Industrial Roller Crushers: Essential Equipment for Efficient Material Processing

Industrial crushing equipment plays a vital role in mining, cement, metallurgy, power generation, and recycling industries. Among the wide range of machines used for material processing, the roll crusher machine stands out as one of the mo st efficient and versatile options. It is designed to compress and crush raw materials into manageable sizes, ensuring uniformity and smooth operations across industrial workflows.

Choosing the right roller crusher manufacturer is critical to ensuring high performance, durability, and efficiency. With technological advancements and growing demand, modern roller crusher manufacturers in Ahmedabad and across India are offering innovative solutions tailored for various industrial needs.

This guide explores everything about industrial roller crushers—from working principles and industrial applications to selecting the right manufacturer and understanding future trends.

Understanding Roller Crushers and Their Mechanism

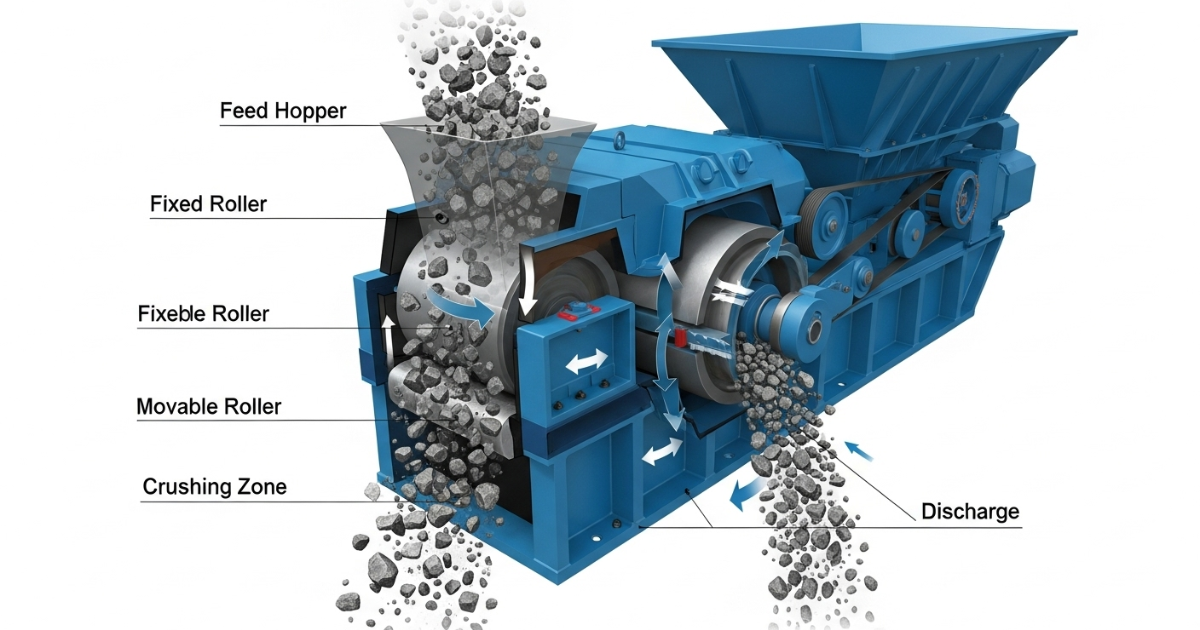

A roll crusher machine operates by compressing materials between two rotating rollers. As the raw materials pass through the gap, they are crushed into smaller pieces, producing a consistent particle size suitable for further processing.

Key features of roller crushers include:

- Uniform crushing: Ensures consistent material size and reduces the need for secondary crushing.

- Energy efficiency: Advanced designs minimize power consumption while maximizing output.

- Durability: High-strength rollers withstand abrasive and hard materials.

- Low maintenance: Modular designs and wear-resistant materials reduce downtime.

The performance of a roller crusher depends heavily on the quality of the machine and the expertise of the roller crusher manufacturer. Modern manufacturers integrate technologies like automation, IoT monitoring, and energy-efficient designs to enhance productivity.

Industrial Applications of Roller Crushers

Mining and Minerals

In mining operations, roll crusher machines are widely used to crush ores, metallic minerals, and stones. They are capable of handling hard and abrasive materials while providing consistent output, making them indispensable in mining workflows.

Cement Industry

Cement production requires processing limestone and clinker efficiently. Roller crusher machines reduce raw materials to precise sizes, ensuring better kiln feeding and optimal energy consumption. Crusher manufacturers in India offer tailored solutions that meet the unique requirements of cement plants.

Coal Processing

Coal plants use roll crusher machines to size coal for combustion or further processing. Efficient crushing ensures uniform particle size, which is critical for thermal efficiency and power generation.

Recycling and Waste Management

Industries focused on recycling use roller crushers to process construction debris, glass, plastics, and industrial waste. Modern roller crusher manufacturers in Ahmedabad provide machines that handle diverse materials while maintaining high throughput and low energy consumption.

Chemical Industry

Chemical processing industries require precise crushing of raw chemicals and minerals. Roller crushers provide uniform particle size, reducing variability in chemical reactions and ensuring product consistency.

Key Considerations When Choosing a Roller Crusher Manufacturer

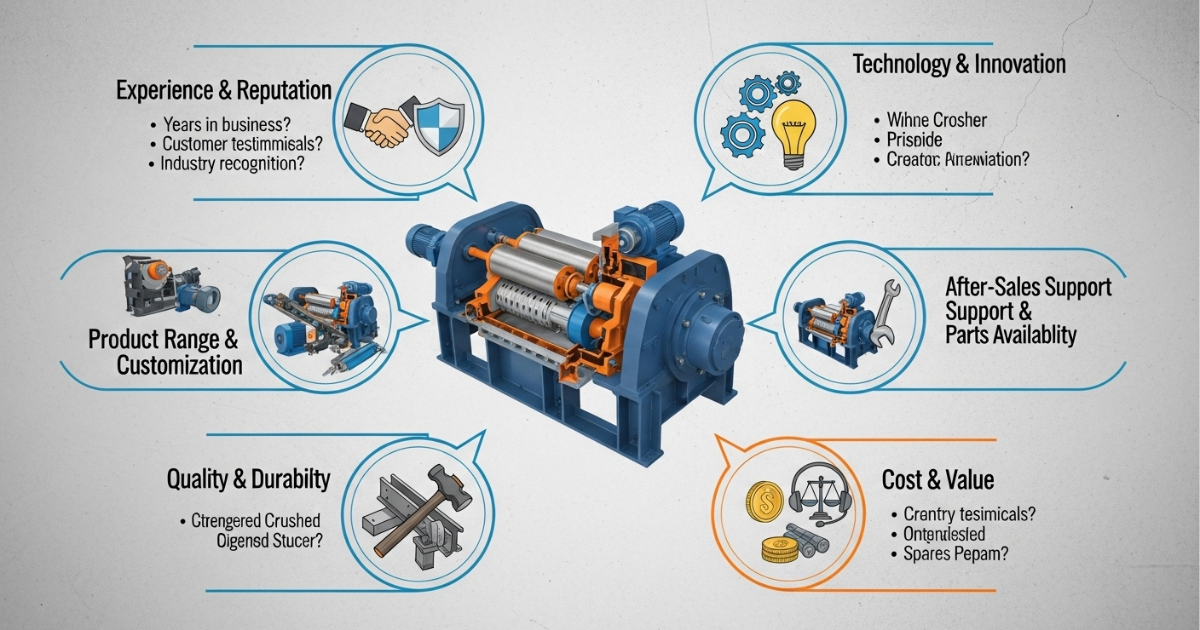

Industry Experience and Reputation

A manufacturer’s credibility plays a crucial role in long-term operational success. Experienced crusher manufacturers in India have in-depth knowledge of material handling and industrial requirements, producing roll crusher machines that meet diverse challenges.

Product Quality and Engineering Standards

High-quality materials and precision engineering ensure durability and performance. Leading roller crusher manufacturers in Ahmedabad use wear-resistant alloys and surface-hardened rollers to enhance machine lifespan, reduce maintenance, and provide uniform output.

Customization and Flexibility

Industries often have unique operational requirements. Manufacturers offering customized roll crusher machines ensure that the equipment integrates seamlessly into existing systems. Adjustable roller gaps, variable speed controls, and automation compatibility are examples of customization options.

Technological Advancements

Modern roller crusher manufacturers are adopting Industry 4.0 technologies. Smart sensors, IoT-enabled monitoring, predictive maintenance, and energy-efficient designs optimize operations, reduce energy costs, and ensure consistent output.

After-Sales Service and Support

Reliable manufacturers provide comprehensive after-sales support, including spare parts, technical assistance, and maintenance guidance. Roller crusher manufacturers in Ahmedabad often maintain service teams across major industrial zones, ensuring minimal downtime and smooth operations.

Cost and Value Optimization

Industries should focus on total cost of ownership rather than upfront price. Investing in a high-quality roll crusher machine may involve a higher initial cost but leads to long-term savings through reduced energy consumption, minimal maintenance, and improved productivity.

Safety and Environmental Compliance

Modern roller crushers incorporate dust suppression, noise reduction, and energy-efficient designs. Compliance with international safety and environmental standards ensures a safer working environment while supporting sustainability goals.

Advantages of Indian Roller Crusher Manufacturers

- Competitive pricing without compromising quality

- Fast and reliable after-sales support

- Advanced engineering and IoT integration

- Flexibility for customization and industry-specific solutions

- Adherence to international safety and quality standards

India, particularly regions like Gujarat, Maharashtra, and Tamil Nadu, has emerged as a global hub for industrial machinery, with roller crusher manufacturers in Ahmedabad delivering innovative and reliable machines to both domestic and international clients.

Common Challenges in Roller Crusher Operations

- Frequent breakdowns due to poor-quality machines

- Inconsistent particle size affecting production processes

- High energy consumption and operational costs

- Limited service and spare part availability from unreliable manufacturers

Partnering with reputable crusher manufacturers in India addresses these challenges, ensuring smooth operations and long-term reliability.

Best Practices for Selecting the Right Manufacturer

- Evaluate the manufacturer’s experience and track record in your industry.

- Assess the quality of materials, rollers, and engineering standards.

- Check for customization options to meet specific operational needs.

- Review technological capabilities, such as automation, IoT, and energy efficiency.

- Ensure strong after-sales support, spare part availability, and maintenance services.

- Compare costs based on total value and lifecycle benefits rather than upfront price.

- Verify safety and environmental compliance to meet modern industrial standards.

Following these practices ensures a high-quality investment in a roll crusher machine that delivers consistent results.

Future Trends in Roller Crusher Manufacturing

- IoT and Smart Monitoring: Real-time performance analysis improves operational efficiency.

- Predictive Maintenance: AI-based maintenance reduces downtime and extends equipment life.

- Energy Efficiency: Machines are being designed to consume less power per ton of material processed.

- Wear-Resistant Materials: Advanced alloys enhance durability and reduce maintenance frequency.

- Sustainability Initiatives: Eco-friendly designs and alternative fuel integration reduce environmental impact.

These innovations from roller crusher manufacturers in Ahmedabad and other leading industrial regions position India as a global leader in industrial crushing equipment.

Conclusion

Selecting the right roller crusher manufacturer is a strategic decision that influences industrial efficiency, sustainability, and overall profitability. Modern roll crusher machines are designed to optimize energy consumption, deliver consistent output, and handle a wide variety of materials efficiently.

With trusted crusher manufacturers in India, particularly roller crusher manufacturers in Ahmedabad, industries gain access to innovative, reliable, and cost-effective solutions. By focusing on quality, technology, customization, and strong support services, businesses can maximize productivity, reduce operational costs, and achieve long-term growth.