Introduction

Material processing industries worldwide depend on efficient grinding equipment to transform raw materials into usable products. Understanding what a Ball mill is and how it functions remains essential for anyone involved in manufacturing, mining, pharmaceuticals, or chemical processing. This cylindrical grinding machine has revolutionized industrial material processing since its invention, offering reliable size reduction for countless applications.

This comprehensive guide explains ball mill fundamentals, working mechanisms, various types available, critical applications, and factors to consider when selecting equipment from trusted manufacturers. Whether you’re planning new installations or upgrading existing facilities, understanding these machines ensures informed decision-making that impacts production efficiency and profitability.

Get Expert Ball Mill Consultation →

What Is a Ball Mill? Definition and Overview

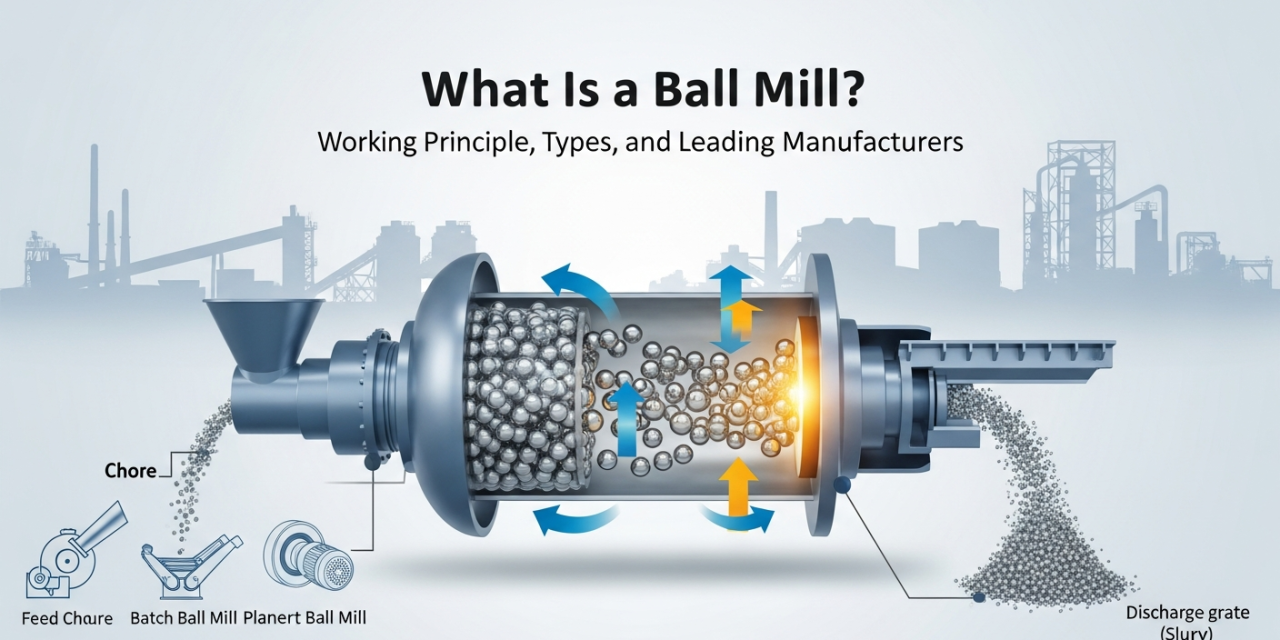

A ball mill is a cylindrical grinding device used to reduce material particle size through mechanical force. The machine consists of a hollow cylindrical shell rotating around its horizontal axis, partially filled with grinding media typically steel, ceramic, or rubber balls. As the cylinder rotates, the grinding media cascades, tumbles, and impacts the material, progressively reducing particle size until the desired fineness is achieved.

These grinding machines range from small laboratory units processing grams of material to massive industrial installations handling hundreds of tons per hour. Despite size variations, all ball mills operate on the same fundamental principles of impact, attrition, and abrasion.

The versatility of ball mills makes them indispensable across industries including:

- Cement manufacturing for clinker grinding

- Mining operations for ore processing

- Pharmaceutical production for API particle size control

- Ceramic industries for raw material preparation

- Chemical processing for compound size reduction

- Paint manufacturing for pigment dispersion

Industrial ball mills represent significant capital investments, making proper understanding of their operation, capabilities, and selection criteria crucial for businesses.

Ball Mill Working Principle: How Does It Function?

Understanding the ball mill working principle helps optimize operations and troubleshoot performance issues. The grinding process involves several mechanisms working simultaneously:

Rotation and Critical Speed

The cylindrical shell rotates around its horizontal axis at a controlled speed. The rotation speed, expressed as a percentage of critical speed, significantly affects grinding efficiency. Critical speed is the theoretical rotation rate at which grinding media would centrifuge against the mill wall without cascading.

Industrial ball mills typically operate at 65-80% of critical speed. Lower speeds (65-70%) create cascading action where grinding media tumbles from the top of the charge, ideal for fine grinding. Higher speeds (75-80%) produce cataracting action where media is thrown across the mill, providing greater impact forces suitable for coarser grinding.

Grinding Mechanisms

Three primary mechanisms reduce particle size inside a ball mill:

Impact Grinding: As the mill rotates, grinding balls lift along the rising side of the mill shell. When balls reach sufficient height, gravity causes them to fall, impacting material below. This impact force fractures larger particles into smaller fragments. Impact grinding is most effective with brittle materials and contributes significantly to initial size reduction.

Attrition: Grinding balls sliding against each other and the mill lining create shearing forces. Material trapped between grinding surfaces experiences frictional grinding that progressively reduces particle size. Attrition becomes increasingly important as material becomes finer and impact forces become less effective.

Abrasion: Continuous tumbling creates surface contact between material particles, grinding media, and mill linings. This rubbing action polishes and wears material surfaces, contributing to fine particle production. Abrasion is particularly effective for achieving very fine particle distributions required in specialized applications.

The relative contribution of each mechanism depends on mill design, rotation speed, grinding media characteristics, and material properties.

Material Flow Pattern

Material enters the ball mill through a feed chute or trunnion. Inside the mill, material mixes with grinding media and progresses toward the discharge end. The residence time how long material remains in the mill depends on mill design, rotation speed, and feed rate.

Proper material flow ensures uniform grinding. Poor flow patterns create dead zones where material doesn’t receive adequate grinding, while other areas experience excessive grinding, wasting energy and potentially degrading product quality.

Discharge Mechanisms

Ground material exits the ball mill through discharge systems designed to control particle size:

Overflow discharge: Material exits through the discharge trunnion when the internal level exceeds the trunnion height. This simple mechanism suits fine grinding applications where longer residence time is acceptable.

Grate discharge: Perforated grates allow only adequately ground material to pass, forcing coarse material to remain for additional grinding. This mechanism improves efficiency by preventing over-grinding of fine particles while ensuring complete size reduction.

Request Detailed Technical Specifications →

Types of Ball Mills for Different Applications

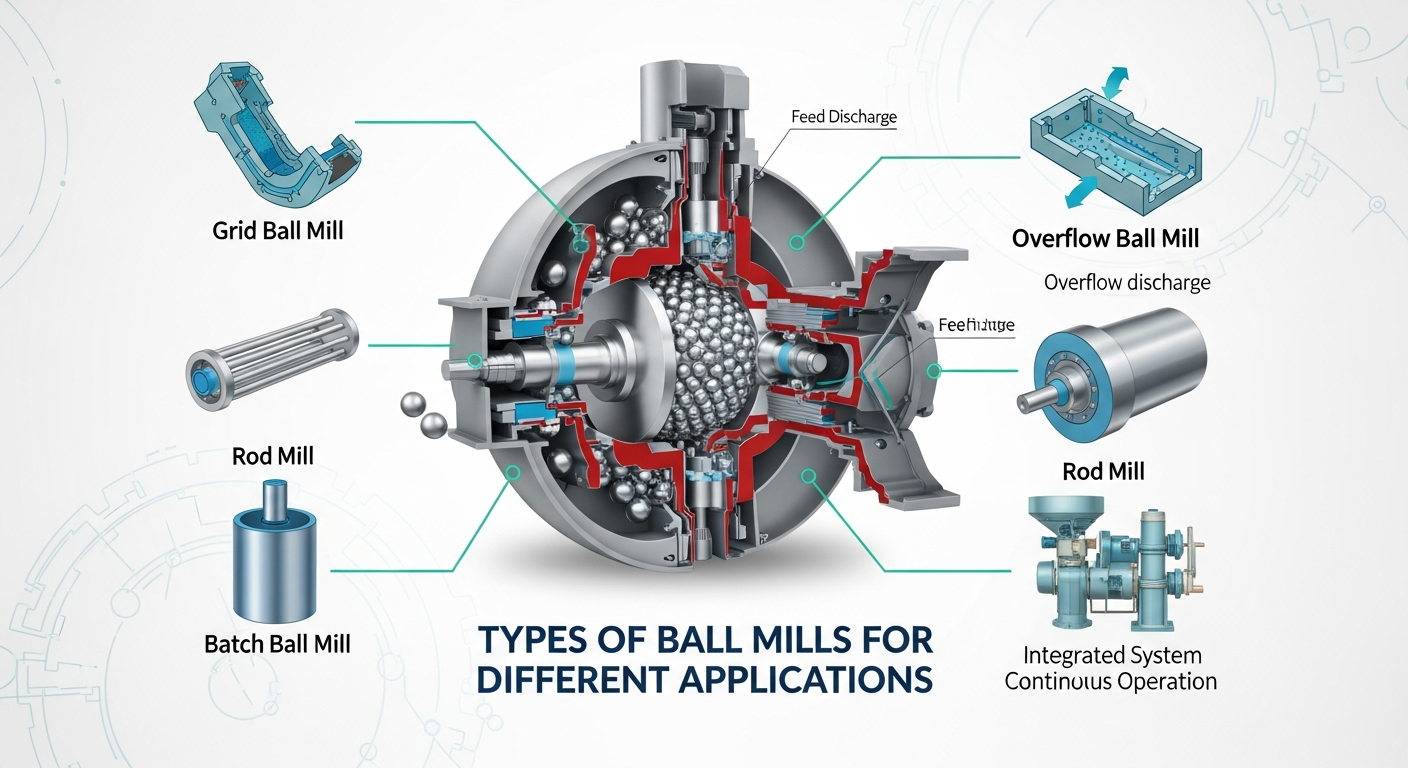

Various ball mill configurations serve specific industrial requirements:

Horizontal Ball Mills

Horizontal designs represent the most common configuration, featuring a cylindrical shell rotating around a horizontal axis. These mills suit continuous processing operations and large-scale production. Horizontal ball mills provide consistent grinding results and are the standard choice for cement plants, mineral processing facilities, and large chemical operations.

Advantages include:

- High throughput capacity

- Continuous operation capability

- Proven reliability across industries

- Wide range of available sizes

- Established maintenance procedures

Vertical Ball Mills

Vertical configurations rotate around a vertical axis, offering a smaller footprint compared to horizontal designs. Gravity assists the grinding process as material and grinding media move downward through the mill. Vertical ball mills are common in chemical processing and pharmaceutical applications requiring batch operations.

Benefits include:

- Space-efficient design

- Easier cleaning between batches

- Better heat dissipation

- Lower installation height requirements

- Suitable for temperature-sensitive materials

Tube Mills

Tube mills are elongated ball mills with length-to-diameter ratios exceeding 3:1. The extended length allows multiple grinding compartments, each potentially containing different ball sizes for progressive size reduction. Tube mills excel at producing very fine products efficiently.

Cement finish grinding represents the primary application for tube mills. Some installations feature tube mills exceeding 15 meters in length, processing hundreds of tons per hour.

Planetary Ball Mills

Laboratory-scale planetary mills feature multiple grinding jars mounted on a rotating platform. The jars rotate on their own axes while revolving around the platform center, creating high-energy grinding conditions. These specialized ball mills achieve extremely fine particle sizes for research and development applications.

Wet vs. Dry Grinding Mills

Wet grinding ball mills process materials mixed with water or other liquids, producing slurries or suspensions. Wet grinding generally achieves finer particle sizes with lower energy consumption and eliminates dust generation concerns.

Dry grinding ball mills process materials without liquid addition, producing dry powder products. Dry grinding suits moisture-sensitive materials and applications where subsequent processing requires dry feeds.

The choice between wet and dry grinding depends on material characteristics, product requirements, and downstream processing needs.

Key Components of a Ball Mill

Understanding ball mill components aids in proper operation and maintenance:

Cylindrical Shell

The shell forms the main body of the ball mill, containing grinding media and material. Shell construction must withstand dynamic loads from tumbling media and material. Thickness and material selection depend on mill size and application severity.

Mill Linings

Protective linings shield the shell from wear and impact. Liner materials include:

- Rubber linings: Economical, quiet operation, suitable for less abrasive materials

- Manganese steel linings: High impact resistance for coarse grinding

- Chromium alloy linings: Superior abrasion resistance for highly abrasive materials

- Ceramic linings: Prevent contamination in pharmaceutical and ceramic applications

Liner design affects grinding efficiency through profile shape and surface characteristics. Wave patterns and lifter bars influence media motion and grinding action.

Trunnions and Bearings

Trunnions are the cylindrical extensions at each end of the mill shell, rotating on large bearings. These bearings support the entire mill weight plus dynamic loads from grinding media motion. Proper lubrication and monitoring are critical for bearing longevity.

Drive System

The drive system rotates the mill at the specified speed. Components include:

- Electric motor: Provides rotational power

- Gear reducer: Reduces motor speed to mill operating speed

- Coupling: Connects reducer output to mill trunnion

- Variable frequency drive (optional): Enables speed optimization

Premium ball mill manufacturers specify reliable drive components ensuring long-term performance and minimal downtime.

Grinding Media

Grinding balls constitute a significant portion of ball mill operating costs. Ball characteristics affecting performance include:

- Material: Steel, high-chrome alloy, ceramic, or rubber-coated

- Size: Ranges from 10mm to 150mm depending on application

- Hardness: Affects wear rate and grinding efficiency

- Density: Influences impact energy

Proper media selection and maintenance optimize grinding efficiency and minimize consumption.

Industrial Applications and Uses

Ball mills serve critical functions across industries:

Cement Production

Cement manufacturing represents the largest application for industrial grinding equipment. Ball mills grind cement clinker combined with gypsum to produce various cement types. The grinding stage consumes significant energy, making efficient equipment essential for profitable operations.

Modern cement plants use closed-circuit grinding systems where classifiers separate fine particles while returning coarse material for additional grinding. This arrangement improves energy efficiency and product quality.

Mining and Mineral Processing

Ore grinding liberates valuable minerals from host rock, enabling effective separation. Gold mines grind ore to extremely fine sizes (often below 75 microns) for cyanidation. Copper concentrators grind ore to liberate copper minerals for flotation separation. Iron ore processing grinds material to enhance magnetic separation.

The ball mill circuit often represents the single largest operating cost in mineral processing facilities, making equipment efficiency and reliability paramount.

Pharmaceutical Manufacturing

Pharmaceutical production requires precise particle size control affecting drug dissolution, bioavailability, and formulation stability. Ball mills provide controlled grinding environments meeting stringent quality requirements.

Pharmaceutical ball mills typically feature stainless steel construction, smooth internal surfaces for cleaning, and batch operation capabilities preventing cross-contamination.

Chemical Processing

Chemical manufacturers grind compounds for catalysts, pigments, specialty chemicals, and intermediate products. Applications range from producing fine catalyst supports to dispersing pigments in various media.

Ceramic Industries

Ceramic production grinds raw materials including clay, feldspar, quartz, and kaolin. Wet grinding in ball mills produces uniform slurries for casting, spray drying, or direct forming. Particle size distribution affects final ceramic properties including strength, porosity, and surface finish.

Selecting the Right Ball Mill Manufacturer

Choosing a reliable ball mill manufacturer impacts equipment performance, operational costs, and long-term success:

Manufacturing Experience

Established manufacturers bring accumulated knowledge about design optimization, material selection, and application-specific requirements. Shalimar Engineering has manufactured industrial equipment for numerous industries, understanding the nuances that differentiate good equipment from excellent equipment.

Engineering Capabilities

Custom engineering ensures ball mills match specific application requirements. Manufacturers offering customization can optimize:

- Mill dimensions for available space and capacity needs

- Materials of construction for corrosive or abrasive environments

- Drive systems for energy efficiency and operational flexibility

- Discharge arrangements for product quality control

- Integration with existing processing equipment

Quality Standards

Quality manufacturing determines equipment reliability and longevity. Look for manufacturers following ISO 9001 quality management systems and providing comprehensive documentation including material test certificates and fabrication records.

Technical Support

Comprehensive support services distinguish excellent ball mill suppliers from average vendors:

- Pre-installation consultation and site assessment

- Installation supervision and commissioning

- Operator training programs

- Troubleshooting assistance for operational issues

- Spare parts availability with quick delivery

- Preventive maintenance programs

Shalimar Engineering provides complete technical support throughout equipment lifecycles, ensuring clients achieve optimal performance and maximum return on investment.

Energy Efficiency

Energy costs represent significant operational expenses. Modern ball mill designs incorporate features reducing power consumption:

- Optimized mill geometry

- Variable frequency drives

- High-efficiency motors

- Integrated classifiers for closed-circuit operation

Energy-efficient equipment from leading manufacturers provides substantial savings over equipment lifespan.

Get Your Custom Ball Mill Quote Today →

Operational Parameters Affecting Performance

Several factors influence ball mill efficiency:

Mill Speed

Operating speed affects grinding mechanisms and efficiency. Too slow produces excessive sliding with minimal cascading, reducing grinding effectiveness. Too fast approaches critical speed where media centrifuges against the shell without cascading.

Mill Filling

The percentage of mill volume occupied by grinding media affects capacity and efficiency. Typical filling ranges from 25-45% of mill volume. Lower filling suits fine grinding, while higher filling increases throughput for coarser grinding.

Material Feed Rate

Feed rate must balance with mill capacity. Underfeeding wastes installed capacity and increases energy consumption per ton. Overfeeding reduces residence time, producing inadequately ground product.

Grinding Media Characteristics

Ball size distribution, material hardness, and charge level significantly impact performance. Larger balls suit coarse grinding, while smaller balls produce finer products. Worn balls require periodic replacement maintaining optimal size distribution.

Maintenance Requirements

Proper maintenance extends ball mill operational life:

Daily Monitoring

Operators should monitor bearing temperatures, unusual noises, vibration levels, and power consumption. Deviations from normal parameters indicate developing problems requiring investigation.

Periodic Inspections

Regular inspections assess:

- Liner wear and remaining life

- Grinding media level and size distribution

- Bearing condition and lubrication

- Drive system alignment and coupling condition

- Structural integrity of shell and trunnions

Scheduled Maintenance

Maintenance activities include:

- Lubrication replenishment following manufacturer schedules

- Liner replacement based on wear measurements

- Bearing inspection and replacement as needed

- Gear oil changes at specified intervals

- Bolt tightness verification preventing loosening

Reliable ball mill manufacturers provide detailed maintenance manuals and training ensuring proper equipment care.

Shalimar Engineering: Your Trusted Partner

Shalimar Engineering combines manufacturing excellence with customer-focused service as a leading ball mill manufacturer in India:

✓ Decades of manufacturing experience across industries

✓ Custom-engineered solutions for specific applications

✓ Quality construction using premium materials

✓ Energy-efficient designs reducing operational costs

✓ Comprehensive technical support and service

✓ Competitive pricing with transparent quotations

✓ Pan-India service network for prompt support

Conclusion

Understanding what a ball mill is, its working principle, and available types enables informed equipment selection decisions. These versatile grinding machines serve critical functions across industries, making proper equipment choice and manufacturer selection crucial for operational success.

Working with experienced ball mill manufacturers like Shalimar Engineering ensures you receive equipment designed for reliability, efficiency, and longevity. Quality manufacturing, custom engineering, competitive pricing, and comprehensive support make proper manufacturer selection as important as choosing the right equipment type.

For detailed specifications, application-specific recommendations, and competitive quotations, contact Shalimar Engineering to discuss your grinding requirements and receive expert guidance on optimal solutions for your operations.

Get started with India’s trusted ball mill manufacturer today!