Selecting the appropriate grinding equipment stands as one of the most critical decisions in setting up or upgrading a production facility. The grinding process directly impacts product quality, operational efficiency, and overall profitability. Understanding what makes a ball mill suitable for specific applications helps industries make informed investment decisions that deliver long-term value.

This comprehensive guide examines essential factors that influence equipment selection, from technical specifications to supplier evaluation. Whether establishing a new production line or replacing existing equipment, these insights will help you navigate the selection process with confidence.

Understanding Ball Mill Fundamentals

A ball mill operates as a cylindrical shell that rotates around its horizontal axis, containing grinding media (typically steel or ceramic balls) that cascade and tumble, reducing material size through impact and attrition. This time-tested technology remains widely used across industries for its reliability, versatility, and ability to achieve consistent particle size reduction.

The basic components include a cylindrical shell, grinding media, inlet and outlet systems, drive mechanisms, and supporting structures. As the shell rotates, balls lift along the rising side and cascade down, crushing materials trapped between them. The grinding action occurs through compression, impact, and friction as materials pass through the mill.

Different mill configurations serve various purposes. Overflow mills discharge material through the outlet end when it reaches a certain level. Grate discharge mills use internal grates to retain larger particles while allowing fine material to exit. Each design offers distinct advantages depending on application requirements and desired product characteristics.

The grinding media plays a crucial role in performance. Steel balls provide economical grinding for most applications, while ceramic or porcelain media suit processes requiring contamination-free products. Media size, typically ranging from 10mm to 100mm diameter, affects grinding efficiency and final product fineness.

Production Capacity Requirements

Determining required production capacity forms the foundation of equipment selection. Accurate capacity assessment prevents underutilization of capital investments or insufficient production capability that constrains business growth.

Current and Future Demand Analysis

Start by evaluating current production requirements and projected growth over the equipment’s expected lifespan. Consider market trends, business expansion plans, and potential product line diversification. Building in 20-30% capacity buffer accommodates demand fluctuations and provides growth headroom without immediate equipment additions.

Production schedules influence capacity calculations. Continuous 24-hour operations require different capacity considerations than single-shift operations. Maintenance downtime, startup periods, and planned shutdowns reduce effective operating hours, requiring higher nominal capacity to meet actual production targets.

Material Characteristics Impact

Material properties significantly affect throughput capacity. Feed size distribution, hardness, moisture content, and abrasiveness all influence grinding rates. Harder materials require longer residence times, reducing effective throughput. High moisture content can cause material buildup, decreasing efficiency.

Work index measurements quantify material grindability, helping predict energy requirements and throughput rates. Testing representative material samples provides data for accurate capacity calculations. Consult with experienced ball mill manufacturer representatives who can interpret work index data and recommend appropriate equipment sizing.

Particle Size Requirements

Target product fineness directly impacts capacity. Finer grinding requires more energy and longer residence times, reducing throughput. Achieving 200 mesh powder requires significantly different residence time compared to 80 mesh output. Balance product specifications against capacity requirements when selecting equipment size.

Material Processing Considerations

Understanding your specific material characteristics and processing requirements guides appropriate equipment selection and configuration choices.

Feed Material Properties

Feed material hardness, measured on the Mohs scale, determines grinding media requirements and expected wear rates. Soft materials (Mohs 2-4) grind easily but may require special considerations to prevent over-grinding. Hard materials (Mohs 6-9) demand robust construction and wear-resistant components.

Abrasiveness impacts liner and grinding media consumption. Highly abrasive materials increase operational costs through accelerated wear. Selecting appropriate liner materials and grinding media compositions helps manage these costs while maintaining productivity.

Moisture content affects flowability and grinding efficiency. Materials with 3-5% moisture often grind optimally, while higher moisture can cause material adherence to mill internals. Some applications require drying before grinding, while others benefit from wet grinding approaches.

Process Requirements

Dry grinding versus wet grinding represents a fundamental choice affecting equipment design and auxiliary systems. Dry grinding produces powders ready for use in many applications, eliminating drying costs. However, wet grinding often achieves finer particle sizes, reduces dust concerns, and simplifies material handling.

Temperature sensitivity of materials influences operational parameters. Heat-sensitive materials may require cooling systems, lower rotational speeds, or intermittent operation to prevent degradation. Some mills incorporate jacket cooling or internal cooling coils for temperature control.

Contamination concerns affect construction materials and grinding media selection. Food, pharmaceutical, and specialty chemical applications may require stainless steel construction and ceramic grinding media to maintain product purity. Standard carbon steel construction with steel grinding media suits most industrial mineral applications.

Technical Specifications and Performance Parameters

Several critical technical parameters determine whether a ball mill machine meets specific production requirements.

Mill Dimensions and Volume

Shell diameter and length establish mill volume, the primary determinant of capacity. Larger diameters accommodate larger grinding media, beneficial for coarser grinding. Length-to-diameter ratios typically range from 1:1 for coarse grinding to 3:1 or higher for fine grinding applications.

Effective grinding volume, accounting for voids between grinding media and mill free volume, determines actual processing capacity. Mills operate most efficiently at 40-50% media filling, leaving sufficient space for material and ball movement.

Rotational Speed

Operating speed significantly impacts grinding efficiency. Critical speed represents the rotational speed at which grinding media centrifuges against the shell without cascading. Mills typically operate at 65-80% of critical speed, providing optimal cascading action.

Slower speeds produce more grinding through attrition and compression, suitable for fine grinding. Higher speeds increase impact forces, beneficial for coarse grinding of harder materials. Variable speed drives enable optimization for different materials and products.

Power Requirements

Motor power requirements depend on mill size, rotational speed, and grinding media load. Proper motor sizing ensures adequate power for startup torque and continuous operation across varying load conditions. Undersized motors lead to frequent failures and operational limitations, while oversized motors waste energy and increase capital costs.

Drive systems include direct drive, gear reduction, or belt drives. Direct drives offer simplicity but require specialized motors. Gear reducers provide flexibility in speed selection and use standard motors. Belt drives offer lowest cost but require maintenance and have efficiency losses.

Liner Design and Materials

Internal liners protect the shell from wear and optimize grinding action. Liner profiles smooth, ribbed, or specialized patterns affect grinding media movement and material flow. Ribbed liners lift media higher before cascading, increasing impact forces.

Liner materials balance wear resistance, cost, and operational considerations. Manganese steel provides excellent wear resistance for abrasive materials. Rubber liners reduce noise, protect against corrosion, and suit less abrasive applications. Chrome-moly steel offers intermediate performance and cost.

Evaluating Ball Mill Manufacturer Credentials

Selecting a reliable ball mill manufacturer proves as important as choosing the right equipment specifications. Manufacturing quality, engineering support, and after-sales service significantly impact long-term satisfaction and operational success.

Manufacturing Capabilities

Visit manufacturing facilities when possible to assess production capabilities firsthand. Modern fabrication equipment, quality control systems, and organized production processes indicate professional operations. Certifications like ISO 9001 for quality management validate manufacturing processes.

Manufacturing experience in your specific industry or application provides valuable perspective. Manufacturers serving similar industries understand unique challenges and requirements, bringing proven solutions rather than experimental approaches.

Fabrication quality directly affects equipment longevity and performance. Precise machining of bearing surfaces, proper welding procedures, and accurate assembly ensure smooth operation and minimize premature wear. Request information about welding certifications, machining tolerances, and quality inspection procedures.

Engineering Support

Comprehensive engineering support helps optimize equipment selection and configuration. Pre-sales technical consultation should include material testing, capacity calculations, and custom design recommendations based on specific requirements. Access to experienced engineers who understand grinding theory and practical applications adds significant value.

Computational modeling capabilities enable performance predictions before equipment fabrication. Finite element analysis validates structural designs, while process modeling predicts grinding performance. These engineering tools reduce risk and optimize designs for specific applications.

Customization capabilities address unique requirements that standard equipment cannot meet. Whether special materials of construction, unusual dimensions, or integrated auxiliary systems, manufacturing flexibility ensures equipment matches precise needs.

Project Execution Capabilities

Complete project responsibility simplifies implementation. Suppliers offering turnkey solutions including equipment supply, installation supervision, commissioning, and operator training streamline project execution and establish clear accountability.

Installation documentation and commissioning protocols ensure proper setup. Detailed installation drawings, foundation requirements, and assembly instructions guide construction activities. Comprehensive commissioning procedures verify performance before handover.

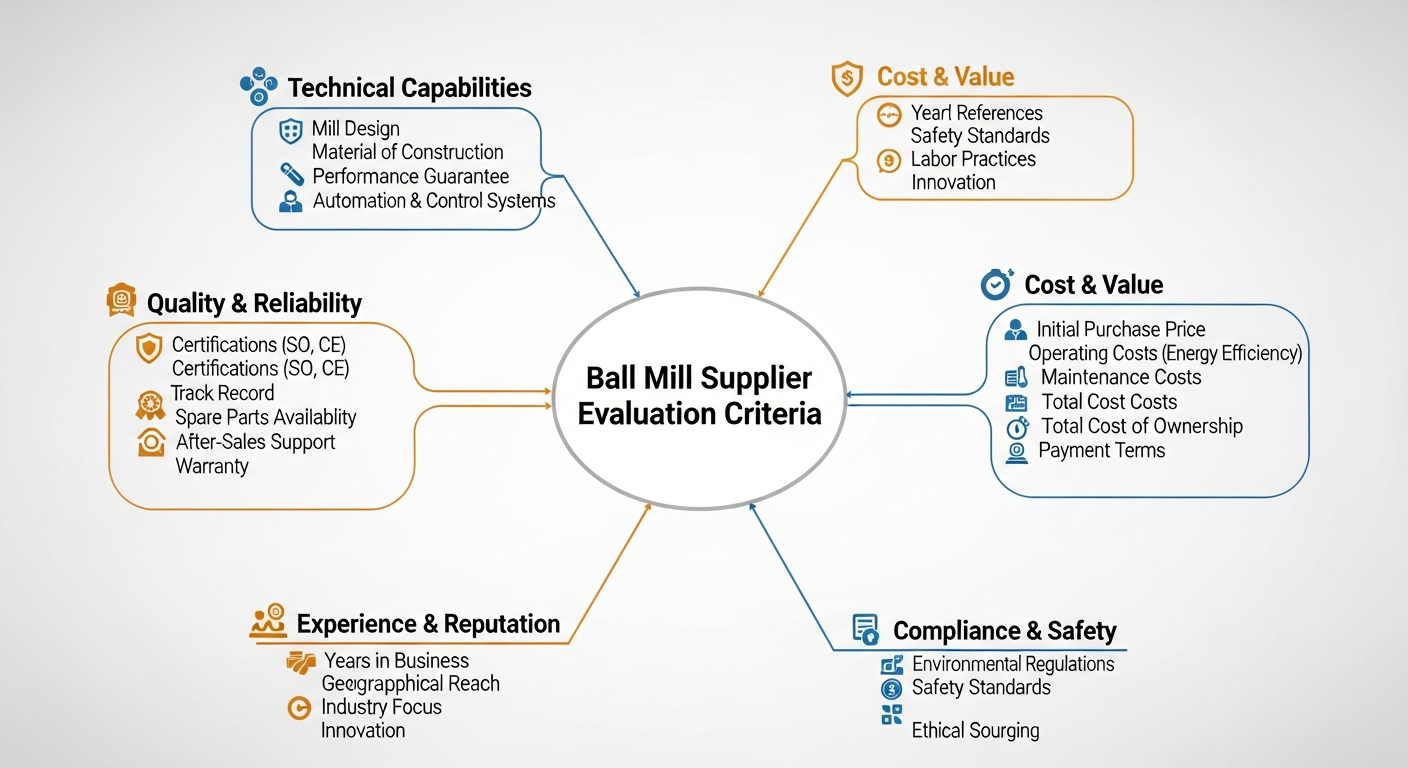

Ball Mill Supplier Evaluation Criteria

Beyond manufacturing capabilities, several factors distinguish exceptional ball mill supplier companies from average vendors.

After-Sales Service Infrastructure

Local service presence significantly impacts operational support quality. Service technicians familiar with equipment can respond quickly to issues, minimizing downtime. Remote support capabilities, including video assistance and remote diagnostics, provide immediate help for troubleshooting.

Spare parts availability determines maintenance efficiency. Critical wear parts liners, grinding media, bearings, seals should be readily available with short lead times. Comprehensive spare parts programs with recommended inventories help plan maintenance activities.

Preventive maintenance programs extend equipment life and prevent unexpected failures. Scheduled inspections, vibration analysis, oil analysis, and component replacement recommendations keep equipment operating reliably. Some suppliers offer complete maintenance contracts, assuming responsibility for equipment availability.

Training and Knowledge Transfer

Comprehensive operator training develops workforce capabilities essential for optimal equipment operation. Training should cover operational theory, startup and shutdown procedures, routine maintenance, troubleshooting, and safety protocols. Well-trained operators recognize abnormal conditions early and implement appropriate responses.

Maintenance training programs educate facility maintenance staff on proper servicing techniques. Hands-on training on critical maintenance tasks bearing replacement, liner installation, alignment procedures builds internal capabilities that reduce dependence on external service providers.

Documentation quality impacts ongoing operations. Comprehensive operation and maintenance manuals, parts lists with diagrams, and troubleshooting guides serve as valuable references. Clear documentation in local languages improves usability for operational staff.

Performance Guarantees

Equipment performance guarantees provide assurance and risk mitigation. Capacity guarantees, energy consumption commitments, and product fineness assurances establish clear expectations. Understand guarantee conditions, testing protocols, and remedies if performance falls short.

Warranty coverage protects against manufacturing defects and premature component failures. Standard warranty periods typically cover 12-24 months from commissioning. Understand what components are covered, warranty exclusions, and claim procedures.

The Ball Mill Market in India

India’s growing industrial sector has created substantial demand for grinding equipment across multiple industries. Understanding the landscape of ball mill manufacturers in india helps industries identify local sourcing opportunities.

Domestic Manufacturing Capabilities

The “Make in India” initiative has strengthened domestic manufacturing capabilities for heavy industrial equipment. Local ball mill machine manufacturers in india combine international technology with indigenous engineering, delivering equipment that meets global standards at competitive prices.

Domestic manufacturing offers several advantages. Shorter delivery times compared to imports accelerate project schedules. Local currency transactions eliminate foreign exchange risks. Easier communication and site visits simplify technical discussions and problem-solving.

Quality levels among Indian manufacturers vary significantly. Leading manufacturers maintain facilities comparable to international standards, while smaller operations may have limited capabilities. Thorough evaluation separates world-class manufacturers from marginal producers.

Comprehensive Supply Ecosystem

The supporting ecosystem around grinding equipment includes various specialized suppliers. Ball mill balls suppliers provide grinding media in various materials, sizes, and specifications. Establishing relationships with reliable media suppliers ensures consistent supply of this critical consumable.

Component suppliers provide replacement parts including bearings, seals, gears, and motors. A developed supplier network simplifies maintenance and reduces downtime. Some equipment manufacturers maintain strategic partnerships with component suppliers, ensuring parts availability and compatibility.

Service provider networks offer specialized services including installation, commissioning, maintenance, and troubleshooting. Independent service companies can supplement manufacturer support, particularly for older equipment or when manufacturer support proves inadequate.

Energy Efficiency and Operating Costs

Operating costs significantly impact project economics over equipment lifetime. Energy represents the largest operational expense for most grinding applications, making efficiency a critical selection factor.

Power Consumption Optimization

Grinding efficiency, measured as energy required per ton of material processed, varies substantially between equipment designs and operating conditions. Modern mill designs incorporating optimized liner profiles, proper media selection, and controlled operating parameters achieve better efficiency than older designs.

Media filling percentage affects power consumption and grinding efficiency. Optimal filling ranges from 40-50% of mill volume, balancing grinding action with power draw. Underfilling reduces grinding capacity, while overfilling increases power consumption without proportional productivity gains.

Operational parameters including rotational speed, feed rate, and media size distribution require optimization. Systematic testing identifies optimal settings for specific materials and products. Process control systems can automatically adjust parameters to maintain optimal efficiency across varying conditions.

Maintenance Cost Management

Regular maintenance prevents costly breakdowns and extends equipment life. Predictive maintenance strategies using vibration analysis, thermography, and oil analysis identify developing issues before failures occur. This proactive approach minimizes unplanned downtime and reduces repair costs.

Liner life directly impacts maintenance costs and downtime. Proper liner material selection, installation techniques, and operational practices maximize liner longevity. Some operations maintain multiple liner sets, enabling quick replacement during scheduled maintenance windows.

Grinding media consumption represents a significant ongoing cost. Media consumption rates depend on material hardness, mill design, and media quality. Cost-effective media sourcing, proper sizing, and periodic media additions maintain grinding efficiency while controlling costs.

Safety and Environmental Considerations

Modern industrial operations prioritize worker safety and environmental protection. Equipment selection should consider safety features and environmental impacts.

Safety Features and Systems

Proper guarding prevents access to rotating components and pinch points. Mill enclosures, access doors with interlocks, and warning signs establish multiple safety barriers. Emergency stop systems enable rapid shutdown during unusual conditions.

Dust control systems protect workers and maintain facility cleanliness. Mill enclosures with dust collection connections capture airborne particles. Proper ventilation and air filtration systems maintain air quality in grinding areas.

Noise control measures protect worker hearing and reduce environmental noise pollution. Enclosures with sound-absorbing materials, vibration isolation mounts, and proper foundation design minimize noise generation and transmission.

Environmental Performance

Dust emissions regulations require effective control measures. Baghouse filters, cyclones, or electrostatic precipitators capture particulate emissions. Properly designed and maintained systems achieve compliance with stringent environmental regulations.

Energy efficiency directly impacts environmental footprint. Lower energy consumption reduces greenhouse gas emissions and operating costs. When evaluating equipment options, consider lifecycle environmental impacts alongside economic factors.

Waste management practices address spent liner materials, worn grinding media, and maintenance wastes. Recycling programs recover valuable materials, reducing disposal costs and environmental impacts. Some liner and media suppliers operate takeback programs, simplifying waste management.

Financial Analysis and Investment Planning

Capital equipment investments require thorough financial analysis justifying expenditures to decision-makers and ensuring alignment with business objectives.

Capital Cost Components

Equipment purchase price represents only one element of total project cost. Installation costs including civil works, electrical infrastructure, material handling systems, and auxiliary equipment often equal or exceed equipment costs. Comprehensive budgeting accounts for all capital expenditure components.

Auxiliary systems including feeders, conveyors, classifiers, and dust collection equipment add substantial cost. These supporting systems prove essential for complete grinding systems, requiring careful planning and budgeting.

Operating Cost Analysis

Detailed operating cost projections help evaluate alternatives and establish operating budgets. Major cost categories include energy consumption, grinding media, maintenance labor and materials, operator labor, and consumables like lubricants and seals.

Comparing operating costs between equipment alternatives reveals long-term economic implications. A more expensive mill with better efficiency may deliver lower lifecycle costs than a cheaper, less efficient alternative. Total cost of ownership analysis provides comprehensive economic comparison.

Return on Investment

Productivity improvements, quality enhancements, and cost reductions from new equipment generate financial returns. Quantifying benefits increased production capacity, reduced reject rates, lower operating costs supports investment justification.

Payback period calculations show how quickly investments generate returns. Simple payback divides capital investment by annual cost savings or profit improvements. More sophisticated analyses account for time value of money through discounted cash flow methods.

Conclusion

Selecting the right ball mill machine for your production line involves careful analysis of numerous technical, operational, and commercial factors. Production capacity requirements, material characteristics, technical specifications, and supplier capabilities all influence the optimal choice.

Working with experienced ball mill machine manufacturers who understand your specific application requirements simplifies the selection process. Their expertise in grinding theory, equipment design, and practical operations helps identify solutions matching your exact needs.

Get high-performance ball mill solutions from Shalimar Engineering – Contact us today for customized grinding systems tailored to your production requirements.

Frequently Asked Questions (FAQ)

1. What is the primary function of a ball mill in a production line?

A ball mill reduces the size of raw materials through impact and friction. It grinds materials into fine powder or specific particle sizes required for downstream processes such as blending, reacting, or finishing.

2. How do I determine the right capacity for my ball mill?

Capacity depends on material hardness, required output, operating hours, and projected demand. Evaluating both current needs and future expansion plans ensures the mill has adequate performance without becoming oversized.

3. Does material hardness affect ball mill selection?

Yes. Harder materials require higher energy input, longer residence time, and more durable liners and grinding media. Material characteristics directly influence mill size, motor rating, and liner design.

4. What is the difference between an overflow mill and a grate discharge mill?

Overflow mills release material once it reaches a defined level inside the shell, making them suitable for fine grinding. Grate discharge mills use internal grates to control particle size and allow faster discharge, ideal for coarser grinding.

5. Is wet grinding better than dry grinding?

Wet grinding provides smoother flow, improved fineness, and reduced dust. Dry grinding is preferred when moisture-sensitive products or downstream drying steps are not required. The choice depends on product specifications and operational conditions.