Selecting the right drying equipment can significantly impact your production efficiency and operational costs. When it comes to handling bulk materials that require consistent moisture removal, a Rotary Dryer stands out as one of the most reliable solutions available in the industrial sector. However, the performance and longevity of this equipment largely depend on the manufacturer’s expertise and commitment to quality.

Understanding the Importance of Quality Rotary Dryer Systems

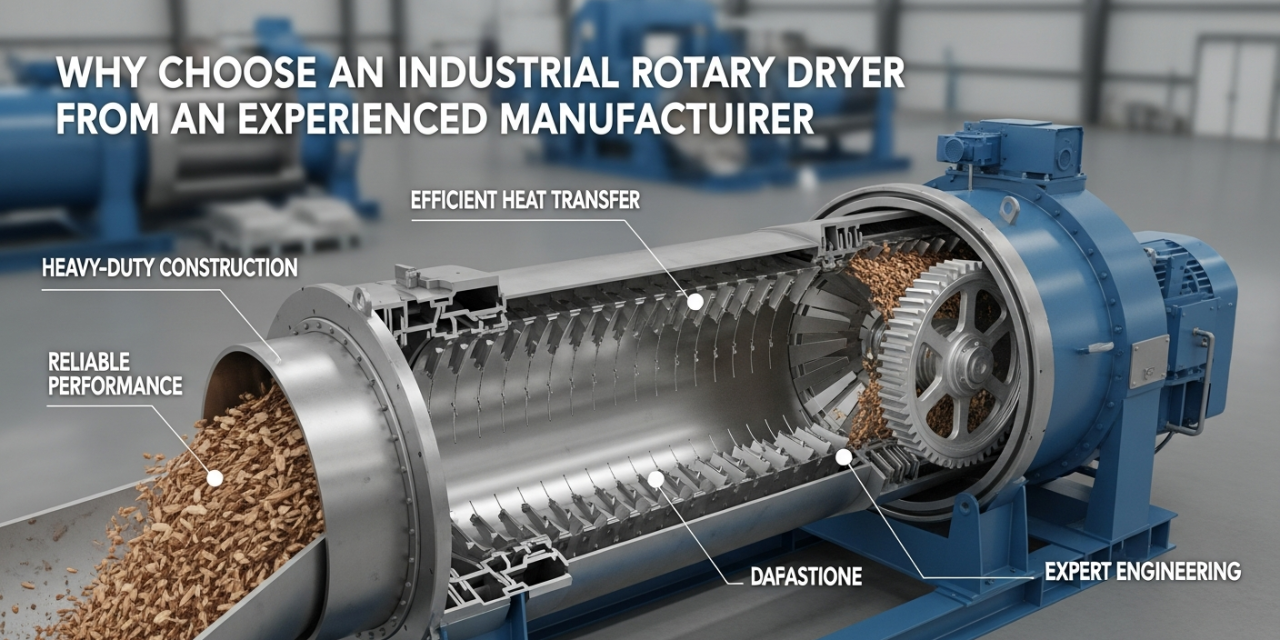

A rotary dryer is a thermal processing unit designed to reduce moisture content in various materials through direct or indirect heat transfer. These cylindrical vessels rotate continuously, ensuring uniform heat distribution and consistent drying results across different material types. Industries ranging from minerals processing to chemical production rely on these systems for their material handling needs.

The choice of manufacturer matters because not all drying systems are built with the same engineering standards. Working with established rotary dryer manufacturers means accessing decades of research, field-tested designs, and proven performance records that newer market entrants simply cannot match.

Key Advantages of Working with Experienced Manufacturers

Proven Engineering Excellence

When you partner with seasoned rotary dryer suppliers, you gain access to equipment that has been refined through years of real-world application. Shalimar Engineering brings extensive experience in designing and manufacturing drying equipment that meets diverse industrial requirements. This experience translates into systems that operate efficiently under varying load conditions and material characteristics.

Experienced manufacturers understand the nuances of heat transfer dynamics, material flow patterns, and structural integrity requirements that ensure long-term operational reliability. This knowledge base allows them to create equipment that performs consistently while minimizing maintenance requirements.

Customization Based on Application Requirements

Every industrial process has unique requirements. Material properties, desired moisture levels, production capacity, and available space all influence the ideal dryer configuration. Established manufacturers offer customization options that address these specific needs rather than providing one-size-fits-all solutions.

Whether you’re processing minerals, chemicals, agricultural products, or industrial waste, an industrial rotary dryer from an experienced manufacturer can be tailored to match your exact specifications. This includes adjustments to drum dimensions, flight configurations, heat source integration, and material handling systems.

Superior Build Quality and Material Selection

The durability of drying equipment directly correlates with the quality of materials used in construction. Reputable Rotary Dryer Manufacturers invest in high-grade steel, corrosion-resistant coatings, and precision-engineered components that withstand harsh operating environments.

Shalimar Engineering’s commitment to quality means each rotary dryer is constructed to handle thermal stress, abrasive materials, and continuous operation without premature wear. This attention to material selection and fabrication standards results in equipment that delivers reliable performance year after year.

Talk to Our Experts and Get the Right Industrial Solution Today

Technical Features That Define Quality Equipment

Efficient Heat Transfer Design

The effectiveness of any drying system depends on its ability to transfer heat efficiently to the material being processed. Quality manufacturers incorporate features like optimized flight patterns, proper drum inclination angles, and strategic inlet/outlet configurations that maximize contact time between material and heated air.

These design elements ensure that your industrial rotary dryer operates at peak thermal efficiency, reducing energy consumption while maintaining consistent output quality. The result is lower operational costs and improved profitability.

Robust Drive Systems and Control Mechanisms

Continuous rotation under heavy loads requires dependable drive systems. Experienced manufacturers specify appropriately sized motors, gearboxes, and support structures that handle operational demands without excessive wear. Additionally, modern control systems allow operators to adjust rotation speed, temperature settings, and feed rates to optimize performance for different materials.

Safety and Environmental Considerations

Professional rotary dryer suppliers prioritize safety features and environmental compliance in their designs. This includes proper sealing systems to contain dust emissions, temperature monitoring devices to prevent overheating, and emergency shutdown mechanisms that protect both equipment and personnel.

Long-Term Value Proposition

Reduced Total Cost of Ownership

While initial equipment cost matters, the total cost of ownership over the system’s lifespan provides a more accurate measure of value. Equipment from experienced manufacturers typically requires less frequent repairs, operates more efficiently, and maintains performance levels longer than lower-quality alternatives.

This reliability translates into reduced downtime, lower maintenance expenses, and consistent production output that protects your bottom line.

Comprehensive Support and Service

Established manufacturers stand behind their products with comprehensive support services. From installation assistance to operator training, technical troubleshooting, and spare parts availability, this ongoing support ensures your Rotary Dryer continues operating at optimal levels throughout its service life.

Shalimar Engineering provides dedicated after-sales support that helps customers address operational challenges quickly and effectively, minimizing production interruptions.

Scalability and Future Expansion

As your business grows, your drying capacity requirements may change. Working with experienced manufacturers who understand market demands and technological advancements means you have partners who can help you scale operations efficiently. Whether through capacity upgrades, process improvements, or integration of complementary equipment, this partnership approach supports your long-term growth objectives.

Making the Right Selection Decision

Choosing drying equipment represents a significant capital investment that impacts your operations for years to come. The manufacturer you select should demonstrate technical competence, quality commitment, and customer support capabilities that align with your business needs.

Consider factors beyond initial price, including equipment specifications, manufacturer reputation, support infrastructure, and the ability to provide customized solutions. Request detailed technical documentation, reference installations, and performance guarantees that give you confidence in your investment.

An industrial rotary dryer from a manufacturer with proven expertise provides the reliability, efficiency, and longevity that modern industrial operations demand. By partnering with Shalimar Engineering, you gain access to equipment designed with precision, built to last, and supported by a team committed to your operational success.

Conclusion

The decision to invest in drying equipment should be made with careful consideration of both immediate needs and long-term operational goals. Working with experienced rotary dryer manufacturers like Shalimar Engineering ensures you receive equipment that meets rigorous quality standards while providing the performance reliability your business requires.

Quality manufacturing, application-specific customization, and comprehensive support services combine to deliver value that extends far beyond the initial purchase. When your production depends on consistent moisture removal and operational reliability, choosing the right manufacturer makes all the difference.

For businesses seeking dependable drying solutions backed by engineering excellence and proven performance, exploring options from established rotary dryer suppliers represents a strategic investment in operational efficiency and long-term success.

Talk to Our Experts and Get the Right Industrial Solution Today

Frequently Asked Questions (FAQs)

1. Why should I choose an industrial rotary dryer from an experienced manufacturer?

An experienced manufacturer offers proven designs, application-specific engineering, superior build quality, and long-term support. This ensures reliable performance, lower maintenance costs, and extended equipment life compared to generic or inexperienced suppliers.

2. What makes industrial rotary dryers suitable for bulk material drying?

Industrial rotary dryers provide continuous operation, uniform heat distribution, and high throughput. Their rotating drum and internal flight design ensure consistent moisture removal across a wide range of materials.

3. Can an industrial rotary dryer be customized for my application?

Yes, experienced rotary dryer manufacturers customize drum size, flight configuration, heating method, rotation speed, and control systems based on material properties, capacity requirements, and site conditions.

4. What industries benefit most from industrial rotary dryers?

Industries such as mining, mineral processing, chemical manufacturing, agriculture, food processing, biomass, and industrial waste treatment widely use industrial rotary dryers for efficient moisture control.

5. How does build quality impact rotary dryer performance?

High-quality materials and precision fabrication help rotary dryers withstand thermal stress, abrasion, and continuous operation. Superior build quality reduces breakdowns, improves energy efficiency, and extends service life.