Why Choose a Trusted Ribbon Blender Manufacturer for Your Industry? Understanding Ribbon Blenders A ribbon blender is a critical piece of equipment for industries that require uniform mixing of powders,…

How to Choose the Right Rotary Kiln Supplier for Your Industry Understanding Rotary Kilns Rotary kilns are essential for industries that require thermal processing of materials. These cylindrical, slowly rotating…

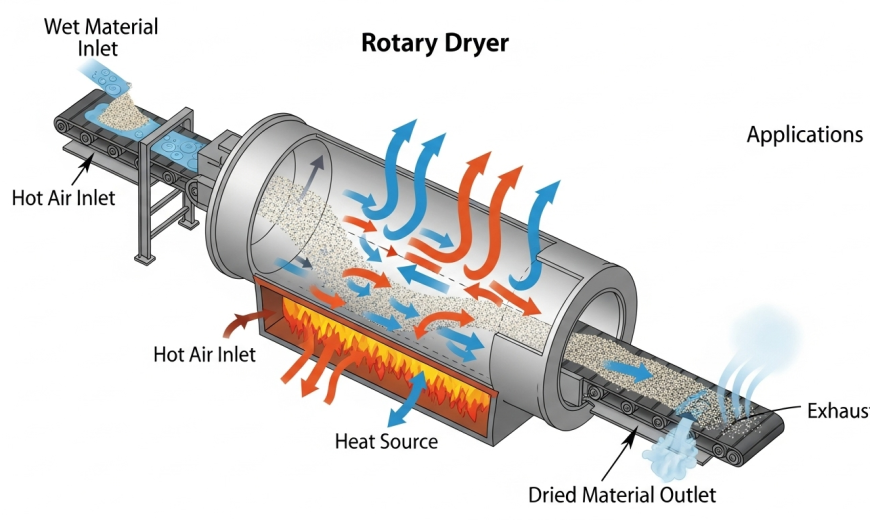

How Rotary Dryers Work: Principle, Process, and Applications Rotary Dryer Fundamentals In industrial processes, moisture control is one of the most crucial factors for ensuring quality and efficiency. Industries ranging…

Best Iron Ore Manufacturer & Supplier in India India’s iron ore sector is one of the key drivers of industrial growth, supporting the country’s steel production, construction, and infrastructure development.…

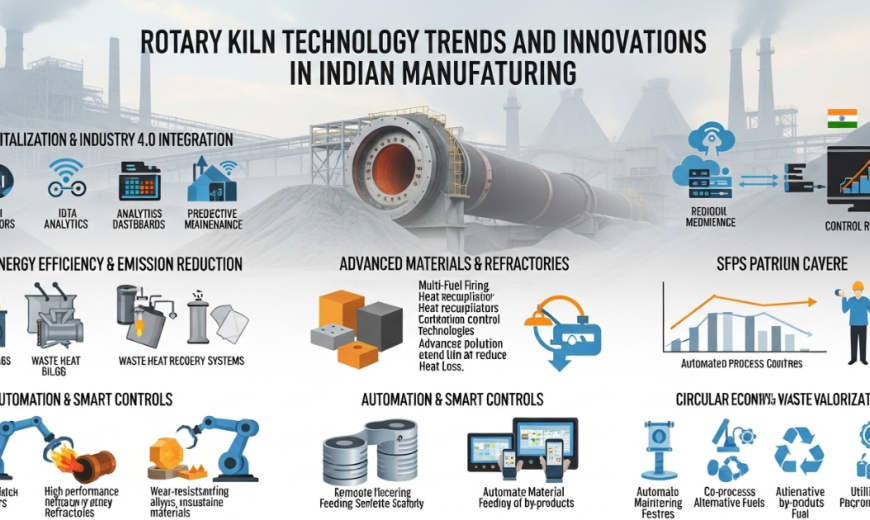

Rotary Kiln Technology Trends and Innovations in Indian Manufacturing The Indian manufacturing landscape is witnessing a remarkable transformation, with rotary kiln technology at the forefront of industrial innovation. As the…

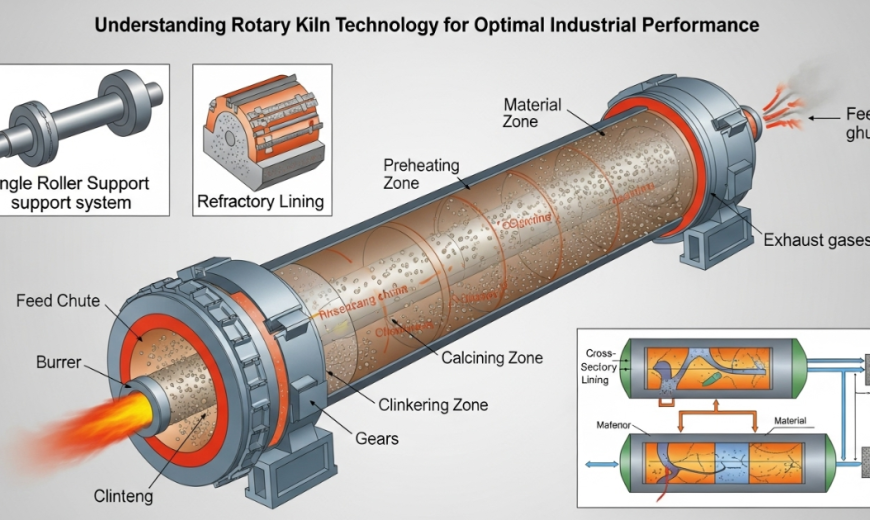

Understanding Rotary Kiln Technology for Optimal Industrial Performance Industrial processing operations across the globe rely heavily on efficient thermal treatment systems, with rotary kilns standing as one of the most…

Industrial Roller Crushers: Essential Equipment for Efficient Material Processing Industrial crushing equipment plays a vital role in mining, cement, metallurgy, power generation, and recycling industries. Among the wide range of…

Importance of Roller Crushers in Industrial Applications In the world of industrial machinery, productivity, efficiency, and reliability depend heavily on the quality of the equipment being used. Among the wide…

Industrial Applications of 3 Roller Mill Plants Roller crushers, including advanced systems like 3 Roller Mill Plants, are essential equipment in industries requiring efficient and uniform particle size reduction. These…

High-Performance 3 Roller Mill Plant for Precision Grinding Across Industries A 3 Roller Mill Plant is an advanced grinding system designed to achieve precise and uniform particle size reduction for…