Best Iron Ore Manufacturer & Supplier in India

India’s iron ore sector is one of the key drivers of industrial growth, supporting the country’s steel production, construction, and infrastructure development. With the rising demand for steel, efficient processing and utilization of iron ore have become increasingly critical. One of the most effective solutions for this is iron ore pelletization, a process that transforms fine iron ore into high-quality pellets suitable for blast furnaces and direct reduction plants.

Shalimar Engineering, a trusted Iron Ore Pelletization Plant Manufacturer, has been delivering specialized solutions across India. The company offers turnkey pelletizing plants, advanced machinery, and support services that help industries maintain consistent production standards and optimize operational efficiency. This post provides a detailed overview of iron ore pelletization, its benefits, applications, and why partnering with Shalimar Engineering ensures reliable and high-quality output.

Understanding Iron Ore Pelletization

Iron ore pelletization involves the conversion of iron ore fines into uniform, spherical pellets typically ranging from 8–16 millimeters in diameter. These pellets are essential for industrial use because they are easier to handle, reduce dust emissions, and provide superior metallurgical properties compared to raw iron ore fines.

The process starts with iron ore fines, which are carefully blended with binding agents such as bentonite, and sometimes additives like limestone or dolomite, depending on the metallurgical requirements. Water is added to the mixture to form a uniform paste suitable for pellet formation.

Pelletization ensures that industries receive consistent feedstock that improves furnace efficiency, reduces energy consumption, and enhances the overall quality of steel production. High-quality pellets also reduce maintenance issues in furnaces by minimizing clumping and sticking of ore fines.

The Pelletizing Process

The pelletizing process is a multi-step operation that requires precision and high-quality equipment.

First, the prepared raw material is shaped into spherical pellets using balling equipment such as disc pelletizers or drum pelletizers. This stage is critical because uniformity in pellet size and shape affects the strength and quality of the final product.

Once the green pellets are formed, they undergo induration, where they are heated in a furnace at controlled temperatures. Induration strengthens the pellets, providing mechanical stability for handling, storage, and transportation. After firing, the pellets are cooled and screened to separate any oversize or undersize material. Rejected pellets are recycled back into the process to maintain efficiency and reduce waste.

Shalimar Engineering specializes in supplying Ore Pelletizing Equipment that ensures consistent pellet size, optimal energy use, and minimal operational downtime. Their machinery is designed to handle large-scale production while maintaining strict quality standards.

Shalimar Engineering as a Pellet Plant Manufacturer in India

Shalimar Engineering has decades of experience in the field, making it one of the leading Pellet Plant Manufacturers in India. The company delivers complete turnkey solutions, including plant design, equipment supply, installation, and commissioning. Their approach focuses on customization, ensuring that each plant is tailored to the client’s production capacity, material specifications, and operational goals.

The company’s portfolio includes a variety of services:

- Iron Ore Pelletizing Plants: Facilities designed for large-scale industrial production with consistent pellet quality.

- Ore Pelletizing Equipment: High-performance machinery optimized for efficiency, energy savings, and durability.

- Turnkey Pelletizing Plant Solutions: End-to-end services from conceptual planning to operational commissioning.

By choosing Shalimar Engineering, industries benefit from plants designed to deliver optimal output, maintain quality standards, and reduce operational costs. The company ensures that every project meets regulatory compliance and environmental standards, emphasizing sustainable practices in pellet production.

Benefits of Using Iron Ore Pellets

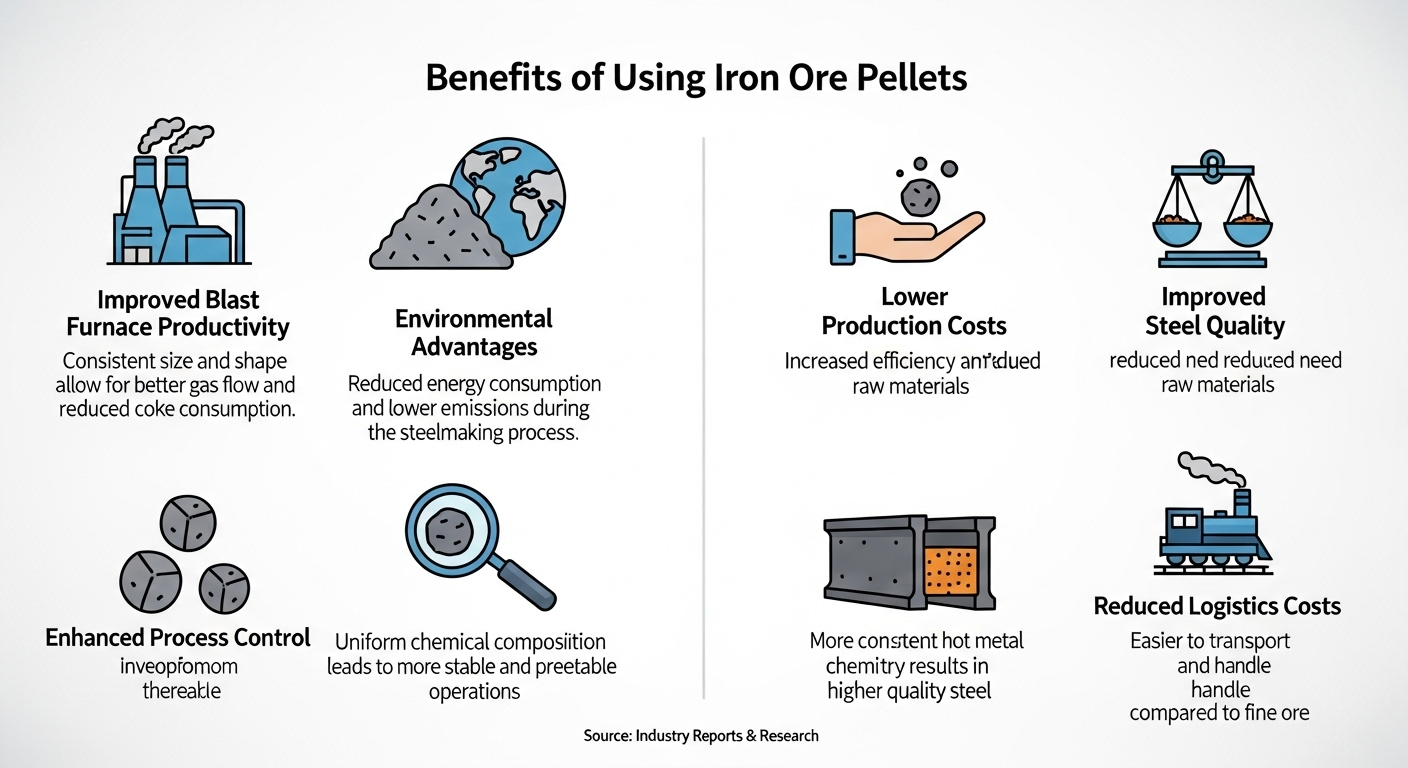

Iron ore pellets offer several advantages over raw fines or lump ore. The consistent size, shape, and chemical composition of pellets improve metallurgical performance, which is critical for efficient steel production. Uniform pellets reduce furnace energy consumption and increase the throughput of blast furnaces and direct reduction plants.

Additionally, pellets are easier to transport and handle, reducing dust generation and minimizing environmental impact. The reduction in operational challenges such as sticking, clumping, or inconsistent feedstock further enhances overall plant productivity. Industries that invest in high-quality Turnkey Iron Pellet Plants enjoy long-term operational stability and cost savings.

Industrial Applications of Iron Ore Pellets

Iron ore pellets are utilized in multiple industrial sectors:

- Steel Manufacturing: Pellets serve as primary feedstock in blast furnaces and direct reduction units, contributing to high-quality steel output.

- Sponge Iron Production: Pelletized iron is used in sponge iron manufacturing plants, providing reliable and uniform input material.

- Construction and Infrastructure: Steel produced from iron ore pellets is essential for construction projects, bridges, and urban infrastructure.

The versatility and efficiency of iron ore pellets make them a preferred choice across industries where consistent quality and reliability are paramount.

Why Shalimar Engineering Stands Out

Shalimar Engineering has emerged as a leading Pelletizing Plant Supplier in India for several reasons. First, their experience in handling turnkey projects ensures that clients receive a complete solution without the need for multiple suppliers. Their team of professionals has expertise in plant design, equipment integration, and process optimization, which guarantees smooth plant operations.

The company’s equipment is designed to deliver high efficiency, lower energy consumption, and minimal maintenance requirements. Customization is a key aspect, as Shalimar Engineering develops plants tailored to client needs, whether for small-scale operations or large industrial setups. Furthermore, their focus on sustainable practices ensures compliance with environmental regulations, reducing the carbon footprint of pellet production.

Features of Shalimar Engineering Pellet Plants

Shalimar Engineering’s plants incorporate several features that enhance productivity and operational reliability:

- Optimized Balling and Firing Processes: Ensures uniform pellet quality.

- Energy-Efficient Design: Reduces power and fuel consumption, lowering operational costs.

- Quality Assurance Checks: Stringent inspections maintain high metallurgical and mechanical standards.

- Maintenance and Support Services: Ensures minimal downtime and prolonged equipment life.

- Scalable Solutions: Plants can be expanded or upgraded as production demand grows.

These features make Shalimar Engineering a preferred partner for companies looking for reliable and efficient pelletizing solutions.

Choosing the Right Pellet Plant Supplier

Selecting the right Iron Ore Pelletization Plant Manufacturer is critical for achieving operational efficiency and long-term profitability. Key factors include:

- Proven experience with turnkey projects.

- Advanced machinery and process expertise.

- Ability to customize plants based on production needs.

- Reliable after-sales support and availability of spare parts.

Shalimar Engineering meets all these requirements, delivering high-quality Ore Pelletizing Equipment and ensuring that plants operate at maximum efficiency from day one.

Future of Iron Ore Pelletization in India

With the expansion of India’s steel and infrastructure sectors, the demand for high-quality iron ore pellets is expected to grow steadily. Industries investing in modern Pellet Plant Manufacturing in India can ensure reliable feedstock, better energy efficiency, and improved production quality.

Shalimar Engineering continues to support this growth by providing advanced turnkey pelletizing plants, incorporating the latest technological advancements and sustainable practices to meet industrial needs.

FAQ – Iron Ore Pelletization and Pellet Plants

Q1: What is an Iron Ore Pelletization Plant?

A1: It is a facility that converts iron ore fines into uniform pellets through balling and induration, suitable for blast furnaces and DRI plants.

Q2: Why are iron ore pellets preferred over fines?

A2: Pellets are uniform in size, easier to handle, reduce dust, and offer better metallurgical properties, improving furnace efficiency.

Q3: What services does Shalimar Engineering provide?

A3: The company provides turnkey pelletizing plants, Ore Pelletizing Equipment, plant design, installation, commissioning, and maintenance support.

Q4: Can the plants be customized?

A4: Yes, Shalimar Engineering designs each plant to match production capacity, material specifications, and operational requirements.

Q5: What is the advantage of turnkey pellet plants?

A5: Turnkey plants reduce setup time, ensure compatibility of equipment, and offer a complete operational solution from start to finish.

Conclusion

Iron ore pelletization is essential for modern steel production and industrial applications. High-quality pellets improve furnace efficiency, reduce operational challenges, and enhance metallurgical performance. Partnering with a reliable Pelletizing Plant Supplier in India like Shalimar Engineering ensures that plants deliver consistent results, minimize operational costs, and adhere to quality and environmental standards.

For industries seeking a dependable Iron Ore Pelletization Plant Manufacturer, Shalimar Engineering offers the expertise, experience, and complete turnkey solutions required for long-term success.

Contact Shalimar Engineering Today to discuss your project requirements and to arrange a consultation.