separators for closed-circuit grinding

- Dust collection systems

- Control panels and instrumentation

- Cooling water systems for bearing lubrication

Including these auxiliaries in the initial quotation provides accurate project costs and ensures compatible components.

Installation and Commissioning

Some ball mill suppliers quote FOB (Free on Board) prices excluding installation, while others provide turnkey solutions. Installation costs include foundation preparation, equipment erection, piping, electrical connections, and commissioning. Turnkey quotations simplify project execution but may cost more upfront.

Obtaining Accurate Quotations

To receive precise pricing from Shalimar Engineering or other manufacturers, provide:

- Material characteristics (hardness, abrasiveness, moisture content)

- Feed size and desired product fineness

- Required capacity (tons per hour)

- Operating mode (continuous or batch)

- Special requirements (corrosion resistance, explosion-proof, cleanability)

- Site conditions (space constraints, power availability)

Detailed specifications enable manufacturers to recommend optimal configurations and provide accurate pricing.

Installation and Operational Considerations

Proper installation and operation maximize ball mill performance and lifespan:

Foundation Requirements

Heavy rotating equipment needs robust foundations to handle static loads, dynamic forces, and vibrations. The foundation must be perfectly level and properly cured before equipment installation. Inadequate foundations cause misalignment, excessive vibration, and premature bearing failure.

Alignment and Assembly

Precise alignment of the mill shell, trunnions, bearings, and drive system is critical. Misalignment causes uneven load distribution, increased wear, and higher power consumption. Professional installation teams use laser alignment tools to achieve specified tolerances.

Grinding Media Selection

Ball size, material, and charge volume significantly affect grinding efficiency. Smaller balls produce finer products but grind slower. Larger balls handle coarse feed better but may not achieve required fineness. Many operations use graded ball charges with larger balls in the feed end and smaller balls toward the discharge.

Ball materials include:

- Forged or cast steel (most common, economical)

- High-chrome alloy (abrasion-resistant, longer life)

- Ceramic or porcelain (prevents contamination in ceramics and pharmaceuticals)

- Rubber-coated steel (for soft materials)

Maintenance Protocols

Regular maintenance extends equipment life and prevents unexpected downtime:

Daily checks: Bearing temperature, unusual noises, vibration levels, power consumption

Weekly maintenance: Lubrication inspection and replenishment, bolt tightness verification

Monthly inspections: Liner wear assessment, grinding media top-up, coupling alignment check

Annual shutdowns: Liner replacement, comprehensive bearing inspection, gear oil change, structural integrity assessment

Predictive maintenance using vibration analysis and thermography identifies developing problems before failures occur.

Why Choose Shalimar Engineering as Your Ball Mill Supplier

Shalimar Engineering stands out as a trusted ball mill manufacturer in India for several reasons:

Proven Track Record: Years of manufacturing experience across diverse industries demonstrates capability and reliability.

Quality Manufacturing: Adherence to quality standards ensures durable equipment that performs consistently over extended periods.

Custom Engineering: Tailored solutions address specific grinding challenges, ensuring optimal results for your application.

Competitive Pricing: Direct manufacturer pricing without intermediary markups provides value without compromising quality.

Comprehensive Support: From initial consultation through installation, commissioning, and ongoing maintenance, Shalimar Engineering supports clients throughout the equipment lifecycle.

Client-Focused Approach: Understanding client requirements and providing honest recommendations builds long-term partnerships rather than one-time sales.

Conclusion

Selecting the appropriate ball mill and partnering with the right ball mill manufacturer are critical decisions that impact production efficiency, product quality, and operational costs. Understanding mill types, applications, selection criteria, and pricing factors enables informed decision-making.

Whether your operation requires grinding cement clinker, processing metallic ores, manufacturing pharmaceuticals, or producing ceramics, working with an experienced ball mill supplier like Shalimar Engineering ensures you receive equipment designed for your specific needs. Quality manufacturing, custom engineering, and comprehensive support translate into reliable performance and favorable economics over the equipment’s operational life.

Get started with India’s trusted ball mill manufacturer today!