Top Rotary Dryer Manufacturers and Suppliers in India

India has established itself as a hub for industrial equipment manufacturing, providing world-class engineering solutions across diverse industries. Among these essential machines, the Rotary Dryer holds a critical place in industrial processes that require moisture removal from bulk solids. From minerals and fertilizers to chemicals and food processing, the demand for reliable and efficient drying systems continues to rise. Consequently, the search for the top rotary dryer manufacturer in the country has become a key focus for industries looking to enhance operational performance, reliability, and efficiency.

The Indian market features several reputed Rotary Dryer Manufacturers in India known for their technical expertise, innovation, and ability to deliver customized solutions. In states like Gujarat and cities like Ahmedabad, manufacturers such as Shalimar Engineering have gained recognition for providing durable and high-performance rotary dryers designed for industrial excellence. These manufacturers cater to both domestic and international markets, making India one of the most competitive and reliable destinations for drying equipment manufacturing.

Understanding Rotary Dryers and Their Importance

A Rotary Dryer is an industrial machine designed to reduce moisture content in solid materials. It operates by passing heated air or gas through a rotating cylindrical drum that tumbles the material, ensuring uniform drying. This continuous rotation facilitates even heat distribution, making rotary dryers suitable for handling a wide range of materials including ores, fertilizers, chemicals, and food products.

The Industrial Rotary Dryer has become indispensable for industries that require consistent drying efficiency. Unlike other drying systems, rotary dryers offer scalability, energy efficiency, and versatility. They are particularly preferred in industries where moisture control directly impacts product quality, process performance, or shelf life. The reliability of these machines depends greatly on the quality of engineering and materials used by the rotary dryer manufacturer.

The Growth of Rotary Dryer Manufacturers in India

Over the last few decades, India has emerged as a leading center for industrial machinery production. The rotary dryer manufacturers in India have continually advanced their technology, focusing on energy-efficient designs, superior materials, and customizable configurations. Gujarat, in particular, has become one of the strongest industrial bases for equipment manufacturing.

The rise in industrialization, coupled with the growing demand for sustainable and cost-efficient machinery, has driven the development of advanced rotary dryers. Indian manufacturers have responded by integrating automation, precision engineering, and material optimization into their production processes. As a result, Rotary Dryer Manufacturers in Gujarat and rotary dryer manufacturers in Ahmedabad are not only meeting domestic needs but also serving global industries through exports.

What Sets Indian Rotary Dryer Manufacturers Apart

The strength of Rotary Dryer Suppliers in India lies in their focus on engineering excellence, customization, and after-sales support. Manufacturers understand that different industries have distinct requirements for drying systems. Whether it’s high-temperature mineral processing or delicate food drying, Indian manufacturers tailor their designs to meet performance and material needs.

Moreover, the growing emphasis on sustainability has led manufacturers to design energy-efficient dryers with optimized airflow and heat recovery mechanisms. This ensures lower operational costs and reduced environmental impact. The commitment to innovation, coupled with decades of industrial experience, positions Indian manufacturers among the most trusted Rotary Dryer Exporters globally.

Features and Advantages of Indian Rotary Dryers

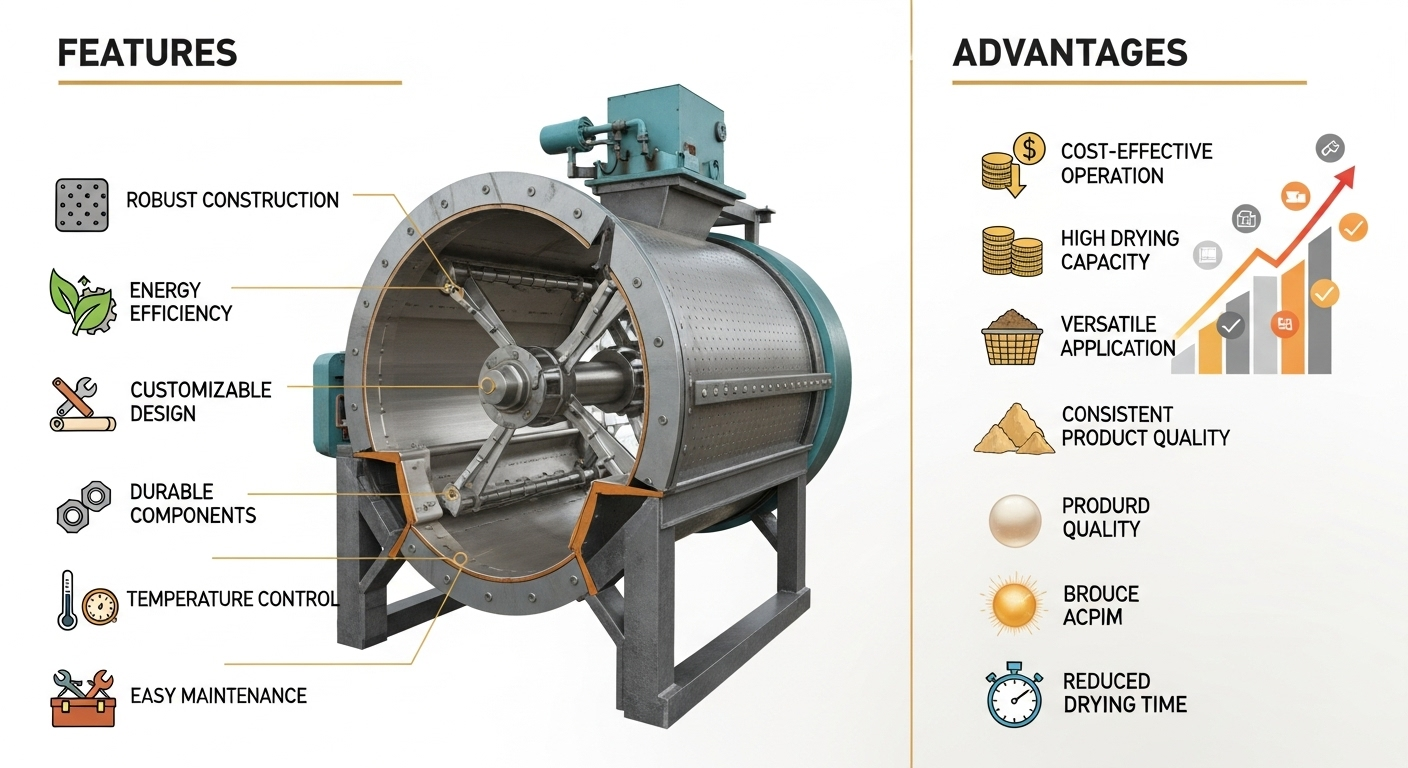

The quality of an Industrial Rotary Dryer depends on the precision of its design, choice of materials, and manufacturing expertise. Indian manufacturers incorporate robust construction, efficient airflow design, and advanced heat transfer systems to deliver long-lasting and high-performing machines.

Here are some features and advantages commonly found in rotary dryers produced by leading Indian manufacturers like Shalimar Engineering:

- Durable Construction: Use of high-grade steel and wear-resistant liners ensures longevity and consistent operation under high temperatures.

- Energy Efficiency: Optimized designs minimize heat loss and improve fuel utilization.

- Custom Configuration: Tailored drum sizes, heating systems, and rotational speeds for different materials and industries.

- Ease of Maintenance: Modular components and accessible design allow quick servicing and reduced downtime.

- Versatility: Suitable for a wide range of applications including minerals, fertilizers, chemicals, biomass, and food products.

These features collectively demonstrate why industries prefer Indian-made rotary dryers that combine innovation with reliability.

Applications Across Industries

The versatility of Rotary Dryers has made them essential across numerous industries. In the mineral industry, rotary dryers are used to dry ores, sand, and clay before processing. The chemical industry relies on them for precise moisture control to maintain product quality. In fertilizer plants, rotary dryers ensure consistent drying of materials such as urea and ammonium nitrate for optimal storage and packaging.

Similarly, the food industry benefits from rotary dryers for drying grains, starches, and powders, maintaining uniform quality without overheating. In waste management, these machines are used for drying sludge, biomass, and organic waste, making it easier to handle and dispose of. The ability to adapt to multiple industrial needs is one of the reasons Indian Rotary Dryer Manufacturers in India are in such high demand.

The Role of Customization in Rotary Dryer Manufacturing

Every industrial process has unique drying parameters depending on material type, moisture content, and operational scale. Reputed Rotary Dryer Manufacturers in India emphasize the importance of customization to ensure efficiency and productivity. Manufacturers like Shalimar Engineering work closely with clients to design dryers that match specific industrial needs.

Customization can involve selecting suitable drum sizes, determining air temperature, adjusting residence time, and choosing between direct or indirect heating methods. The end result is a system that ensures optimal drying with minimal energy consumption. The flexibility to adapt designs and specifications gives Indian manufacturers a significant edge over standardized international competitors.

Choosing the Right Rotary Dryer Manufacturer

Selecting the ideal rotary dryer manufacturer in India requires careful consideration of several factors, including manufacturing experience, technical expertise, after-sales service, and the quality of materials used. A well-established manufacturer not only supplies reliable machinery but also provides comprehensive support during installation, operation, and maintenance.

Clients should evaluate a manufacturer’s reputation, project portfolio, and client testimonials. The ability to deliver customized Industrial Rotary Dryers, adhere to global quality standards, and maintain strong communication are hallmarks of a reliable partner. In regions like Ahmedabad and Gujarat, manufacturers have developed long-standing reputations for professionalism, precision, and commitment to customer satisfaction.

Contribution of Rotary Dryer Suppliers and Exporters

The success of India’s manufacturing sector is also supported by a strong network of Rotary Dryer Suppliers and Rotary Dryer Exporters. These companies ensure that quality products reach domestic and international markets efficiently. Suppliers play a crucial role in providing spare parts, accessories, and maintenance components, helping industries maintain continuous operations.

Exporters, on the other hand, focus on delivering machines that meet global performance and safety standards. The reputation of Indian exporters has grown significantly due to consistent product quality, competitive pricing, and technical expertise. As a result, rotary dryers manufactured in India are now used across the Middle East, Africa, Southeast Asia, and Europe.

The Technological Evolution of Rotary Dryers in India

Modern Indian manufacturers are continuously improving their rotary dryer designs with advancements in automation, material handling, and energy management. The integration of smart sensors and control systems allows industries to monitor temperature, airflow, and drum speed in real-time. This ensures consistent product quality and operational precision.

Energy efficiency remains a major focus area. The use of advanced combustion systems, heat recovery units, and improved insulation helps reduce fuel consumption and emissions. Manufacturers such as Shalimar Engineering are at the forefront of this innovation, producing Industrial Rotary Dryers that are both technologically advanced and environmentally responsible.

Why Indian Manufacturers Are Preferred Globally

India’s position as a major rotary dryer manufacturer stems from its ability to balance cost efficiency with quality manufacturing. The combination of skilled engineers, modern fabrication facilities, and strict quality control measures ensures that Indian dryers compete on par with global brands.

Furthermore, the ability to offer customized solutions, provide reliable after-sales service, and meet international certification standards makes Indian manufacturers a preferred choice for global clients. With competitive pricing and a strong export network, Rotary Dryer Manufacturers in Gujarat continue to expand their footprint across various industrial markets worldwide.

Conclusion

India’s manufacturing sector has achieved global recognition for delivering high-quality, durable, and efficient industrial equipment. The country’s leading Rotary Dryer Manufacturers in India offer reliable drying solutions that cater to diverse industrial applications. With advanced engineering, customization options, and strong service networks, these manufacturers have built a reputation for excellence both domestically and internationally.

Partnering with a trusted rotary dryer manufacturer ensures superior performance, energy efficiency, and long-term reliability. Manufacturers like Shalimar Engineering exemplify India’s engineering capabilities, providing robust Industrial Rotary Dryers that meet global standards. With growing demand and continuous innovation, Indian manufacturers are set to remain at the forefront of industrial drying technology for years to come.

For more information or to get a quote, visit our Enquiry Page