Industrial operations across the globe require reliable drying solutions to maintain production efficiency and product quality. The rotary dryer stands as the most dependable equipment for bulk material moisture reduction, serving industries from mining to food processing. Finding qualified rotary dryer suppliers who understand your specific application requirements makes the difference between operational success and costly setbacks.

Understanding Industrial Rotary Dryer Systems

A Rotary Dryer operates as a rotating cylindrical vessel designed to remove moisture from materials through controlled heat application. The drum rotates at a slight angle, using gravity to move materials from the feed end toward discharge while internal flights lift and cascade the material through hot gases.

This fundamental design has proven effective across countless applications because it provides continuous processing, uniform moisture removal, and adaptability to different materials. The industrial rotary dryer handles everything from abrasive minerals to temperature-sensitive chemicals, making it indispensable in modern manufacturing.

The key to effective drying lies in maximizing contact between materials and the drying medium. As the drum rotates, specially designed flights scoop material and shower it through heated air or gases. This repeated lifting and cascading action exposes every particle to the drying environment, ensuring consistent moisture reduction throughout the batch.

Critical Components That Define Quality

When evaluating Rotary Dryer Suppliers, understanding component quality helps distinguish reliable equipment from problematic installations:

Drum Construction: The main cylinder must withstand thermal stress, material abrasion, and continuous rotation. Quality suppliers use appropriate steel grades—carbon steel for standard applications, stainless steel for corrosive materials, and special alloys for extreme temperatures. Proper thickness and welding procedures ensure structural integrity over decades of operation.

Support and Drive Systems: Heavy-duty riding rings, precision-machined trunnion wheels, and robust support structures carry the loaded drum while maintaining proper alignment. Drive systems include properly sized motors, reduction gearboxes, and drive mechanisms that provide smooth, controlled rotation without excessive wear.

Internal Flights: These critical components determine drying efficiency. Flight design varies based on material characteristics—deeper flights for free-flowing materials, shallower configurations for sticky products, specialized patterns for specific applications. Quality fabrication and secure attachment prevent premature failure.

Sealing Systems: Effective seals at drum ends prevent air infiltration that wastes energy and reduces efficiency. Advanced sealing designs accommodate thermal expansion while maintaining tight clearances. Poor seals significantly increase operating costs through wasted fuel.

Heating Equipment: Whether using direct-fired burners, steam systems, or thermal oil heaters, the heat source must provide consistent, controllable energy. Integration with the drying system affects both efficiency and product quality.

Talk to Our Experts and Get the Right Industrial Solution Today

How Material Properties Influence Dryer Selection

Successful Rotary Dryer applications begin with understanding material characteristics:

Moisture Content: Initial moisture ranging from 5% to 60% affects residence time requirements and heating capacity. Materials with higher initial moisture need longer drying times or higher temperatures.

Particle Size: Fine powders below 100 microns require different flight configurations and air velocities compared to coarse materials exceeding 10 millimeters. Particle size distribution throughout processing must be considered.

Temperature Sensitivity: Heat-sensitive materials like certain chemicals or food products require careful temperature control to prevent degradation. This influences heating method selection and control system requirements.

Stickiness: Materials that become sticky when heated need specialized flight designs and may require conditioning agents or modified operating parameters to prevent buildup on drum surfaces.

Abrasiveness: Highly abrasive materials like silica sand or certain minerals demand heavier construction, wear-resistant materials, and more frequent maintenance intervals.

Experienced rotary dryer suppliers evaluate these properties to recommend appropriate equipment specifications rather than offering one-size-fits-all solutions.

Applications Across Global Industries

Mining and Mineral Processing

Mining operations worldwide depend on rotary dryer technology for processing iron ore, copper concentrates, gold ore, coal, and numerous other minerals. Moisture reduction before transportation cuts shipping costs substantially while preventing material caking during storage. Large-scale operations process hundreds of tons per hour, requiring robust equipment designed for continuous operation in demanding environments.

Chemical Production

Chemical manufacturers require precise moisture control for products including fertilizers, pigments, catalysts, and specialty chemicals. The industrial rotary dryer provides the temperature control and material handling needed for sensitive compounds. Stainless steel construction and specialized sealing prevent contamination while meeting strict quality standards.

Agricultural and Food Industries

Grain drying, animal feed production, biomass processing, and specialty crops all utilize rotary drying technology. Food-grade construction, careful temperature management, and hygienic design principles ensure products meet safety regulations while maintaining nutritional value. From corn and soybeans to coffee and nuts, proper drying prevents spoilage and extends shelf life.

Environmental and Waste Processing

Municipal wastewater treatment facilities use rotary dryers for biosolids volume reduction, converting wet sludge into dry pellets suitable for disposal or beneficial reuse. Industrial waste streams, contaminated soils, and hazardous materials often require thermal treatment in rotary systems designed for safe handling and emissions control.

Key Performance Factors to Consider

Processing Capacity: Throughput requirements determine drum dimensions and heating capacity. Underestimating needs creates production bottlenecks, while overdesigning wastes capital and increases operating costs. Qualified Rotary Dryer Suppliers size equipment based on actual material properties and production requirements, not just theoretical calculations.

Energy Efficiency: Fuel costs represent a major operational expense. Modern designs incorporate improved insulation, advanced sealing, and heat recovery systems that can reduce consumption by 30-40%. Some applications benefit from waste heat utilization or combined heat and power systems.

Moisture Removal Rate: The difference between inlet and outlet moisture content, combined with throughput, determines drying capacity. Achieving target moisture levels consistently requires proper residence time, adequate heating, and effective material-gas contact.

Operational Reliability: Equipment downtime disrupts production and costs money. Reliable industrial rotary dryer systems feature robust construction, quality components, and maintainable designs that minimize failures and simplify repairs when needed.

Environmental Compliance: Emission regulations continue tightening worldwide. Modern systems include dust collection, gas treatment, and monitoring equipment to meet regulatory requirements. Choosing suppliers familiar with relevant standards ensures compliant installations.

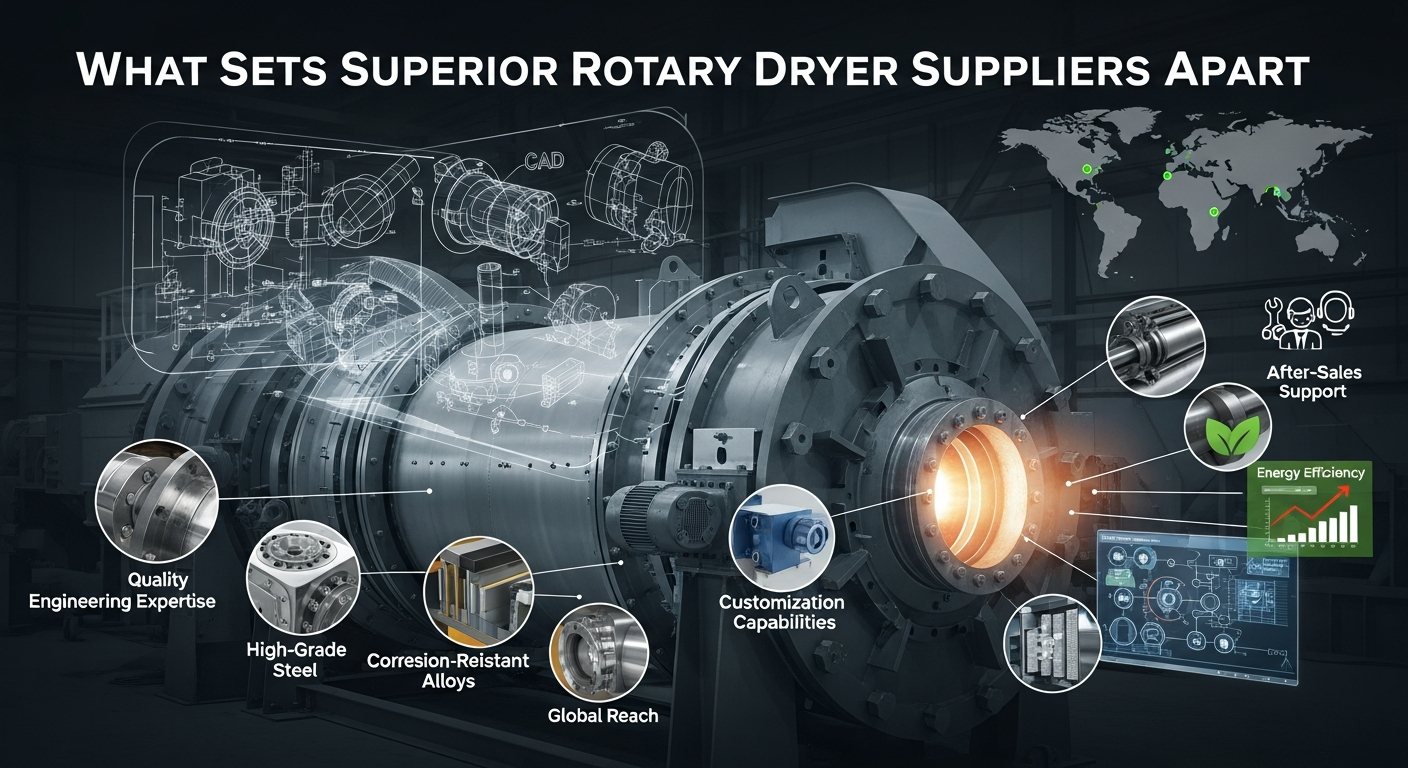

What Sets Superior Rotary Dryer Suppliers Apart

Engineering Expertise: The best rotary dryer suppliers employ experienced engineers who understand material behavior, heat transfer principles, and practical operational considerations. This expertise translates into optimized designs that perform as promised.

Custom Design Capabilities: While standard designs work for common applications, many situations require modifications. Flexible engineering approaches adapt equipment to unique materials, capacity requirements, space constraints, or special handling needs.

Manufacturing Quality: Precision fabrication, certified welding procedures, quality materials, and thorough inspections separate reliable equipment from troublesome installations. Requesting manufacturing facility tours and quality documentation reveals supplier capabilities.

Testing and Validation: Reputable suppliers test equipment before shipment, verifying mechanical operation, heating uniformity, and control system functionality. Some offer pilot testing with customer materials to validate performance predictions.

Installation Support: Proper installation requires expertise. Comprehensive support including foundation specifications, installation supervision, and commissioning assistance ensures successful startup. Poor installation undermines even the best equipment.

Training Programs: Operators need to understand equipment operation, routine maintenance, and troubleshooting. Thorough training programs improve operational efficiency while reducing maintenance costs and extending equipment life.

Ongoing Technical Support: Questions and issues arise during operation. Accessible technical support from knowledgeable personnel helps resolve problems quickly, minimizing production disruptions.

Spare Parts Availability: Critical components eventually wear out. Suppliers maintaining adequate spare parts inventory minimize downtime during repairs or scheduled maintenance.

Maintenance Requirements for Long-Term Success

Reliable operation requires consistent maintenance attention:

Daily Operations: Monitor bearing temperatures, observe material flow patterns, listen for unusual sounds, check seal condition, verify control system readings.

Weekly Tasks: Inspect internal flights for wear or damage, examine seals for air leakage, verify drive system alignment and tension, test safety interlocks.

Monthly Procedures: Lubricate bearings and drive components, inspect structural supports, review operational data for performance trends, clean dust collection systems.

Quarterly Reviews: Detailed inspection of drum shell integrity, measurement of flight wear, examination of refractory or insulation condition, calibration verification.

Annual Overhaul: Comprehensive inspection of all mechanical and electrical systems, replacement of worn components, testing of safety systems, performance verification.

Following manufacturer maintenance schedules maximizes equipment reliability while minimizing lifecycle costs.

Technology Advancements Improving Performance

Modern rotary dryer systems incorporate technological improvements:

Advanced Controls: Programmable logic controllers with touchscreen interfaces enable precise parameter monitoring and automatic adjustments. Data logging supports quality documentation and troubleshooting.

Heat Recovery: Waste heat capture systems preheat combustion air or generate steam, reducing fuel consumption significantly. Some designs achieve 80%+ thermal efficiency.

Variable Frequency Drives: Electronic speed control optimizes rotation for different materials and operating conditions while reducing energy consumption during startup and light loads.

Emission Controls: Sophisticated dust collection, gas scrubbing, and monitoring systems meet increasingly stringent environmental regulations worldwide.

Predictive Maintenance: Vibration monitoring, bearing temperature tracking, and performance analysis enable early detection of developing problems before failures occur.

Why Shalimar Engineering Leads the Industry

As trusted rotary dryer suppliers, Shalimar Engineering combines decades of experience with modern engineering capabilities:

Application Knowledge: Extensive experience across mining, chemical, agricultural, and environmental applications enables accurate equipment recommendations and reliable performance predictions.

Custom Engineering: Flexible design approach addresses unique requirements, space limitations, and special handling needs through proven modifications.

Quality Manufacturing: Premium materials, certified fabrication procedures, and thorough quality inspections ensure equipment meets demanding performance standards.

Global Experience: Successful installations worldwide demonstrate capability with diverse materials, regulatory environments, and operational conditions.

Comprehensive Support: From initial consultation through installation, commissioning, and ongoing operation, providing technical expertise that ensures project success.

Performance Commitment: Confidence in equipment quality backed by warranties and dedication to customer satisfaction throughout equipment lifecycle.

Conclusion

Selecting qualified rotary dryer suppliers represents a critical decision affecting operational efficiency, product quality, and long-term costs. The industrial rotary dryer remains the preferred solution for bulk material drying across diverse industries worldwide, but equipment quality and supplier capabilities vary significantly.

Shalimar Engineering’s rotary dryer solutions combine proven technology with custom engineering, reliable manufacturing, and comprehensive support. Whether processing minerals, chemicals, agricultural products, or industrial waste, their systems deliver the performance modern operations require.

Partnering with experienced rotary dryer suppliers ensures your operation receives properly designed equipment, professional installation, thorough training, and ongoing support all essential elements for long-term success in today’s competitive industrial environment.

Talk to Our Experts and Get the Right Industrial Solution Today

Frequently Asked Questions (FAQs)

1. What do rotary dryer suppliers provide?

Rotary dryer suppliers design, manufacture, and supply industrial rotary drying systems used to remove moisture from bulk materials. Their services often include engineering consultation, customization, installation support, commissioning, and after-sales service.

2. Which industries rely on industrial rotary dryers?

Industrial rotary dryers are widely used in mining and mineral processing, chemical manufacturing, agriculture and food processing, biomass, fertilizer production, and environmental waste management applications.

3. How do rotary dryer suppliers customize equipment for different materials?

Experienced suppliers analyze material properties such as moisture content, particle size, abrasiveness, and temperature sensitivity. Based on this data, they customize drum size, flight design, heating method, rotation speed, and control systems for optimal performance.

4. What factors should I consider when choosing rotary dryer suppliers?

Key factors include engineering expertise, customization capability, manufacturing quality, testing and validation processes, installation support, spare parts availability, and long-term technical support.

5. What is the typical capacity range of industrial rotary dryers?

Industrial rotary dryers can handle capacities ranging from a few hundred kilograms per hour to over 100 tons per hour, depending on material characteristics and system design.