Understanding Rotary Kiln Technology for Optimal Industrial Performance

Industrial processing operations across the globe rely heavily on efficient thermal treatment systems, with rotary kilns standing as one of the most versatile and crucial pieces of equipment in modern manufacturing. These cylindrical furnaces have revolutionized how industries approach high-temperature processing, making them indispensable for sectors ranging from cement production to waste treatment.

What is a Rotary Kiln?

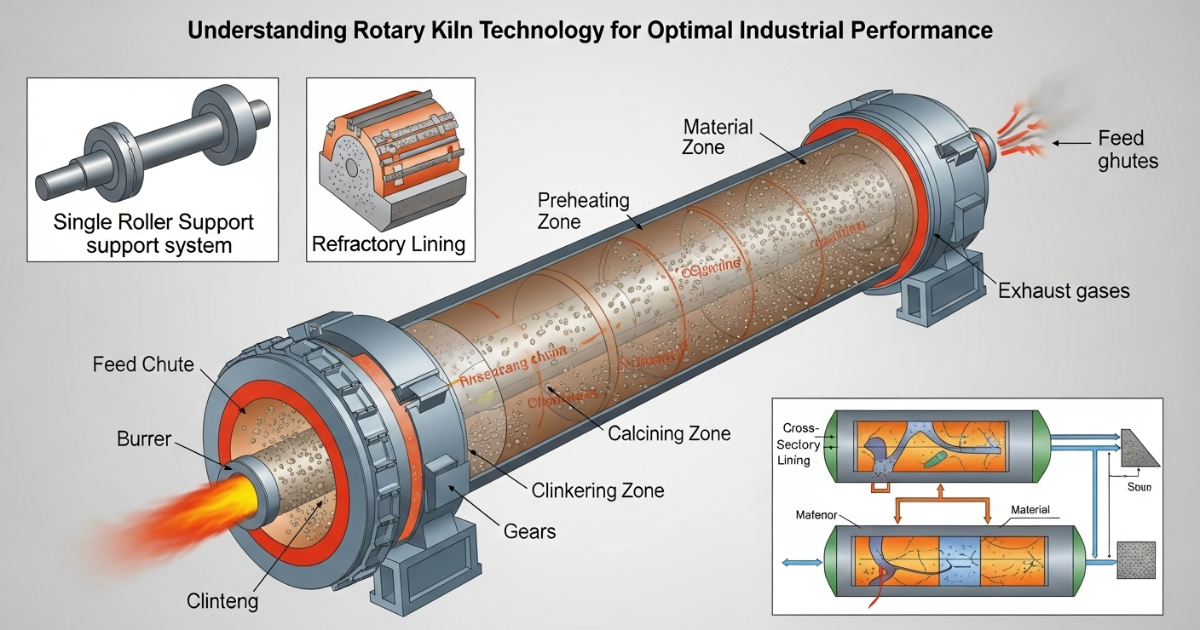

A rotary kiln is a pyroprocessing device used to raise materials to high temperatures in a continuous process. The kiln consists of a large, rotating cylindrical shell that is slightly inclined to the horizontal. This design allows materials to be fed at the upper end and gradually move through the kiln as it rotates, undergoing various thermal processes before being discharged at the lower end.

The fundamental principle behind rotary kiln operation involves three key heat transfer mechanisms: radiation from the flame and hot gases, convection from the gas stream, and conduction through direct contact with the hot kiln shell. This combination ensures uniform heating and efficient thermal processing of materials.

Types of Industrial Rotary Kilns

Understanding the different types of industrial rotary kilns available helps in selecting the most appropriate system for specific applications.

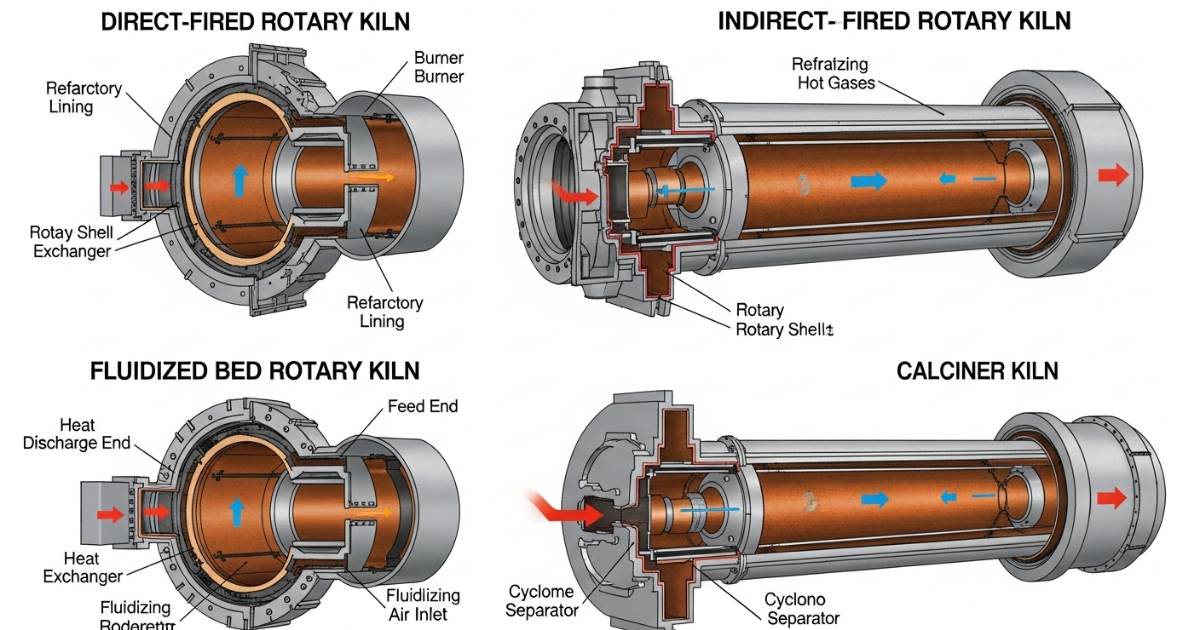

Direct-Fired Rotary Kilns

Direct-fired kilns feature a burner flame that comes into direct contact with the processing material. This design offers excellent heat transfer efficiency and is commonly used for applications where direct flame contact doesn’t adversely affect product quality. These kilns are particularly effective for drying applications and certain chemical processes.

Indirect-Fired Rotary Kilns

Indirect-fired kilns separate the combustion gases from the process material using various methods such as radiant tubes or external heating chambers. This configuration prevents contamination of the product with combustion gases, making it ideal for applications requiring pure processing environments or when handling volatile materials.

Calcining Kilns

Specifically designed for calcination processes, these kilns operate at precisely controlled temperatures to remove chemically bound water or carbon dioxide from materials. Calcining kilns are essential in industries producing lime, alumina, and various ceramic products.

Applications Across Industries

The versatility of rotary kilns makes them essential across numerous industrial sectors, each leveraging specific advantages of this technology.

Cement Manufacturing

The cement industry represents the largest application for rotary kilns globally. These massive systems, often exceeding 200 meters in length, process limestone, clay, and other raw materials at temperatures reaching 1,450°C. The continuous rotation ensures proper mixing and uniform heating, resulting in the formation of cement clinker, the key ingredient in portland cement.

Modern cement kilns incorporate advanced preheater and precalciner systems that improve energy efficiency while maintaining product quality. Leading rotary kiln manufacturers have developed sophisticated designs that reduce fuel consumption and emissions while increasing production capacity.

Metallurgical Processing

In metallurgical applications, rotary kilns process various ores and concentrates to extract valuable metals or prepare materials for further processing. These applications often require precise temperature control and atmosphere management to achieve optimal recovery rates and product quality.

The steel industry utilizes rotary kilns for processing iron ore pellets and direct reduced iron production. These applications demand robust construction and specialized refractory linings to withstand extreme operating conditions.

Chemical Industry

Chemical processing applications leverage rotary kilns for various thermal treatment processes, including activation of carbon materials, processing of specialty chemicals, and thermal decomposition reactions. The controlled environment within the kiln allows for precise reaction conditions and consistent product quality.

Environmental Applications

Increasingly, rotary kilns serve environmental applications such as hazardous waste treatment, soil remediation, and alternative fuel processing. These applications require specialized designs to handle varying feed materials while meeting stringent environmental regulations.

Design Considerations and Technical Features

Selecting the right rotary kiln manufacturer in India requires understanding critical design elements that impact performance, efficiency, and longevity.

Shell Design and Construction

The kiln shell represents the primary structural component, requiring careful engineering to withstand thermal stresses, mechanical loads, and operational demands. High-quality steel construction with appropriate thickness and material grades ensures long service life and reliable operation.

Modern designs incorporate advanced stress analysis and thermal modeling to optimize shell thickness distribution and support arrangements. This engineering approach minimizes thermal stress while ensuring structural integrity throughout the operating temperature range.

Refractory Lining Systems

Refractory linings protect the steel shell from high temperatures while providing thermal insulation and chemical resistance. The selection of refractory materials depends on operating temperatures, chemical environment, and mechanical wear conditions.

Advanced refractory systems utilize multiple zones with different brick compositions optimized for specific thermal and chemical conditions within the kiln. This approach maximizes lining life while maintaining thermal efficiency.

Drive Systems and Mechanical Components

Reliable drive systems ensure consistent rotation speed and smooth operation under varying load conditions. Modern kilns typically employ AC motor drives with variable frequency control, enabling precise speed adjustment and energy optimization.

Supporting systems including thrust rollers, riding rings, and sealing arrangements require careful design and high-quality manufacturing to ensure trouble-free operation. Regular maintenance of these components is crucial for sustained performance.

Control and Instrumentation

Advanced control systems monitor critical parameters including temperature profiles, gas composition, pressure differentials, and material flow rates. This data enables operators to optimize performance while maintaining product quality and safety standards.

Modern installations incorporate distributed control systems (DCS) with advanced process control algorithms that automatically adjust operating parameters based on real-time conditions and production requirements.

Regional Manufacturing Excellence

India has emerged as a global hub for rotary kiln manufacturing, with companies across various states developing world-class capabilities in design, manufacturing, and project execution. The rotary kiln in India market has grown significantly, driven by expanding industrial sectors and increasing demand for efficient thermal processing solutions.

Gujarat’s Industrial Leadership

Gujarat, particularly the Ahmedabad region, has established itself as a premier destination for heavy industrial equipment manufacturing. The state’s robust infrastructure, skilled workforce, and supportive industrial policies create an ideal environment for rotary kiln manufacturers in Gujarat to thrive and innovate. The rotary kiln in Gujarat industry benefits from the state’s strategic location and well-developed industrial ecosystem.

Rotary kiln supplier in Gujarat companies have established comprehensive manufacturing capabilities, from initial design through final commissioning. The concentration of engineering expertise and manufacturing capabilities enables comprehensive project execution, reducing project timelines and enhancing technical support for clients across India and internationally.

Working with a rotary kiln manufacturer in Ahmedabad offers several strategic advantages including proximity to major industrial hubs, access to skilled technical workforce, and established supply chain networks. The rotary kiln supplier in Ahmedabad market is characterized by companies that combine traditional manufacturing expertise with modern technology and quality standards.

Advantages of Indian Manufacturers

Rotary kiln suppliers in India offer several compelling advantages including cost-effective solutions without compromising quality, extensive customization capabilities, and comprehensive project management services. The rotary kiln manufacturer in India sector has evolved to meet international standards while maintaining competitive pricing structures.

Local manufacturing also provides benefits in terms of faster delivery, easier communication, and better understanding of regional operating conditions and requirements. The industrial rotary kiln manufacturing sector in India has developed specialized expertise across various applications, from cement and steel to chemical processing and environmental applications.

Selection Criteria for Optimal Performance

Choosing the right rotary kiln supplier in Ahmedabad or elsewhere requires careful evaluation of multiple factors that influence long-term success and performance. Whether you’re looking for a rotary kiln manufacturer in Gujarat or evaluating rotary kiln suppliers in India, the selection process should focus on technical capabilities, manufacturing quality, and comprehensive support services.

Technical Expertise and Experience

Evaluate potential rotary kiln manufacturers based on their track record in similar applications, technical expertise, and ability to provide customized solutions. Experienced industrial rotary kiln manufacturers understand the nuances of different applications and can optimize designs for specific requirements.

Review past projects, customer references, and technical certifications to assess capabilities and reliability. The best rotary kiln manufacturer in India companies provide detailed technical proposals with performance guarantees and comprehensive support services.

Manufacturing Quality and Standards

Quality manufacturing standards directly impact equipment reliability and performance. Look for rotary kiln manufacturer in Ahmedabad companies with ISO certifications, established quality control procedures, and modern manufacturing facilities equipped with advanced machinery and inspection equipment.

Visit manufacturing facilities when possible to observe production processes, quality control measures, and overall organizational capabilities. This firsthand evaluation provides valuable insights into manufacturing standards and capabilities of rotary kiln suppliers in Gujarat.

After-Sales Support and Service

Comprehensive after-sales support significantly impacts total cost of ownership and operational success. Evaluate potential rotary kiln supplier in India companies based on their service network, spare parts availability, technical support capabilities, and maintenance programs.

The best rotary kiln manufacturers in India provide lifecycle support including operator training, preventive maintenance programs, and emergency service capabilities. This comprehensive approach ensures optimal performance throughout the equipment’s operational life.

Maintenance and Operational Excellence

Maximizing rotary kiln performance requires implementing systematic maintenance strategies and operational best practices.

Preventive Maintenance Programs

Successful rotary kiln operation depends on well-planned maintenance programs addressing critical components including refractory linings, mechanical systems, and instrumentation. Regular inspection schedules help identify potential issues before they impact production or safety.

Key maintenance activities include refractory monitoring and repair, mechanical component lubrication and adjustment, and instrumentation calibration. Establishing maintenance intervals based on operating hours, thermal cycles, and production tonnage ensures optimal equipment availability.

Performance Optimization

Continuous performance monitoring and optimization enable maximum efficiency and product quality. This includes analyzing thermal profiles, combustion efficiency, material residence time, and energy consumption patterns.

Modern installations benefit from advanced process control systems that automatically optimize operating parameters based on real-time conditions and production requirements. These systems improve efficiency while reducing operator workload and variability.

Future Trends and Innovations

The rotary kiln industry continues evolving with new technologies focused on energy efficiency, environmental performance, and operational automation.

Energy Efficiency Improvements

Waste heat recovery systems, advanced combustion technologies, and improved insulation materials are reducing energy consumption while maintaining production capacity. These innovations help industries reduce operating costs and environmental impact.

Environmental Technologies

Advanced emission control systems, alternative fuel capabilities, and process optimization technologies address increasingly stringent environmental regulations while maintaining operational efficiency.

Digital Technologies

Industry 4.0 concepts including predictive maintenance, advanced process control, and remote monitoring capabilities are transforming rotary kiln operations. These technologies improve reliability while reducing maintenance costs and operational complexity.

Conclusion

Understanding rotary kiln technology and selecting the right manufacturer are crucial decisions that impact long-term operational success and profitability. The combination of proven technology, quality manufacturing, and comprehensive support services ensures optimal performance across diverse industrial applications.