Industrial powder production stands as a cornerstone of modern manufacturing, supplying countless industries with precisely sized materials essential for their processes. From cement and ceramics to pharmaceuticals and paints, fine powders enable product functionality and performance. Understanding the mechanisms behind powder production helps industries optimize their operations and achieve consistent product quality.

The transformation of coarse raw materials into uniform fine powders requires sophisticated equipment capable of applying mechanical forces in controlled environments. This comprehensive guide examines how grinding technology converts bulk materials into valuable powdered products, the science behind particle size reduction, and practical considerations for industrial applications.

The Fundamental Principle of Size Reduction

Particle size reduction occurs when mechanical forces exceed the structural strength of materials, causing them to fracture into smaller pieces. This seemingly simple concept involves complex interactions between applied forces, material properties, and equipment design. Three primary mechanisms accomplish size reduction: compression, impact, and attrition.

Compression forces squeeze materials between two surfaces, creating stress concentrations that propagate cracks through the material structure. This mechanism proves most effective for brittle materials that fracture readily under compressive loads. Stones, minerals, and ceramic materials respond well to compression grinding.

Impact forces strike materials at high velocity, transferring kinetic energy that causes fracturing. The sudden energy transfer creates stress waves within materials, initiating crack formation and propagation. Impact grinding suits both brittle and semi-brittle materials, providing rapid size reduction for many applications.

Attrition involves grinding materials between surfaces moving relative to each other, producing shearing forces that wear away material surfaces. This gentler mechanism achieves fine grinding without generating excessive heat or causing unwanted material transformations. Soft to medium-hardness materials benefit from attrition grinding.

How Ball Mill Technology Works

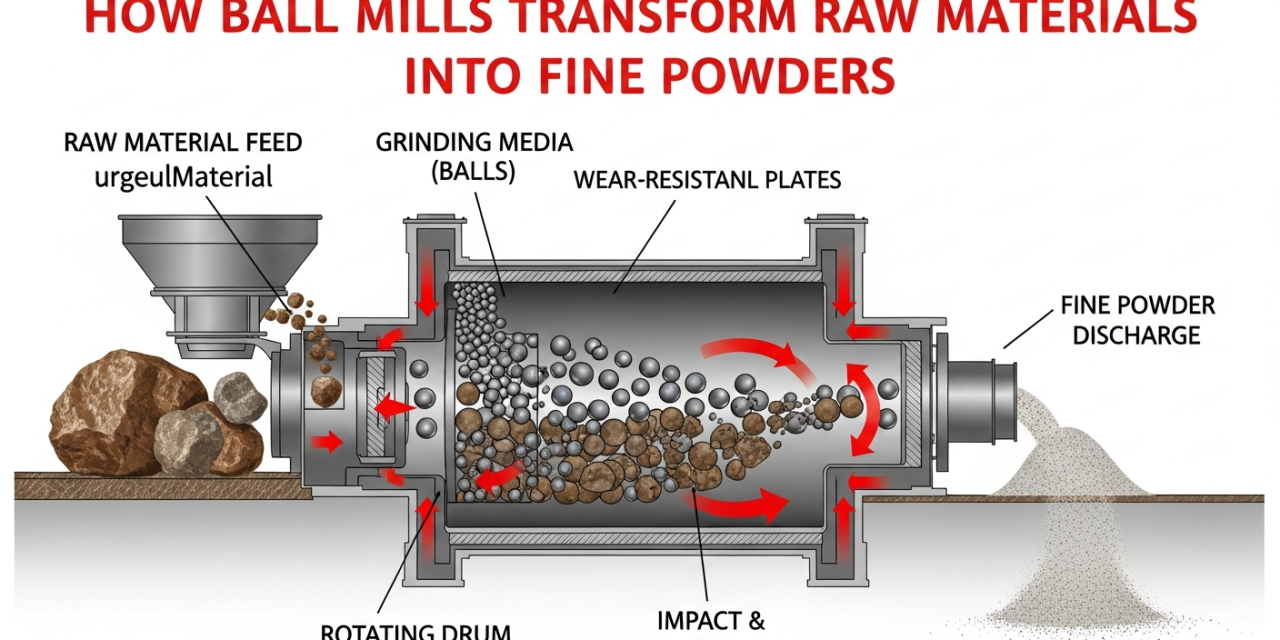

A ball mill harnesses all three grinding mechanisms through an elegantly simple design. The cylindrical shell rotates around its horizontal axis, containing grinding media (typically steel or ceramic balls) that cascade, tumble, and roll within the chamber. Materials introduced into this dynamic environment experience repeated impacts, compression, and attrition until achieving desired fineness.

The Grinding Chamber Design

The shell forms a hollow cylinder constructed from steel plate, often lined with wear-resistant materials to protect against abrasion and impact. Shell dimensions diameter and length determine grinding volume and influence grinding characteristics. Larger diameters accommodate bigger grinding media suitable for coarser work, while longer shells provide extended residence time for finer grinding.

Internal liners serve multiple functions beyond wear protection. Liner profiles affect how grinding media moves within the chamber. Smooth liners allow media to slide and cascade smoothly, while ribbed or wave-pattern liners lift media higher before releasing it to fall, increasing impact forces. Liner material selection balances wear resistance, cost, and operational requirements.

End caps seal the grinding chamber while providing material inlet and outlet passages. Various discharge arrangements suit different applications. Overflow discharge allows material to exit when reaching the outlet end elevation. Grate discharge systems use internal grates to retain coarse particles while permitting fine material to exit, improving grinding efficiency for many applications.

Grinding Media Dynamics

Grinding media fill approximately 40-50% of the mill volume, creating optimal conditions for size reduction. As the shell rotates, centrifugal force carries balls upward along the rising side until gravity overcomes centrifugal force, causing them to cascade or cataracts downward. Materials caught in this cascading zone experience intense grinding action.

Media size distribution significantly influences grinding performance. Larger balls (50-100mm diameter) provide greater impact forces suitable for breaking coarse feed materials. Smaller balls (10-30mm diameter) offer more contact points and surface area, achieving finer grinding through attrition and compression. Most operations use graded media mixtures that provide both coarse and fine grinding capabilities.

Media material selection depends on application requirements. Steel balls offer economical grinding for most industrial minerals and materials where some iron contamination proves acceptable. Chrome steel or stainless steel media suits applications requiring reduced contamination. Ceramic or porcelain media provides contamination-free grinding essential for pharmaceuticals, food products, and specialty chemicals.

Rotational Speed and Grinding Action

Operating speed critically affects grinding efficiency. Critical speed represents the rotational velocity at which centrifugal force holds grinding media against the shell without cascading. Mills typically operate at 65-80% of critical speed, providing optimal media movement and grinding action.

At lower speeds (50-65% of critical speed), grinding media cascades in sheets, providing grinding through attrition and compression. This regime suits fine grinding applications where impact forces might damage heat-sensitive materials or cause unwanted structural changes.

Higher speeds (75-85% of critical speed) create more vigorous cascading with increased impact forces. This regime effectively handles coarser grinding and harder materials requiring aggressive size reduction. The violent action rapidly breaks large particles, though it generates more heat and noise.

The Grinding Process Step by Step

Understanding the sequential transformation materials undergo within a ball mill machine reveals how coarse feed becomes fine powder through progressive size reduction.

Material Introduction and Initial Breakdown

Raw materials enter the mill through the feed trunnion, typically as lumps or coarse particles ranging from a few millimeters to several centimeters. Initial impacts from large grinding balls rapidly fracture these feed particles into progressively smaller pieces. This stage proceeds quickly as coarse materials present large, easily fractured structures.

Feed rate control maintains optimal mill loading. Underfeeding wastes grinding capacity and increases media wear through ball-on-ball contact. Overfeeding reduces grinding efficiency as excessive material cushions impacts and prevents effective grinding action. Proper feed control balances productivity with grinding efficiency.

Progressive Size Reduction

As materials break into smaller particles, they migrate toward regions with smaller grinding media. The natural segregation within grinding chambers places larger media near the feed end and smaller media toward the discharge end. This progression provides matched grinding intensity as materials become finer.

Residence time and how long materials remain within the mill determines final particle size. Longer residence times achieve finer products as materials experience more grinding cycles. Mills operating in closed circuit with classifiers separate fine products from coarser material requiring additional grinding, improving overall system efficiency.

The fracture process continues until particles reach a size where their structural strength exceeds applied forces, or where surface-to-volume ratios make further size reduction energy-intensive and slow. This represents the practical grinding limit for given operating conditions.

Final Product Discharge

Materials exit the mill when reaching appropriate fineness and mill residence time. Overflow mills discharge material continuously as new feed pushes earlier material toward the outlet. The overflow design produces relatively uniform particle size distributions suitable for many applications.

Grate discharge systems actively separate fine product from coarser material requiring additional grinding. Grates positioned ahead of the discharge opening retain particles above specified size while allowing fine material to pass. This arrangement increases capacity and improves energy efficiency for applications requiring specific particle sizes.

Some installations incorporate air-swept designs where controlled airflow carries fine particles out of the grinding zone while leaving coarser material for continued grinding. This approach prevents over-grinding and improves efficiency for producing specific particle size distributions.

Factors Influencing Grinding Efficiency

Multiple variables affect how effectively a ball mill machine converts raw materials into fine powders. Understanding these factors enables optimization for specific applications and materials.

Material Properties

Material hardness, measured on the Mohs scale, fundamentally determines grinding energy requirements. Soft materials (Mohs 2-4) like gypsum or talc grind easily with minimal energy input. Hard materials (Mohs 6-9) like quartz or corundum require substantially more energy and longer grinding times.

Material brittleness affects fracture behavior. Brittle materials fracture cleanly under impact and compression, grinding efficiently. Ductile or plastic materials tend to deform rather than fracture, making them more difficult to grind and often requiring special techniques.

Moisture content significantly impacts grinding behavior. Most materials grind most efficiently at 1-3% moisture. Higher moisture causes materials to adhere to media and liners, reducing grinding efficiency and mill capacity. Some applications employ wet grinding, dispersing materials in water or other liquids to improve grinding efficiency and prevent dust.

Operating Parameters

Feed size distribution affects grinding efficiency. Properly sized feed that matches mill capabilities optimizes throughput and product quality. Oversized feed requires excessive energy to break down initial particles. Extremely fine feed wastes grinding capacity on material already approaching target size.

Media filling percentage directly influences grinding action and power consumption. Optimal filling typically ranges from 40-50% of mill volume. Lower filling reduces grinding capacity and increases wear from media-on-media contact. Excessive filling creates cushioning that reduces grinding effectiveness while increasing power requirements.

Media size distribution should match the grinding task. Initial grinding of coarse feed requires larger media for impact energy. Fine grinding benefits from smaller media providing greater surface area. Many operations use graded media charges that provide both coarse and fine grinding capabilities within a single mill.

Equipment Design Features

Liner design affects grinding media movement patterns and grinding efficiency. Smooth liners promote cascading motion suitable for fine grinding through attrition. Ribbed or wave-pattern liners lift media higher, increasing impact forces for coarse grinding. Some designs incorporate lifter bars that positively lift media to controlled heights before releasing.

Length-to-diameter ratio influences grinding characteristics. Short mills (L/D ratio near 1:1) suit coarse grinding with high media velocities and impact forces. Long mills (L/D ratio 2:1 or greater) provide extended residence time for fine grinding through progressive size reduction.

Discharge arrangements affect product characteristics and grinding efficiency. Overflow discharge produces broad particle size distributions. Grate discharge with proper grate design can sharpen product size distribution and improve grinding efficiency by removing finished product promptly.

Industrial Applications and Material Processing

The versatility of grinding technology enables powder production across diverse industries, each with specific requirements and challenges. Working with experienced ball mill manufacturer companies helps industries select appropriate equipment configurations for their applications.

Cement Production

Cement manufacturing represents the largest application for industrial grinding. Raw materials including limestone, clay, and iron ore undergo grinding to create raw meal for the kiln. After calcination, cement clinker requires grinding with gypsum to produce finished cement powder.

Cement grinding demands high capacity and energy efficiency. Modern installations incorporate high-efficiency classifiers in closed circuit with mills, separating fine cement from coarser material requiring additional grinding. This arrangement improves energy efficiency by 25-30% compared to open circuit operations.

Fineness requirements typically target 3000-4000 cm²/g Blaine surface area, corresponding to particles predominantly in the 10-50 micron range. Proper grinding produces particle size distributions that optimize cement strength development and workability.

Mineral Processing

Mining and mineral processing operations use grinding to liberate valuable minerals from gangue materials. Ore grinding represents a critical step preceding concentration processes like flotation, magnetic separation, or gravity concentration.

Liberation size the particle size at which valuable minerals separate from waste minerals determines required grinding fineness. Some ores require grinding to 200 mesh (75 microns) or finer for effective liberation. Achieving this fineness economically requires properly designed grinding circuits.

Multi-stage grinding with classification between stages optimizes energy consumption. Coarse grinding in larger mills breaks ore to intermediate sizes. Fine grinding in smaller mills reduces classification overflow to final target fineness. This staged approach matches grinding intensity to material size.

Ceramic and Refractory Materials

Ceramic manufacturing requires grinding of raw materials including clays, feldspars, and fluxes into fine powders for forming and firing. Precise particle size distributions affect ceramic properties including plasticity, drying behavior, and fired characteristics.

Contamination concerns often dictate equipment specifications. White ceramics require contamination-free grinding using ceramic or porcelain media in rubber-lined mills. Industrial ceramics may tolerate steel media but still require material selection that minimizes contamination effects.

Wet grinding predominates in ceramic applications. Grinding in water creates slurries suitable for slip casting, spray drying, or other forming processes. Water also prevents dust, reduces grinding temperatures, and improves grinding efficiency for many ceramic materials.

Paint and Coating Materials

Paint and coating industries require grinding of pigments, fillers, and extenders into extremely fine powders. Particle size directly affects color properties, opacity, gloss, and application characteristics. Many pigments require grinding below 10 microns for optimal performance.

High-energy grinding with small media achieves the extreme fineness required. Ceramic or glass beads in the 1-5mm diameter range provide numerous contact points for intensive grinding action. High-speed agitator mills, a specialized type of grinding equipment, efficiently handle these demanding applications.

Contamination control remains critical as trace contaminants affect color properties. Ceramic, glass, or specialized polymer media prevent metallic contamination. Some applications require complete material compatibility between media, mill components, and processed materials.

Pharmaceutical Applications

Pharmaceutical powder production demands stringent quality control and contamination prevention. Active pharmaceutical ingredients (APIs) often require specific particle size distributions to achieve desired dissolution rates and bioavailability.

Regulatory compliance drives equipment selection and operational practices. Good Manufacturing Practice (GMP) requirements dictate equipment design, material selection, cleaning procedures, and documentation practices. Working with ball mill supplier companies experienced in pharmaceutical applications ensures compliance with regulatory requirements.

Containment systems prevent operator exposure to potent compounds. Closed system designs with contained loading and discharge prevent dust escape. Some applications require processing in inert atmospheres to prevent oxidation or other degradation.

The Role of Experienced Manufacturers

Success in powder production depends significantly on equipment quality and supplier support. Established ball mill manufacturers in india and globally provide expertise that optimizes equipment selection and operational practices.

Engineering and Design Capabilities

Comprehensive engineering support begins with material testing to characterize grinding behavior. Laboratory batch grinding tests establish grindability parameters, predict throughput rates, and optimize operating conditions. This data informs equipment sizing and design decisions.

Process simulation using specialized software predicts full-scale performance based on laboratory data and experience with similar applications. Simulations evaluate alternative configurations, optimize operating parameters, and predict economic performance before capital commitment.

Custom design capabilities address unique requirements that standard equipment cannot meet. Special materials of construction, unusual dimensions, integrated auxiliary systems, or unique operating conditions may require custom engineering. Manufacturing flexibility ensures equipment matches precise application needs.

Quality Manufacturing

Equipment quality directly affects operational reliability and lifespan. Precision fabrication, proper welding procedures, accurate machining, and thorough quality inspection distinguish professional manufacturing from marginal production.

Material selection for critical components affects performance and longevity. Shell materials, liner specifications, bearing designs, drive components, and sealing systems require proper specification and quality materials. Some ball mill machine manufacturers in india source components internationally to ensure quality while maintaining competitive pricing.

Factory testing validates performance before shipment. Test runs verify rotational accuracy, vibration levels, drive system functionality, and overall assembly quality. Documentation of test results provides confidence in equipment condition at delivery.

Comprehensive Support Services

Installation support ensures proper setup and commissioning. Technical supervision during installation prevents errors that compromise performance. Commissioning procedures verify operational parameters and train facility personnel in proper operation and maintenance.

Ongoing technical support addresses operational questions and troubleshooting needs. Access to experienced engineers who understand equipment and applications provides valuable assistance when challenges arise. Some suppliers maintain technical support hotlines staffed by knowledgeable personnel.

Maintenance support programs provide planned maintenance scheduling, spare parts programs, and field service capabilities. Preventive maintenance extends equipment life and prevents unexpected failures. Some operations contract comprehensive maintenance programs where suppliers assume responsibility for equipment availability.

Optimizing Performance and Efficiency

Achieving optimal grinding performance requires attention to operational details and continuous improvement practices.

Process Monitoring and Control

Modern control systems continuously monitor critical parameters including mill load, bearing temperatures, motor power draw, and feed rates. Automated control adjusts feed rates to maintain optimal mill loading, maximizing capacity while preventing overloading.

Product quality monitoring through particle size analysis ensures output meets specifications. Online particle size analyzers provide real-time feedback, enabling rapid response to process variations. Regular sampling and analysis verifies analyzer accuracy and product consistency.

Energy monitoring tracks grinding efficiency and identifies optimization opportunities. Specific energy consumption—energy per ton of material processed—quantifies operational efficiency. Trending this metric over time reveals deteriorating performance requiring corrective action.

Preventive Maintenance

Systematic maintenance programs prevent unexpected failures and extend equipment life. Regular inspections identify wear patterns, developing problems, and component conditions requiring attention. Scheduled maintenance aligns with production schedules to minimize operational disruptions.

Liner management represents a critical maintenance activity. Liner wear monitoring through measurement or visual inspection determines replacement timing. Strategic liner replacement prevents shell damage from worn-through liners while maximizing liner utilization.

Bearing maintenance ensures smooth rotation and prevents costly failures. Lubrication programs follow manufacturer specifications. Vibration monitoring detects developing bearing problems before catastrophic failure. Temperature monitoring provides additional early warning of bearing issues.

Continuous Improvement Practices

Operational data analysis identifies optimization opportunities. Comparing current performance against historical data or industry benchmarks reveals improvement potential. Systematic testing of alternative operating parameters may identify more efficient conditions.

Grinding media management affects both cost and performance. Proper media sizing, regular additions to maintain charge level, and strategic media replacement optimize grinding efficiency. Some operations perform periodic media sorting to remove undersized media while adding larger balls.

Collaboration with ball mill balls suppliers who provide technical support helps optimize media selection and management. Experienced suppliers understand relationships between media properties, application requirements, and grinding performance, providing recommendations that improve results.

Future Trends in Grinding Technology

Grinding technology continues evolving with developments in equipment design, process control, and operational practices.

Advanced Process Control

Artificial intelligence and machine learning applications analyze operational data to optimize parameter settings automatically. These systems learn from historical performance, continuously refining control strategies. Adaptive control adjusts to changing material properties and operating conditions.

Model predictive control uses process models to predict system behavior and optimize control actions. These advanced techniques achieve tighter control than conventional approaches, improving product consistency and energy efficiency.

Energy Efficiency Improvements

Energy consumption represents the largest operational cost for most grinding applications. Ongoing development focuses on improving grinding efficiency through optimized equipment designs, better process control, and improved operating practices.

High-pressure grinding rolls, stirred media mills, and other alternative technologies compete with traditional grinding in some applications. These technologies offer energy advantages for specific applications, though traditional designs retain advantages in reliability, maintenance simplicity, and operational flexibility.

Digitalization and Connectivity

Industrial Internet of Things (IIoT) sensors and connectivity enable remote monitoring and predictive maintenance. Continuous data collection and cloud-based analytics provide insights into equipment condition and performance trends. Predictive maintenance algorithms identify developing problems before failures occur.

Digital twins virtual replicas of physical equipment enable simulation and optimization without disrupting operations. These models predict performance under alternative scenarios, supporting decision-making for process changes or equipment modifications.

Conclusion

The transformation of raw materials into fine powders through ball mill technology represents a well-established yet continually evolving industrial process. Understanding the mechanisms behind particle size reduction, factors affecting grinding performance, and best practices for equipment selection and operation enables industries to optimize their powder production operations.

Success depends on selecting appropriate equipment from experienced ball mill machine manufacturers who understand both the technology and specific application requirements. The growing capabilities of manufacturers, including established ball mill manufacturers in india, provide industries with access to quality equipment supported by comprehensive engineering and service capabilities.

Contact Shalimar Engineering today to get customized rotary kiln solutions designed for your specific production needs and operational requirements.

FAQ

1. What is the primary purpose of a ball mill in industrial powder production?

A ball mill reduces the size of raw materials by applying impact, compression, and attrition forces. This process converts coarse particles into uniform fine powders used across cement, minerals, ceramics, pharmaceuticals, and coatings.

2. How does a ball mill achieve fine powder output?

The rotating cylindrical shell lifts and drops grinding media. As the media moves, it crushes and grinds materials repeatedly. Continuous contact and controlled motion ensure that particles break down to the required fineness.

3. What types of materials can be processed in a ball mill?

Ball mills handle a wide range of materials including minerals, cement clinker, ceramic raw materials, pigments, metal oxides, chemicals, and some pharmaceutical powders. Material suitability depends on hardness, brittleness, and moisture content.

4. How does grinding media size affect the final powder quality?

Larger grinding media generate stronger impacts for breaking coarse particles. Smaller media provide more surface area for fine grinding. A balanced media mix ensures efficient size reduction from start to finish.

5. Why is rotational speed important in ball mill operation?

Rotational speed controls how grinding media moves inside the mill. Operating at 65–80% of critical speed creates optimal cascading action, leading to consistent particle breakdown and improved grinding performance.